odie

TOTW Team

- Joined

- Dec 22, 2006

- Messages

- 7,116

- Likes

- 9,823

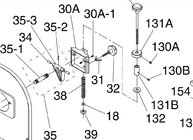

Odie, I think that is a fairly common part if you're talking about the cast aluminum-zinc alloy that adjusts the upper wheel tilt and tension. I bought a Delta clone about 35 years ago and that part broke when the saw was only 5 or 6 years old. The aftermarket replacement was much higher quality and is still in perfect shape.

Bill.....Yes, I think you are speaking of the same part that broke. I'm not aware of a replacement part.....where would I look to find one?

I'll call Grizzly in the morning to check.

In the mean time, I've been comparing bandsaws all day here. I think if I had to buy another band saw, the Grizzly G0817 with the foot brake, is what I'll probably settle on:

14" Super HD 2 HP Resaw Bandsaw w/ Foot Brake

<h1>G0817 14" Super HD 2 HP Resaw Bandsaw w/ Foot Brake</h1> <h2>This award-winning heavy-duty bandsaw features an industry-leading 14" resaw capacity!</h2> <p>The G0817 14" Super HD 2 HP Resaw Bandsaw was awarded Top Tool by <em>WOOD Magazine</em> for its performance and combination of features...