I'm interested in buying an indexing plate. I've researched past threads on this and have a couple questions. From what I've found Alisam and Chefware are the only two brands I can find. For 1 1/4" spindle Alisam offers a 10" aluminum wheel that has 144, 120, 98, and 16 holes. Chefware offers a 12" steel plate for 1 1/4" spindle with 192, 144, 120, 90, 88, and 56 holes. How important is it to have the extra holes offered on the Chefware plate? My lathe is 15" swing and I'm afraid the 12" wheel will get in the way of the router. My main interest is using a router to do fluting on bowls and possibly spindles. I have made a plate to mount in the banjo and the brackets to allow the trim router to move about the base. I also ordered a 3" spindle extender to move the chuck away from the headstock to allow more room for the router to move about. Thanks in advance.

-

We just finished moving the forums to a new hosting server. It looks like everything is functioning correctly but if you find a problem please report it in the Forum Technical Support Forum (click here) or email us at forum_moderator AT aawforum.org. Thanks! -

Beware of Counterfeit Woodturning Tools (click here for details) -

Johnathan Silwones is starting a new AAW chapter, Southern Alleghenies Woodturners, in Johnstown, PA. (click here for details) -

Congratulations to Dave Roberts for "2 Hats" being selected as Turning of the Week for April 22, 2024 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Indexing Plate

- Thread starter Vincent Vogel

- Start date

I have both the Alisam and Chefware Kits wheels ... you cannot go wrong with either one. They are both nicely machined and accurate. I use the Chefware Kits wheel on my PM 3520C, and the Alisam on my PM 2014.

The additional rings of holes on the Chefware Kits wheel may come in handy for some, but I have never used them.

If I need a different number or combination of holes, I can make a custom wheel on my laser (I just made a wheel with 50 holes for a 25 segment open segment project I am planning).

The additional rings of holes on the Chefware Kits wheel may come in handy for some, but I have never used them.

If I need a different number or combination of holes, I can make a custom wheel on my laser (I just made a wheel with 50 holes for a 25 segment open segment project I am planning).

Contact Doug Schneiter for yet a third option.

I have the Chefware kit and like it, but use it primarily for basket illusion pieces. I wish Doug had his available before I bought the Chefware one.

I have the Chefware kit and like it, but use it primarily for basket illusion pieces. I wish Doug had his available before I bought the Chefware one.

- Joined

- Apr 27, 2004

- Messages

- 8,642

- Likes

- 4,982

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

How important is it to have the extra holes offered on the Chefware plate?

For fluting and spirals you need to think about how many flutes and spirals.

I have done spiral patterns for which I prefer odd numbers of flutes like 5, 7, 11 to eliminate symmetry

Star fish have 5 points.

Looking at the factors is the way I compare wheels. Maybe this will help you maybe not.

We don’t all think about geometry and numbers the same

I bought a disc for use with a fluting jig, it only has 60, 48, 36 and 14 holes. It’s 250mm (10”) diameter.

There is also the Paul Howard version, which only comes bored for M33 (but you could make an insert for whatever your spindle is).I think there is only one North American vendor, in BC. https://blackforestwood.com/products/paul-howard-index-system?_pos=1&_sid=20e384d69&_ss=r

There is also a very interesting fluting jig from him; I saw both of these in a video from Steve Jones (woodturner21) https://blackforestwood.com/product...30827&pr_ref_pid=6946497200171&pr_seq=uniform

There is also a very interesting fluting jig from him; I saw both of these in a video from Steve Jones (woodturner21) https://blackforestwood.com/product...30827&pr_ref_pid=6946497200171&pr_seq=uniform

Last edited:

That’s the disc I bought. I didn’t like the setting pin though so I made my own. I also drilled a *second set of holes on the 36 ring of holes giving me 72, 60, 48, 36 & 14.There is also the Paul Howard version, which only comes bored for M33 (but you could make an insert for whatever your spindle is).I think there is only one North American vendor, in BC. https://blackforestwood.com/products/paul-howard-index-system?_pos=1&_sid=20e384d69&_ss=r

There is also a very interesting fluting jig from him; I saw both of these in a video from Steve Jones (woodturner21) https://blackforestwood.com/product...30827&pr_ref_pid=6946497200171&pr_seq=uniform

*The second set of holes are a different size to differentiate if needed. The indexing pin is dual size to accommodate.

