I have been following this thread closely as I have a heavily modified Delta DL 40 and have just stumbled across a used Oneway 2436 3 hp - which I have first offer of refusal on, and am going to look at it this weekend. I am like a kid waiting for Christmas!

-

December 2025 Turning Challenge: Single Tree! (click here for details) -

Congratulations to Bob Henrickson, People's Choice in the November 2025 Turning Challenge (click here for details) -

Congratulations to Guillaume Fontaine for "Old Tea Pot" being selected as Turning of the Week for December 15, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What's in a Lathe?

- Thread starter Kent Reisdorph

- Start date

I have also watched a ton of YouTube videos. It really helped me to realize that turning was the form of woodworking I enjoy most. Every time I go out to my shop I come up with new non-turning related ideas of things to make. Some day I'll get around to doing them!

If you haven't already discovered www.turnawoodbowl.com, I highly recommend you check it out. Kent Weakley has a lot of free videos on his site and on YouTube. He also has a handful of paid courses that are worth the money.

I have been turning for 30+ years. It all comes down to two things. Money and intent. The quality can be found at any level but you will get what you pay for. For American made, unless you go back in time, will cost you. The newer stuff has its merits and benefits from refinement over the years. You have to decide, are you a $300 dollar turner, $1000, $5000 or $8000 turner? How many will you buy along the way? As with many things buy the best you can afford and see yourself using down the road. I have one saying that comes back to me over and over. The quality of work is in the mechanic not the tool. Many of the folks chiming in here can literally turn a sows ear into a silk purse with it is a Harbor Freight or an American Beauty or anything in between. Start somewhere. Like throwing a dart, there are many excellent values on the used market. Older units with lots of life left. PM is designed, engineered here in the states and then produced in their manufacturing facility in Taiwan. It is the same for many but several are made in China. The European models are excellent also. At the levels above $3000 you will have a unit you can pass down to your kids or sell for close to what you have invested. The key take away, START TURNING! Enjoy.

This discussion of what what/who makes the best lathe, remind me of the WWII story about a bunch of GIs putting together the perfect woman. They put all the body parts together from different movie stars etc. A soldier overhearing the debate finally lamented that he would be happy to have all the parts they didn’t use. Same here!

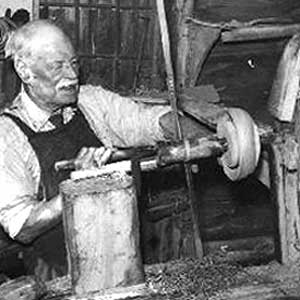

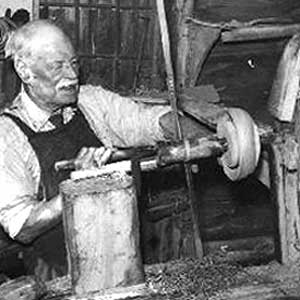

Check out this lathe, and the work produced on it.

The Craft - Robin Wood

Woodturning history and techniques using hand forged tools and pole lathe

www.robin-wood.co.uk

A couple things worth noting in the Robin Wood video. First was the mechanism reversing the rotation of the bowl which is ridiculous, there were treadle mechanisms that maintained direction of rotation.

The second was the tools. Some hook some not hook, but all had small included angle on the cutting edge. I bet he didn't have the nonsense of a sharpening jig, more likely he honed the cutting edge when needed. You have to have a free cutting tool to work at his slow speed. Anybody think the current latest and greatest gouges would have performed well if at all on his lathe?

The second was the tools. Some hook some not hook, but all had small included angle on the cutting edge. I bet he didn't have the nonsense of a sharpening jig, more likely he honed the cutting edge when needed. You have to have a free cutting tool to work at his slow speed. Anybody think the current latest and greatest gouges would have performed well if at all on his lathe?

A couple things worth noting in the Robin Wood video. First was the mechanism reversing the rotation of the bowl which is ridiculous, there were treadle mechanisms that maintained direction of rotation.

