If that "uneven waviness" is what I think it might be, I'd suspect a sharper tool would solve a lot of your frustration. I know, I know.....the subject of what is and isn't sharp is a very touchy subject to a lot of turners....even to those who have years of turning experience under their belt.

Most turners use an edge created from their slow-speed grinder and go directly from there to the lathe. Some will swear they have sharp tools, and even use words like "scary sharp" to describe their cutting edges.....but, I have my suspicions.

For myself, the grinder is nothing more than a tool that speeds up removing metal up to the edge, but does not create the cutting edge itself. My gouge cutting edges are all hand honed.....the modern diamond hones are the best at this task......but, even the old Arkansas honing stones will do just as well. My finest scraper burs are created with diamond hones on the top edge and then manually raised on a carbide post. (For general rough work, the scraper burs created on the grinder will suffice for that purpose.)

-o-

Added content: If you want the sharpest edges possible.....then be prepared to sharpen much more often than you ever thought you would, or should. It is these fine edges, when maintained, can and do produce the finest surface quality. When you reach that level of cutting edge maintenance, then you will make it possible to create surfaces direct from the tool that require a bare minimum of sanding.

I actually do sharpen a lot. Constantly. Especially when turning bowls, I sharpen many times for both the inside and the outside (unless its a small bowl, I guess.)

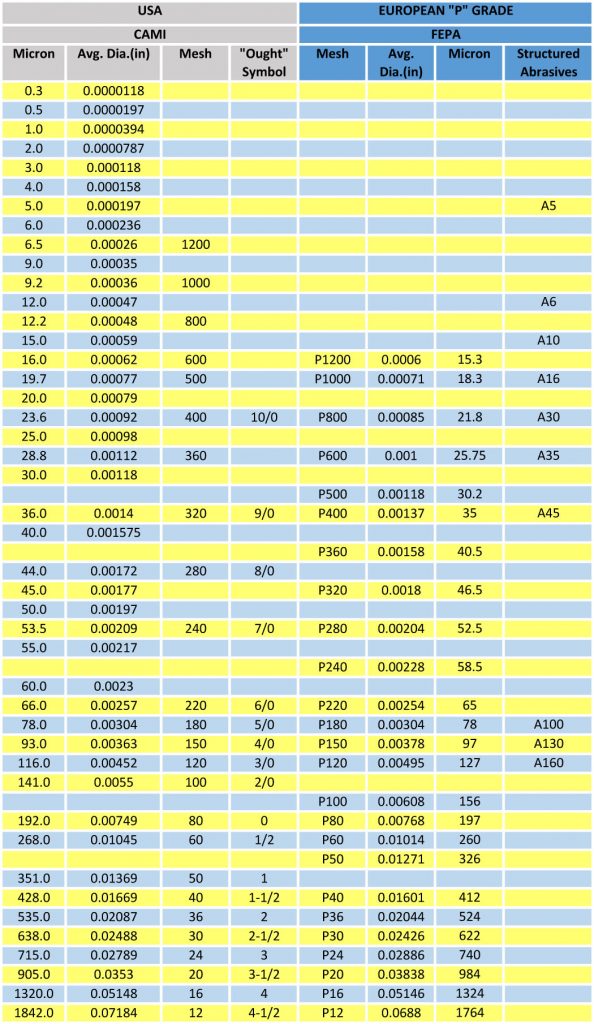

I have not, however, used a hone to fine tune the edge. I have CBN wheels, 350 and 600, and will use the 350 if I need to really re-grind the shape, and the 600 to get a finer edge. I don't know how the 600 grit CBN compares to a diamond hone though... I think I did try to hone in the past, but, my concern always was losing the angle of the edge vs. the bevel. I don't think I ever found anyone demonstrating how to properly hone a gouge back then, and just stuck with the grinding wheels. If there is a technique to properly honing a gouge, though, that wont' muck it all up, I'll happily give it a try.