I also made my own version of the fluting jig.

Last edited:

A fourth option is a "spin index fixture", which has 360 positions so any number of combinations that will divide into 360 and result in a whole number is possible. Example 12 stops would be every 30 degrees as in 0, 30, 60, 90, etcetera however 360 / 16 = 22.5 so 16 would not be settable.

If you do a search for "Spin Index Fixture" you would get an idea what is available. The method I used to link to my headstock was to mount the fixture on the top of the lathe and connect to the spindle with a chain loop. If you are just going to be fluting many of the lathes based on Chinese castings have limited indexing built in.

If you do a search for "Spin Index Fixture" you would get an idea what is available. The method I used to link to my headstock was to mount the fixture on the top of the lathe and connect to the spindle with a chain loop. If you are just going to be fluting many of the lathes based on Chinese castings have limited indexing built in.

john lucas

AAW Forum Expert

The chefwarekits outer 2crings are the mist common divisions used fir basket illusion platters and vessels.

I find that getting jigs with options that may not be useful to where my brain is now, are always available for later on where my brain might go to!! Don’t limit your possibilities!

I’ve got a Spin Indexer for use on my milling machine. There’s no way though that I can mount it on my lathe head. I could though use it on a compound table I’ve recently bought for my lathe. Cutters would then need to go in the headstock spindle.A fourth option is a "spin index fixture", which has 360 positions so any number of combinations that will divide into 360 and result in a whole number is possible. Example 12 stops would be every 30 degrees as in 0, 30, 60, 90, etcetera however 360 / 16 = 22.5 so 16 would not be settable.

View attachment 62062

If you do a search for "Spin Index Fixture" you would get an idea what is available. The method I used to link to my headstock was to mount the fixture on the top of the lathe and connect to the spindle with a chain loop. If you are just going to be fluting many of the lathes based on Chinese castings have limited indexing built in.