The second was the tools. Some hook some not hook, but all had small included angle on the cutting edge. I bet he didn't have the nonsense of a sharpening jig, more likely he honed th

Robin has chosen to keep up the tradition of using a Pole Lathe, Not a treadle lathe.

Perhaps you should have read the text?

“When George Lailey died in 1958 a craft going back more than 2000 years died with him. He was the last person in England to make a living turning wooden bowls on a foot powered pole lathe. In medieval times nearly everybody in Britain ate from wooden bowls every day. They were beautiful, functional bowls that linger on in memories of Goldilocks but were killed off by the industrial revolution and cheap pottery.

I became fascinated by the craft whilst working in woodland conservation and set about reviving the lost technique, first learning the blacksmithing skills I needed to forge the specialised turning tools.”

I’ve gone through 6 lathe in 53 years of turning, from Sears to 3520 and now Robust long bed. My Robust is 7 years old I could sell it for more than I paid for it, (welcome to inflation). Think of good lathes as investments.

Thanks for posting it. There was something to be gained from it.Robin has chosen to keep up the tradition of using a Pole Lathe, Not a treadle lathe.

Perhaps you should have read the text?

I did read it and I still think it was ridiculous in the mid 1900's to use a lathe like that. Tradition is one thing, torture is another. I've never looked closely at a pole lathe, but have seen similar mechanism that don't reverse the work.

As to the turner's tools, they were good. Current turners could learn something from them.

I do need much more time with hook tools. As near as I can tell, they are a very under used tool for just about all turners.... I know.... I should make my own!

robo hippy

robo hippy

I’ve never used one, but I’d like to. From what I’ve read they can be quite aggressive. I believe they are quite popular in Europe?I do need much more time with hook tools. As near as I can tell, they are a very under used tool for just about all turners.... I know.... I should make my own!

robo hippy

Wiedemann make HSS interchangeable tip hook tools. I’ve been meaning to make something similar out of O1 Tool Steel to see how they work.

Odie

Panning for Montana gold, with Betsy, the mule!

We all have our favorites, but I think in a blind test, 99.9% of woodturners would be unable to determine what kind of lathe bed they were turning on.

(It's commendable to see you participate in these conversations, Brent......as well as just absorbing the information being discussed, whether or not you actively participate in the conversation. Most manufacturers are probably more personally engaged in design theory, rather than practical application. You are different.)

Hello Brent,

Concerning your comment about 99.9% of turners not being able to tell the difference in the material used for a lathe bed.....well, I think you are correct, and I also feel that I'm in that 0.1% category who could.....and, I also feel this is an important consideration for woodturners who strive to achieve the ever-elusive perfect cut in cross-grain bowl turning.

It goes beyond just the bedways, because the significance of the lathe bed is on the same level as how the lathe headstock and spindle is constructed....and the bearing arrangement between them. You are absolutely correct where the interaction of the cutting edge with the wood is of great importance, as well......and it's not just a matter of an out-of-balance condition of the turning block of wood......there are many other factors that influence the ability to achieve the "perfect cut". @William Rogers has mentioned a few of those other factors......but, even they have their limitations as to how they ultimately influence the conditions that can lead to a perfect cut. My definition of a perfect cut is one that is devoid of any tearout, and requires a bare minimum of sanding. This completely eliminates the need for any power sanding at all. Hand sanding starting at grits at or higher than 180gt will make it possible to maintain a perfect geometry.....and, it is precisely this perfect geometry which allows the turned details to be pleasing to the eye. Especially of note in bowl turning, is the grain of the wood alternates between long grain and end grain.......and that creates an alternating resistance to the cutting tool. Because of this, and in combination with any present vibration, it's been the bane of woodturners to create a tooled surface that is free of any tearout. When there is tearout, it requires coarse sanding, and coarse power sanding just can't get rid of tearout without destroying the perfect geometry that a tooled surface is capable of.

