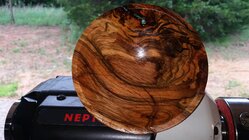

Just finished a small pecan hollow form, my first in pecan. Looked great but when I applied the oil I noticed fine scathes. Is this what you mean by difficult and what do you do different for the pecan? ThanksThe symposium this past weekend was great, but I was definitely pining to get back on the lathe. Working on a fairly small, very curly Pecan calabash for a friend. I rough turned this quite a while ago and am now finish turning. Pecan is quite hard, and kind of a pain to sand, but when all said and done it is beautiful. Will finish with Danish oil and then will try a topcoat of varnish oil for the first time.

View attachment 63785

-

December 2025 Turning Challenge: Single Tree! (click here for details) -

Congratulations to Bob Henrickson, People's Choice in the November 2025 Turning Challenge (click here for details) -

Congratulations to John Dillon for "Chinquapin Oak" being selected as Turning of the Week for December 22, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What’s on your lathe?

- Thread starter Rusty Nesmith

- Start date

Hi Ted. You're spot on with what I mean about it being difficult--scratches show up in a very obvious way, especially when you have a darker piece. Despite Pecan being semi-porous, it is still fairly tight and fine grain. Yet, it is still prone to tearout and splitting. I tend to treat it like a hard exotic wood, and usually sand to at least 600g and then rub/burnish on and off the lathe with gray scrotchbrite. Off the lathe rubbing, I'll try to follow the grain as well as move randomly. This seems to take care of the fine sanding marks. Between coats of oil, I will rub repeat the same hand rubbing process. Note, there is a lot of variety in Pecan. Lighter, faster growing trees tend to be a bit more forgiving. The wood in my photo came from the lower trunk heartwood of a fairly slow-growing, very old tree. Hope that helps!Just finished a small pecan hollow form, my first in pecan. Looked great but when I applied the oil I noticed fine scathes. Is this what you mean by difficult and what do you do different for the pecan? Thanks

A new drive belt! After 20 years, the belt on my 1640 Oneway was noisy and no amount of belt dressing could put an end to the “racket”. Following the instructions from the owners manual (Oneway website), made it an easy task to complete.

I sometimes put a coat of oil on just to see scratches I’ve missed. That and the darn sun sure show them and it’s back to a lower grit.when I applied the oil I noticed fine scathes

Thanks Michael, very helpful.Hi Ted. You're spot on with what I mean about it being difficult--scratches show up in a very obvious way, especially when you have a darker piece. Despite Pecan being semi-porous, it is still fairly tight and fine grain. Yet, it is still prone to tearout and splitting. I tend to treat it like a hard exotic wood, and usually sand to at least 600g and then rub/burnish on and off the lathe with gray scrotchbrite. Off the lathe rubbing, I'll try to follow the grain as well as move randomly. This seems to take care of the fine sanding marks. Between coats of oil, I will rub repeat the same hand rubbing process. Note, there is a lot of variety in Pecan. Lighter, faster growing trees tend to be a bit more forgiving. The wood in my photo came from the lower trunk heartwood of a fairly slow-growing, very old tree. Hope that helps!

Thanks Alan.I sometimes put a coat of oil on just to see scratches I’ve missed. That and the darn sun sure show them and it’s back to a lower grit.

Odie

Panning for Montana gold, with Betsy, the mule!

I just wasn't happy with the quality of the grooves on the top of this Amboyna burl bowl. Although, it stuck out like a sore thumb every time I looked at it, I kept thinking nobody would notice the flaw, but that saying, "If you think it's good enough, it probably isn't" kept bugging me......so, I put it back on the lathe last night and re-did the top surface. I was afraid I'd ruin a very expensive piece of wood.....but, all turned out well!

Before pic: --------------------------------------------------- After pic:

-o-

Before pic: --------------------------------------------------- After pic:

-o-

Last edited:

Odie

Panning for Montana gold, with Betsy, the mule!

Jim McLain

Artist

Much better Odie, I think there were too many lines and it was detracting from the figure and color on the rim....I just wasn't happy with the quality of the grooves on the top of this Amboyna burl bowl. Although, it stuck out like a sore thumb every time I looked at it, I kept thinking nobody would notice the flaw, but that saying, "If you think it's good enough, it probably isn't" kept bugging me......so, I put it back on the lathe last night and re-did the top surface. I was afraid I'd ruin a very expensive piece of wood.....but, all turned out well!

Before pic: --------------------------------------------------- After pic:

View attachment 63813 View attachment 63814

-o-

But boy that red color isFinished up an Australian Red River Gum burl bowl last night, too.

Man, this wood really tears up your sandpaper and discs!

-o-

View attachment 63815 View attachment 63816

- Joined

- Nov 27, 2021

- Messages

- 241

- Likes

- 1,000

- Location

- Silver Spring, MD

- Website

- www.transpirationturning.com

Concave, radius is about 15”, so a slight dish to the piece.Hey Pat, is the profile flat or slightly concave? Looked at your previous Picts and couldn't decide.

Last edited:

I just finished hollowing a piece of Monkeypod (suar) with some nice spalting and a very cool bark inclusion. Still pondering the finish because the other side has a lot of gray stain. I may try a wash of wood dye to blend it without obscuring the spalting.

Attachments

- Joined

- Feb 6, 2010

- Messages

- 3,463

- Likes

- 2,533

- Location

- Brandon, MS

- Website

- threeringswoodshop.square.site

Odie

Panning for Montana gold, with Betsy, the mule!

Paper Birch from a former club member whose trees died in the last drought and he donated the wood to the club. Had some spalting, but it looks better on a few pieces that I have not gotten around to turning yet. Natural edge on the rim although the bark fell off while drying. The spout feature was nature doing its thing.

Jay

Jay

Well I was able to make this into two pieces so back the table saw to cut another ring or two to safe the bottom pieceWorking on a dip bowl to go along with the chips

Odie can I ask what media do you use on you glue block?Couple of projects.. Natural edge Mesquite bowl and Ambrosia Maple vaseView attachment 50142View attachment 50143

Small Cherry bowl from part of a crotch. The sapwood side was rotted/spalted but it made for an interesting look. Yorkshire grit followed by Myland's.

My LaserPecker does this to me once in a while. Despite my sending it a new image, and that new image showing up correctly in the app, it sometimes uses the previous image I uploaded. This burning is sort of deep so I really don't want to sand off the logo and re-burn it.

My LaserPecker does this to me once in a while. Despite my sending it a new image, and that new image showing up correctly in the app, it sometimes uses the previous image I uploaded. This burning is sort of deep so I really don't want to sand off the logo and re-burn it.

Cheese & cracker plate with cheese knife and cheese fork. Going to make two more, this one was practice since it had a crack. Had to hand inlet the pewa since the router and template wouldn't fit into the curve. Filled the knot voids with epoxy and coffee grounds.