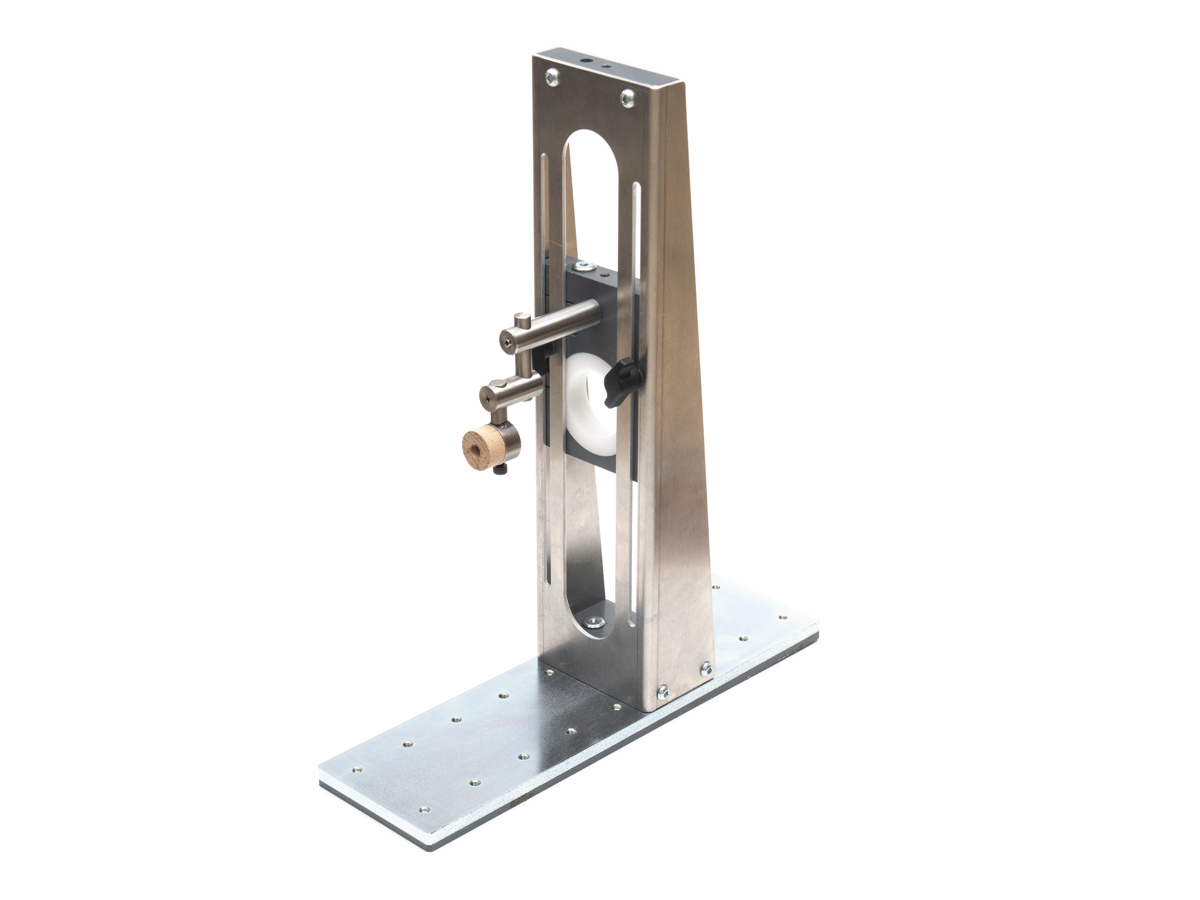

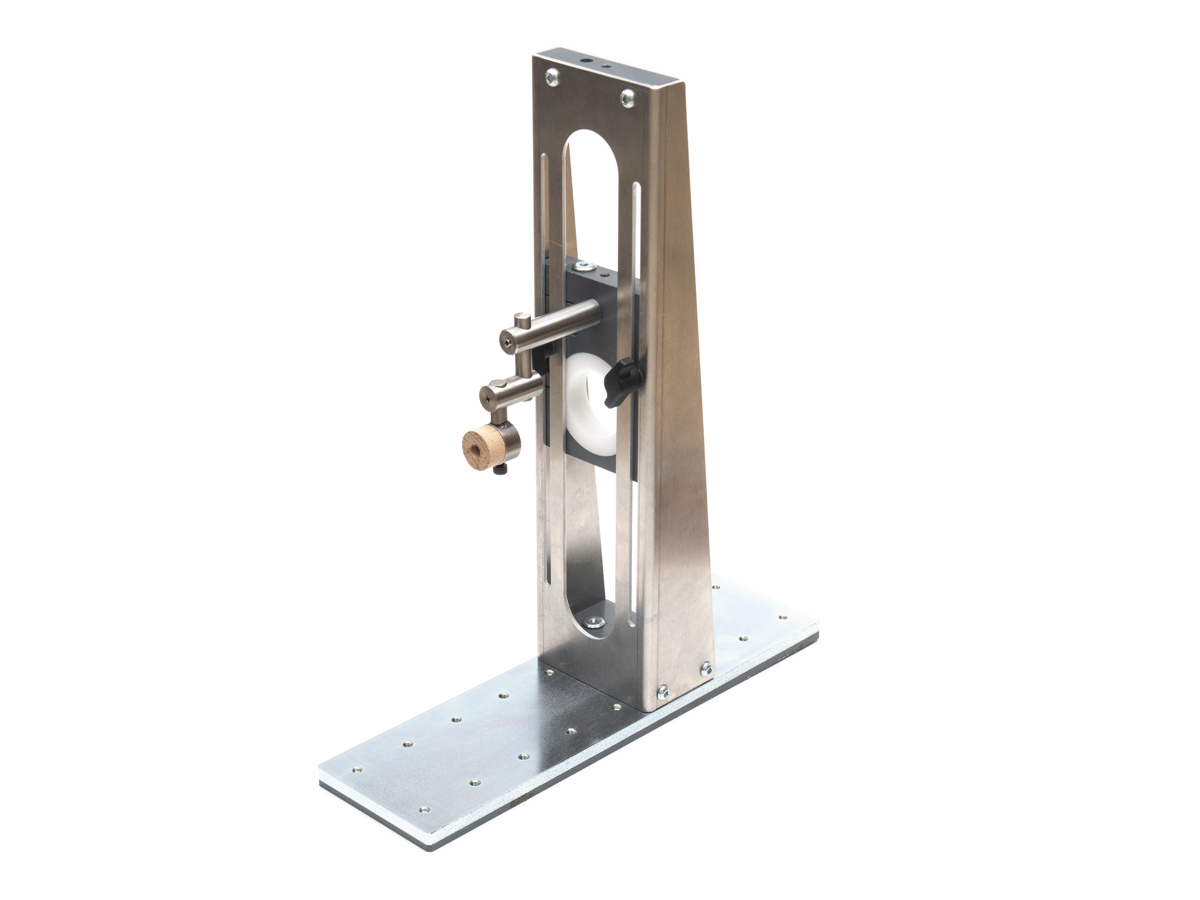

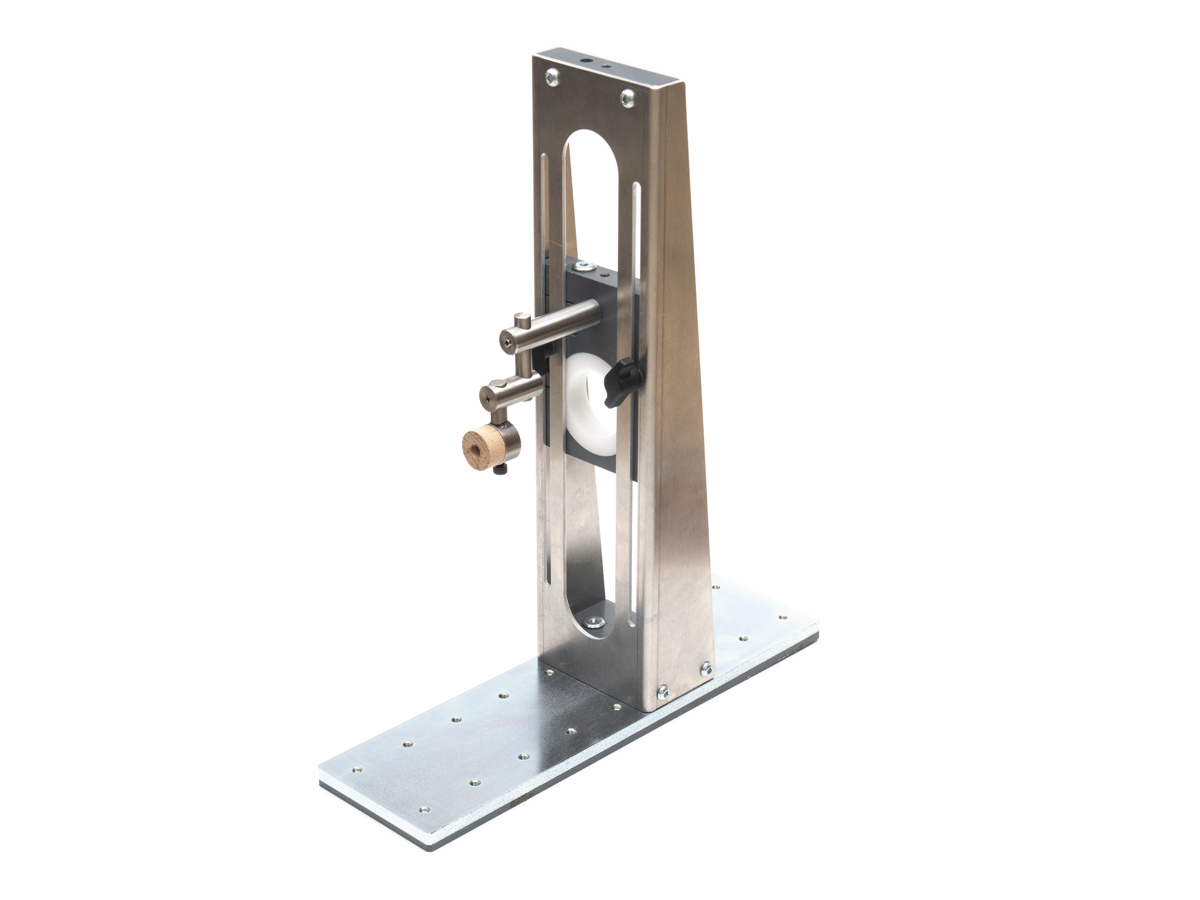

That’s a serious trimmer holder. Can you tell me how the trimmer is secured to the holder? The whole rig is STRUCTURAL!