Vibration, I've come to have a very special relationship with.....and, controlling it through a combination of rpm adjustments, sharp tools, tool design, and technique has been my greatest challenge in woodturning. The manipulation of these multiple sources of input, in order to reach the best harmonic combination of these things, can't be learned in a seminar or class instruction......they must be mentally absorbed over time and experimentation in order to gain a complete insight into how these things are related to one another. I call this "spiritual turning", and it's something that seems the 99.9% of turners you mentioned are incapable of comprehending at their current level of understanding.

-o-

Last edited:

Curt,Lathes say a lot about human nature. I think of them as Ford vs Chevy or Mercedes vs Lexus kind of thing. There's a lot of flaunting what you can afford and there's a lot of real cheapskates like me that don't want to spend a dime more than they have too. But in the end what really matters is that the lathes comes to life when you hit the start button. Watch a youtube video of Mike Mahoney coring oak bowls on one of his many Vicmarcs or watch one of those videos of some 80 year old Asian woman cranking out tea bowls on a machine that would scare the hell out of me. If you have the drive or desire to create wood turned art you find a way.

I would agree. I started many years ago with a very used General 160. It was a great lathe, and they do a fantastic jobs on their castings.

I came across a used Oneway 1024 and it is an fantastic lathe, but I love my cast Iron (just personal feelings).

I saved and bought a Bare Vicmarc VL300, I can't believe those could be purchased for 1500.00 new. I did not have much money starting out after school, but I worked at Cincinnati Milacron R&D and was happy to buy used/not working old machines and put in sweat equity to build out my Shop.

My late wife was an artist, and we could sit in the booths together on the weekends. She often asked me if my hobby was woodturning/woodworking or Fixing old woodworking tools and selling them. I did marry up.....

Back to my cast iron, and I really like the Tapered Bearons in them. If you really think about, the business parts of the lathe are:

- stand (get to your height and stable)

- motor (steady and strong power)

- bearings - Hold your spindle and work

The Cast Iron's lathes give you a different "feel" (not saying better or worse, just different).

I love the Vicmarcs' rock-solid cast iron feel, the quality of the finish, and the tapered bearings, but I will be the first to admit it is a Ford/Chevy thing.

I really admire the "newer than mine" Vicmarc VL240, but with a VL150 and VL300 and I use my old Oneway 1018. I don't know if I will have space to add the VL240, and don't know what I would get rid of to add it

Enjoy whatever you end up and don't look back.

Michael

(It's commendable to see you participate in these conversations, Brent......as well as just absorbing the information being discussed, whether or not you actively participate in the conversation. Most manufacturers are probably more personally engaged in design theory, rather than practical application. You are different.)

Hello Brent,

Concerning your comment about 99.9% of turners not being able to tell the difference in the material used for a lathe bed.....well, I think you are correct, and I also feel that I'm in that 0.1% category who could.....and, I also feel this is an important consideration for woodturners who strive to achieve the ever-elusive perfect cut in cross-grain bowl turning.

It goes beyond just the bedways, because the significance of the lathe bed is on the same level as how the lathe headstock and spindle is constructed....and the bearing arrangement between them. You are absolutely correct where the interaction of the cutting edge with the wood is of great importance, as well......and it's not just a matter of an out-of-balance condition of the turning block of wood......there are many other factors that influence the ability to achieve the "perfect cut". @William Rogers has mentioned a few of those other factors......but, even they have their limitations as to how they ultimately influence the conditions that can lead to a perfect cut. My definition of a perfect cut is one that is devoid of any tearout, and requires a bare minimum of sanding. This completely eliminates the need for any power sanding at all. Hand sanding starting at grits at or higher than 180gt will make it possible to maintain a perfect geometry.....and, it is precisely this perfect geometry which allows the turned details to be pleasing to the eye. Especially of note in bowl turning, is the grain of the wood alternates between long grain and end grain.......and that creates an alternating resistance to the cutting tool. Because of this, and in combination with any present vibration, it's been the bane of woodturners to create a tooled surface that is free of any tearout. When there is tearout, it requires coarse sanding, and coarse power sanding just can't get rid of tearout without destroying the perfect geometry that a tooled surface is capable of.

Vibration, I've come to have a very special relationship with.....and, controlling it through a combination of rpm adjustments, sharp tools, tool design, and technique has been my greatest challenge in woodturning. The manipulation of these multiple sources of input, in order to reach the best harmonic combination of these things, can't be learned in a seminar or class instruction......they must be mentally absorbed over time and experimentation in order to gain a complete insight into how these things are related to one another. I call this "spiritual turning", and it's something that seems the 99.9% of turners you mentioned are incapable of comprehending at their current level of understanding.

-o-

Great post. And very interesting.

I cannot say that I'm at a skill level with my tools where the small vibrations from the metals used in the machine itself, would be the thing that primarily hang me up. I am not sure what the Powermatic 3520C uses materials wise, but compared to all other lathes I've used its an incredibly stable beast. I wonder how it compares to one of the truly high end lathes though. Even despite that, though...I still have problems with turning some woods (notably softer woods), where I'll get an uneven waviness in the wood as I turn. I am pretty sure that is ME, though, not the machine or its materials, just because my hands aren't perfectly steady. I hate the way the wood gets when this happens, and it requires even more careful turning to eliminate the wave that's then become embedded in the wood. I think this arises because I push the tool too hard, and then the wood pushes back, etc.

I would love to get to the point some day here (I've only been turning since about March 2020) where I can get those clean, geometrically perfect and tearout-free cuts and either not have to sand, or be able to start at a significantly higher grit if I feel the surface needs further smoothing than I can get with a tool (whenever I use a friction polish or something like that, where the ability of the finish to soak into the wood is not an issue.) I never power sand, though...I always sand by hand. It takes a lot longer to clean up tearout, but I feel it helps me preserve the geometry better (still not perfect if I could just tool it right in the first place!)

Odie

Panning for Montana gold, with Betsy, the mule!

I really admire the "newer than mine" Vicmarc VL240, but with a VL150 and VL300 and I use my old Oneway 1018. I don't know if I will have space to add the VL240, and don't know what I would get rid of to add it

IMHO, the only benefit of the VL240 over the VL300 is the rotating headstock. They are both well built top tier lathes. Except for the swing capacity, my old Woodfast 908 lathe is the equal of the VL300.....heavy, well built, and both have that sense of stability with the cast iron components.

Many turners don't see any benefit to a rotating headstock, but I feel it's a great addition to a lathe because a bowl interior can be addressed without changing the location of the turner himself. It would be a wonderful thing for me because I rely on so many accessories for my turning.......and all of them would have to be relocated with a sliding headstock.

-o-

Odie

Panning for Montana gold, with Betsy, the mule!

I still have problems with turning some woods (notably softer woods), where I'll get an uneven waviness in the wood as I turn.

I think this arises because I push the tool too hard, and then the wood pushes back, etc.

If that "uneven waviness" is what I think it might be, I'd suspect a sharper tool would solve a lot of your frustration. I know, I know.....the subject of what is and isn't sharp is a very touchy subject to a lot of turners....even to those who have years of turning experience under their belt.

Most turners use an edge created from their slow-speed grinder and go directly from there to the lathe. Some will swear they have sharp tools, and even use words like "scary sharp" to describe their cutting edges.....but, I have my suspicions.

For myself, the grinder is nothing more than a tool that speeds up removing metal up to the edge, but does not create the cutting edge itself. My gouge cutting edges are all hand honed.....the modern diamond hones are the best at this task......but, even the old Arkansas honing stones will do just as well. My finest scraper burs are created with diamond hones on the top edge and then manually raised on a carbide post. (For general rough work, the scraper burs created on the grinder will suffice for that purpose.)