Thomas, was that comment for myself or Don?That’s a serious trimmer holder. Can you tell me how the trimmer is secured to the holder? The whole rig is STRUCTURAL!

Thanks for all the replies. After reading all the comments I made two cardboard mockups of index plates, a 10" and a 12" I realized that going with the 10" only saves 1" of space on the side I'm working on. So I think I will wait until my spindle extender comes and get the 12". I also had to move the toolpost closer to the edge of the router jig since my banjo isn't as long as one for a larger lathe.

john lucas

AAW Forum Expert

For those interested here is a link to my router demo. I have changed a few things since then but this covers the basics.

View: https://youtu.be/yu0cJeKhqLA?si=6zrWl4pMxAECq4Zr

Here's another thought. I was looking around on the net last night and saw where a guy was doing fluting on bowls. The way he did it was turn the outside of the bowl to shape and put a tenon on the top of the bowl then turn the bowl around so the bottom of the bowl faces the tailstock and do the fluting before the interior was hollowed out. Then turn the inside of the bowl when done with the fluting on outside. This would eliminate most clearance problems with the index plate, etc. Any of you people that have done fluting on bowls how do you do it?

- Joined

- Apr 27, 2004

- Messages

- 8,642

- Likes

- 4,982

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

The fluting I’ve done is an Al Stirt technique.Any of you people that have done fluting on bowls how do you do it?

Flutes are carved clamping the bowl to a board with a 1x2 across the bottom. Long bolts and wing nuts hold the 1x2 against the bak board.

Carving is done with gouges. I use an arbotech. You get a less machine look and a feel I like

I did a 1/2 dozen or so before I moved on to other forms.

The stand and a small walnut bowl about 9” diameter .

. ……..

. ……..

Nice bowl!

That’s a serious trimmer holder. Can you tell me how the trimmer is secured to the holder? The whole rig is STRUCTURAL!A fourth option is a "spin index fixture", which has 360 positions so any number of combinations that will divide into 360 and result in a whole number is possible. Example 12 stops would be every 30 degrees as in 0, 30, 60, 90, etcetera however 360 / 16 = 22.5 so 16 would not be settable.

View attachment 62062

If you do a search for "Spin Index Fixture" you would get an idea what is available. The method I used to link to my headstock was to mount the fixture on the top of the lathe and connect to the spindle with a chain loop. If you are just going to be fluting many of the lathes based on Chinese castings have limited indexing built in.

That’s a serious trimmer holder. Can you tell me how the trimmer is secured to the holder? The whole rig is STRUCTURAL!

Here is a better view the clamp for the trimmer is made from a 2" pipe coupling, which I 1st trued up the outside then mounted it in the 4 jaw chuck to bore it to the diameter of the trimmer. The top of the mount has a cut in it to grip the trimmer and all it takes for a firm hold is to tighten the hose clamp. the rest of it is visible in the picture (don't look to close at the welds they ani't pretty but they hold). The cross slide is an old Delta accessory that gives a good steady feed plus the angle of travel can be set.

Thank you, Don. That answers my question. I recognized the pipe coupling but didn’t grasp the scale until you zoomed out a little. I’m working on a similar rig but for my little dremel and you have me going in the right direction. You must have a really good junk pile. Thanks again.

Very nice design and slick fab. You’ve done a great job securing the motor and really nice pictures. More ideas for my little Dremel project! Thanks againA couple of pictures, should be self explanatory but ask away if you need any more. I made the motor mount out of 5/8” thick alloy bar.

View attachment 62298

View attachment 62300

Most of my indexing is done with 8 or 12 positions, very seldom higher number of indexing. Shown are some test pieces. All pieces were done with the same cutter.

First picture is basic 12 position indexing, flutes with radius proportional to the part diameter. As the diameter decreases the flute radius decreases in proportion. The flutes have a slight twist down the length of the piece which is not apparent in the picture.

Next picture shows 8 position indexing. Again flutes are in proportion to diameter (visible in top two pieces). Lower right, same idea except the rate of twist increases . Two pieces to lower left are 4 position indexing. The two dark wood (ebony) are much higher index numbers, probably 36 positions.