-o-

Added content: If you want the sharpest edges possible.....then be prepared to sharpen much more often than you ever thought you would, or should. It is these fine edges, when maintained, can and do produce the finest surface quality. When you reach that level of cutting edge maintenance, then you will make it possible to create surfaces direct from the tool that require a bare minimum of sanding.

Last edited:

Most turners use an edge created from their slow-speed grinder and go directly from there to the lathe. Some will swear they have sharp tools, and even use words like "scary sharp" to describe their cutting edges.....but, I have my suspicions.

For myself, the grinder is nothing more than a tool the speeds up removing metal up to the edge, but does not create the cutting edge itself. My gouge cutting edges are all hand honed.....the modern diamond hones are the best at this task......but, even the old Arkansas honing stones will do just as well. My finest scraper burs are created with diamond hones on the top edge and then manually raised on a carbide post. (For general rough work, the scraper burs created on the grinder will suffice for that purpose.)

This is something every aspiring turner should read and understand.

If I was king of this forum I'd have this in large bold print for everyone to read as you logged in. In fact, make it a prerequisite to posting to read and understand it.

Unfortunately a good many have drunk the Kool-aid and bought the complete package, grinder, CBN and sharpening jig.

Some may disagree, what does Odie know anyway? He's just a hack turner from Montana

- Joined

- Apr 27, 2004

- Messages

- 9,304

- Likes

- 6,059

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

(notably softer woods), where I'll get an uneven waviness in the wood as I turn. I am pretty sure that is ME, though, not the machine or its materials, just because my hands aren't perfectly steady. I hate the way the wood gets when this happens, and it requires even more careful turning to eliminate the wave that's then become embedded in the wood. I think this arises because I push the tool too hard, and then the wood pushes back, etc.

The Powermatic is a fine lathe. I get great results when I demo on one.

Common causes of ripples

Bevel drag - pushing the bevel against the wood and or resin building up on the bevel

Too fast a feed rate

Not riding the bevel.

-Sharp tools are essential and an edge off the grinder can give you a nicely cut surface.

- ABC. Anchor ( tool on tool rest)

Bevel ( bevel on the wood not cutting)

Cut ( engage the cutting edge while moving cut forward. Rais the handle slightly and roll the tool to start the cut)

- Proper feed rate

I cut mostly with my body and don’t move the hands much.

I hold the handle against my side and rest the forward hand on the toolrest then turn with my dodgy moving the tool.

Forward foot pointing somewhat in the direction of the cut. Then shift weight from the rear foot to the forward foot to make the cut.

Turning at the hips cuts the curves.

Once you create ripples it’s hard to turn then away. Cutting over the just cuts the rippled surface,

I start at Don end cut a smooth strip then when I feel the uneven surface I stup cutting back the bevel onto the smooth surface and pick up the cut until I feel the rough. By repeatedly cutting from smooth to rough you advance thd smooth surface on every pass and by stopping when you feel the rough you don’t follow the ripples.

You live within 90 minutes of some of the finest turners in the world.

If you have an opportunity to work with them in a class, workshop, it can improve your turned surfaces.

Rocky Mountain woodturning symposium start in 8 days. Great place to learn.

I don't understand a few lines up you're disparaging a guy for using a pole lathe and now you're espousing adding to the process of today's sharpening (which has jumped appreciatively in the last 25 years) where honing in the past was used because there was nothing like slow speed grinders and CBN wheels for turning tools. Now for me I have found that the sharper the tool the faster it dulls. For me my 180 grit CBN wheel and slow speed grinder give me an edge that is sharp and stays sharp longer, no need to hone. Now that's just me.This is something every aspiring turner should read and understand.

If I was king of this forum I'd have this in large bold print for everyone to read as you logged in. In fact, make it a prerequisite to posting to read and understand it.

Unfortunately a good many have drunk the Kool-aid and bought the complete package, grinder, CBN and sharpening jig.

Some may disagree, what does Odie know anyway? He's just a hack turner from Montana

Okay, in a time known as the 20th century there were simple mechanisms that could have eliminated the reverse motion of the workpiece on the pole lathe shown. So I thought it was silly. But I did like the tools being used.I don't understand a few lines up you're disparaging a guy for using a pole lathe and now you're espousing adding to the process of today's sharpening (which has jumped appreciatively in the last 25 years) where honing in the past was used because there was nothing like slow speed grinders and CBN wheels for turning tools. Now for me I have found that the sharper the tool the faster it dulls. For me my 180 grit CBN wheel and slow speed grinder give me an edge that is sharp and stays sharp longer, no need to hone. Now that's just me.

I've had a bit of experience with the type tools the pole turner was using, variations of thin hook tools. I rescued a 1930's era automatic lathe that was on its way to the scrap yard. That lathe used tools like the pole turner used made of carbon steel that were initially ground to shape (they had slow speed grinders) then hand or power honed. for edge sharpness. Air dried birch was the recommended ideal wood for that type lathe. The closest type wood available in my west coast area was air dried eastern maple. The cutters I made for the lathe were made from auto leaf springs that would cut all day with a honing for the next day. It all has to do with the tool geometry which were traditional even for hand turners.

In playing with that lathe I came to find out about tooling for other lathes used for mass production turning like Mattison type shaping lathes, back knife lathes and auto variety lathes that all used similar cutters that were honed rather than ground when needed. The concept of taking a grinder to a lathe tool makes no sense to me when honing would do the job. I can't speak for Odie, I do agree with his method of honing to get the final sharp edge.

- Joined

- Apr 27, 2004

- Messages

- 9,304

- Likes

- 6,059

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

Most turners use an edge created from their slow-speed grinder and go directly from there to the lathe. Some will swear they have sharp tools,

I polish the flute of the bowl gouge with slip stone every few sharpenings. I then sharpen the cutting edge on an 80 grit CBN.slow speed grinders and CBN wheels for turning tools.

this is sharp enough to get a surface I can sand starting with 320 if the deck is favorably stacked.

Small turning, face grain cut, pull cut with Sharp wing

The wing of the Ellsworth grind is in skew range of bevel angle 30-25 degrees

This is the 320 tool surface being turned on a 3” diameter cherry ornament disc

Begin gently curving the surface

Refine the curve

This is just a fun cut starting in the middle of the disc

Then shear scrape to a surface I than can be sanded with 320

Last edited:

Great post. And very interesting.

I think this arises because I push the tool too hard, and then the wood pushes back, etc.

I do this too much. I have tried to remind myself not to push into the bowl by loosening my grip on the tool handle. Still working on it.

Many turners don't see any benefit to a rotating headstock, but I feel it's a great addition to a lathe because a bowl interior can be addressed without changing the location of the turner himself.

I'm rotating my headstock more and more (have had the lathe 4 months). It's particularly convenient when sanding, and when hogging out the interior on larger bowls. For small bowls, I usually leave the headstock in the normal position.

If that "uneven waviness" is what I think it might be, I'd suspect a sharper tool would solve a lot of your frustration. I know, I know.....the subject of what is and isn't sharp is a very touchy subject to a lot of turners....even to those who have years of turning experience under their belt.

Most turners use an edge created from their slow-speed grinder and go directly from there to the lathe. Some will swear they have sharp tools, and even use words like "scary sharp" to describe their cutting edges.....but, I have my suspicions.

For myself, the grinder is nothing more than a tool that speeds up removing metal up to the edge, but does not create the cutting edge itself. My gouge cutting edges are all hand honed.....the modern diamond hones are the best at this task......but, even the old Arkansas honing stones will do just as well. My finest scraper burs are created with diamond hones on the top edge and then manually raised on a carbide post. (For general rough work, the scraper burs created on the grinder will suffice for that purpose.)