First picture is basic 12 position indexing, flutes with radius proportional to the part diameter. As the diameter decreases the flute radius decreases in proportion. The flutes have a slight twist down the length of the piece which is not apparent in the picture.

Next picture shows 8 position indexing. Again flutes are in proportion to diameter (visible in top two pieces). Lower right, same idea except the rate of twist increases . Two pieces to lower left are 4 position indexing. The two dark wood (ebony) are much higher index numbers, probably 36 positions.

Last edited:

What type of cutters are you using Doug?

Same type cutter used with threading jigs usually with a larger diameter.What type of cutters are you using Doug?

And where ever possible using a climb cut. Regarding climb cutting, I've noticed a good many demonstrators of threading jigs don't use climb cuts. Climb cuts can make a significant difference in cut quality.

You are a very talented metal worker. Do you sell this type of holder? The only problem is that I live in Australia, but I am happy to pay all of your postage costs. CheersA couple of pictures, should be self explanatory but ask away if you need any more. I made the motor mount out of 5/8” thick alloy bar.

View attachment 62298

View attachment 62300

Sadly it takes me too long to make stuff like this to cover my costs. That would also be assuming I have the time which I don’t at present. I will help in any way I can though to help you build one. The materials shouldn’t be difficult to source locally except perhaps the alloy channel.You are a very talented metal worker. Do you sell this type of holder? The only problem is that I live in Australia, but I am happy to pay all of your postage costs. Cheers

I started with just a flywheel ring gear from an old truck. (180 teeth for under $30) I did finally buy the Chefware indexing wheel and made my own stop pin. (just a bolt turned to a point in a stiff strip of wood) A smooth wheel with holses is safer than a bunch of jagged teeth and it also gives a wider variety of flutes/spacing.

For the router part, I just made wood block that fits on the side of the router and a small table that goes into my banjo. Simple, cheap, and effective.

For the router part, I just made wood block that fits on the side of the router and a small table that goes into my banjo. Simple, cheap, and effective.

Thanks for your reply Bill. Like you, my time is precious. I will attempt this sort of build, but if I can purchase one, I will. Thanks again.Sadly it takes me too long to make stuff like this to cover my costs. That would also be assuming I have the time which I don’t at present. I will help in any way I can though to help you build one. The materials shouldn’t be difficult to source locally except perhaps the alloy channel.

There’s this one:

hopewoodturning.co.uk

hopewoodturning.co.uk

Paul Howard fluting jig

Paul Howard's fluting jig. Height-adjustable fluting jig for processing surfaces in long and cross timber. Due to the numerous…

Router fluting jigs need a large base so they don't tip in usage. The one linked to in post #46 has too small a base. It has holes in the base that I assume are to screw it to large base.

Variations of these type router holders are frequently used to "turn" designs based on tracing a profile template of the part to be turned. Set it up correctly spindle turning is easy, Shallow bowls too.

Variations of these type router holders are frequently used to "turn" designs based on tracing a profile template of the part to be turned. Set it up correctly spindle turning is easy, Shallow bowls too.

This is the Paul Howard Jig in action. There are quite a few other YouTube videos of this jig.

Well I finally got my fluting jig ready to use. I fluted this bowl, it's a roughed out bowl that's dry I figured I would try it out on this then turn it after I'm done playing around and put permenant flutes on it after it's twice turned. It took me a while to figure out how to use the index plate and how many flutes will fit. I found a you tube by William Lancaster that had the formula to figure this out. I'm still going to try to turn the bowl around and put the foot towards the tailstock. I need to come up with a better holder for the pin for the index plate.

Attachments

There’s this one:

Paul Howard fluting jig

Paul Howard's fluting jig. Height-adjustable fluting jig for processing surfaces in long and cross timber. Due to the numerous…hopewoodturning.co.uk

Thanks Doug. I have just invested in a couple of items from Hope Woodturning. I appreciate the input which come from experienced members like you. Cheers, Matt FawknerRouter fluting jigs need a large base so they don't tip in usage. The one linked to in post #46 has too small a base. It has holes in the base that I assume are to screw it to large base.

Variations of these type router holders are frequently used to "turn" designs based on tracing a profile template of the part to be turned. Set it up correctly spindle turning is easy, Shallow bowls too.