-o-

Added content: If you want the sharpest edges possible.....then be prepared to sharpen much more often than you ever thought you would, or should. It is these fine edges, when maintained, can and do produce the finest surface quality. When you reach that level of cutting edge maintenance, then you will make it possible to create surfaces direct from the tool that require a bare minimum of sanding.

I have read these discussions on honing, and have decided I don't need it. However, I cannot dispute that you, Odie, are one who hones, and you are also one of the very few who can start sanding at 220. I think I'm convinced.

- Joined

- Apr 27, 2004

- Messages

- 9,304

- Likes

- 6,059

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

Odie, are one who hones, and you are also one of the very few who can start sanding at 220. I think I'm convinced.

I sand my HFs and NE bowls off the lathe after they dry for 3-4 days.

On some I may have to spot sand areas with 180. But most surfaces I start with 220

Finials I sand with 320. Although some coves I’ll do with 220.

I sand my HFs and NE bowls off the lathe after they dry for 3-4 days.

On some I may have to spot sand areas with 180. But most surfaces I start with 220

Finials I sand with 320. Although some coves I’ll do with 220.

I am still aspiring to starting at 180.

So you are using the burr off an 80# wheel most of the time, and getting very good results. The results are what count. John Lucas did some tests recently and concluded that ground edges gave as clean a cut as honed edges. I wonder how Odie's work would turn out if he used your methods.I polish the flute of the bowl gouge with slip stone every few sharpenings. I then sharpen the cutting edge on an 80 grit CBN.

this is sharp enough to get a surface I can sand starting with 320 if the deck is favorably stacked.

Small turning, face grain cut, pull cut with Sharp wing

The wing of the Ellsworth grind is in skew range of bevel angle 30-25 degrees

This is the 320 tool surface being turned on a 3” diameter cherry ornament disc

Begin gently curving the surface

View attachment 66836

Refine the curve

View attachment 66839

This is just a fun cut starting in the middle of the disc

View attachment 66840

Then shear scrape to a surface I than can be sanded with 320

View attachment 66841

I have been using traditional carving tools extensively on variable density spalted maple. maintaining the edge by stropping on a wheel charged with green AOx compound (nominal 0.5 microns). There is a night and day difference in the results between "sharp" and "very sharp". Why is it different for turning, I wonder?

Odie

Panning for Montana gold, with Betsy, the mule!

There is a night and day difference in the results between "sharp" and "very sharp". Why is it different for turning, I wonder?

Well.....the truth is, it's not different.

Plain and simple, the sharper the tool, the better the results.

The difference between carving tools and lathe tools, is the frequency at which a turner will be resharpening.....that is, if they desire to maintain that "very sharp" edge. Most new-age turners will do just about anything, and throw money at the proposition of not having to sharpen their tools as much as required.....and they will be satisfied with tools that are less sharp than they could be. In older times, there was no choice but to sharpen often, and they did what they had to do....they sharpened more frequetly if the very best results were the object.

On a lathe, the speed at which the cutting edge cuts the wood is much faster, and because of that, a "sharp" tool will still cut, but the results will never be as good as a "very sharp" tool.

-o-

- Joined

- Apr 27, 2004

- Messages

- 9,304

- Likes

- 6,059

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

Yes. Remember the 320 example is a stacked deck. Face grain, pull cut, small form.So you are using the burr off an 80# wheel most of the time, and getting very good results.

I do hone the skew to remove the burr otherwise it won’t cut well on the side where the burr Is down.

@john lucas experiment supports what I have found to work of off the wheel.

Hand Carving tools are another animal you want to be able to shave the wood.

Those edges need to be stropped.

Some times I will get a nice little spiral star shape from ripples in the bottom of the bowl. Wish I could do that on purpose. As for other "vibrations" I think there are 2 basic cuts when bowl turning. Roughing cuts and finish cuts. My roughing cuts have gotten a lot cleaner as my experience level grows, but the finish cuts are always "the bevel should rub the wood, but the wood should not know it". Most tend to rush the finish cut, and you have to take that one very easy, and some times I will take a couple of finish cuts.

robo hippy

robo hippy

Sharp is one thing, but I don’t think it is the whole story. The angle of the gouge and the geometry produced by the sharpening method is equally important IMO. I use the Hannes Jig and a 180 CBN wheel. I usually only hone between trips to the grinder and only the outside as the geometry of the Hannes Jig makes it impossible to hone the inside of a gouge. I agree with @Bill Blasic a sharper tool will dull faster. I feel I have a good balance with my methods.

Last edited:

Or we could all forget this sharpening and honing business altogether and just use carbide...

(tongue in cheek)

(tongue in cheek)

What is "wow"? They have the same geometry as his hss cutters - do they cut any differently, or just last longer? Can you sharpen them?AZ Carbide is beta testing some John Jordan carbide inserts. I bought one of each and Wow!

View attachment 66878

You can not sharpen these conventionally (they are carbide after all!). Attempt to do so will ruin a CBN wheel. They can be touched up with a diamond hone across the top per Ron of AZ Carbide. I purchased some at SWAT but haven't used them yet.

I was reading a discussion about today's lathes and lathes of old. For starters, let me provide context.

There are many classes of lathe, but for this discussion, let's use these three:

I started with a #1. It is a Wen 14x20. It's a decent lathe for $600 but quickly outgrown. Then I moved to #2 when I bought my Rikon 70-1824.

- Trash lathes. You know who they are and we don't use these.

- Good midi lathes. These are the 14-20" swing lathes by reputable manufacturers like Rikon, Jet, Laguna, Powermatic, and so on.

- EDIT: I included up to 20" in the midis, but as Bill B pointed out, the 18 and 20" lathes are probably considered full-size lathes.

- Top end full-sized lathes. Robust, OneWay, et al.

My experience is limited to exactly two lathes, so I depend on you all. I have two questions.

It would be great if you could leave your emotions out of your answers. You may love Powermatic, Robust, etc., but I'm asking for objective feedback, not fanboy opinions.

- The Powermatic 3520(a,b,c) is very popular. But I wonder, is that just legacy or is it justified today when compared to other manufacturers? Is the Powermatic better than the Jet, Laguna, or Rikon of the same size?

- Taking that same question to the next level, are the Robust and OneWay lathes that much better than, say, the Powermatic? Put another way, are the top end lathes really $3-4,000 BETTER than the Powermatic, et al?

Hello, thanks for the question! I also have a Rikon (70-150 SVR), and I’m always keeping an eye on the lathes you mentioned. Once, I saw a Laguna at a good price, and I’ve also checked out Oneway and the smaller Powermatic models. As for Robust, that’s still a bit out of reach for me at the moment. I always wonder if there’s a substantial difference and if the experience would be noticeably different.

Hope this day come soon!I actually bought a Rikon earlier this year. I wouldn't have considered a Robust or OneWay at this stage simply due to price. This question is more out of curiosity, and also for future consideration if I someday want to buy the Maybach of lathes. One day I will wake up and decide it's time to treat myself and buy a Robust. ;-)

Sharp and hold their edge. At least so far.What is "wow"?

I would NOT sharpen them on CBN wheels. The carbide can seriously dull your wheels. Diamond is perfect for carbide. There are now carbide lapping plates up to 8000 grit. Not sure how fine the carbide cutters are sharpened to.

robo hippy

robo hippy

Its so easy to do. I heard something, from a well known turner, Stuart Batty, some years ago, that you should never "ride" the bevel but instead "float" the bevel. It is easy to ride it, and then you have those problems. Its a lot harder to "float" it, so that its there to maintain the position of the tool, but it is not there pushing directly into the wood. Your cut then moves ACROSS the wood. Still mastering it. I spent a lot of time making pens, which are just different, and have only recently gotten back into other items, and I'm now having to re-learn how to float the bevel.I do this too much. I have tried to remind myself not to push into the bowl by loosening my grip on the tool handle. Still working on it.