I'd love to learn about different kinds of finishes and why people use them. My go-to is Hampshire Sheen Gloss Wax because of its ease and food-safety rating, but I'd like to branch out into other finishes that last longer.

-

December 2025 Turning Challenge: Single Tree! (click here for details) -

Congratulations to Bob Henrickson, People's Choice in the November 2025 Turning Challenge (click here for details) -

Congratulations to Guillaume Fontaine for "Old Tea Pot" being selected as Turning of the Week for December 15, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What is your favorite finish and why?

- Thread starter Maggie Shapiro

- Start date

I'm personally a big fan of BLO/wax finish. I haven't turned yet, but uses this finish on many flatwork pieces in the past. While not a durable finish, it can be readily re-touched and offers such a warm natural glow. If it's good enough for Richard Raffan it's good enough for me.

Like you I'll be interested in others responses to this topic. So much to learn, so many possibilities. Hopefully you find what you are looking for in this thread.

Gregory

Like you I'll be interested in others responses to this topic. So much to learn, so many possibilities. Hopefully you find what you are looking for in this thread.

Gregory

I use a couple and depends on what the piece is. Danish Oil of my own mix 40-20-20, 40 poly urethane satin, but gloss is fine, 20 BLO and thinners of your choice, 2-3 coats and let dry off even if it takes a few days and then buff.

Gallery items I use a W.O.P. poly although its no longer available down here, so its my version of it. Always satin finish over the above DO. Allow it to dry and harden, then buff with 100 layer cotton or linen buff to the required amount of shine. The avatar is done this way Poly Urethane on Ebony.

Gallery items I use a W.O.P. poly although its no longer available down here, so its my version of it. Always satin finish over the above DO. Allow it to dry and harden, then buff with 100 layer cotton or linen buff to the required amount of shine. The avatar is done this way Poly Urethane on Ebony.

For bowls I’ve settled on Tried and True Danish oil. One, sometimes two coats and buffed after a few days. For Basket illusion it’s one coat of Wipe on Poly and sometimes a few coats of lacquer over that.

Long time furniture maker...novice turner:

I've used many finishes for furniture and I've settled on Rubio monocoat for its warm and touchable surface.

For turning I like any neutral penetrating oil with wax on top.

For what it's worth, I've never tried a hard wax oil on a turned project...maybe I should.

I've used many finishes for furniture and I've settled on Rubio monocoat for its warm and touchable surface.

For turning I like any neutral penetrating oil with wax on top.

For what it's worth, I've never tried a hard wax oil on a turned project...maybe I should.

For most bowls I use Tried and True Original or Tried and True Danish Oil. Small display pieces I use Myland's High Build Friction Polish or shellac.

Thank you so much Gregory! I’ve seen a lot of turners using BLO but haven’t tried it myself yet.I'm personally a big fan of BLO/wax finish. I haven't turned yet, but uses this finish on many flatwork pieces in the past. While not a durable finish, it can be readily re-touched and offers such a warm natural glow. If it's good enough for Richard Raffan it's good enough for me.

Like you I'll be interested in others responses to this topic. So much to learn, so many possibilities. Hopefully you find what you are looking for in this thread.

Gregory

Fabulous thank you, I haven’t used Danish oil or Myland’s friction polish but I’ve used Myland’s cellulose sanding sealer and it’s quality stuff.For most bowls I use Tried and True Original or Tried and True Danish Oil. Small display pieces I use Myland's High Build Friction Polish or shellac.

Thanks Aron! Is Rubio like Osmo? I’ve used Osmo Polyc Oil on many turned projects and love how it turns out. Only downside is if you have lots of nooks and crannies it can build up in there and dry white, so I pretty much only use it on smooth pieces. It’s great to apply and buff on when on the lathe.Long time furniture maker...novice turner:

I've used many finishes for furniture and I've settled on Rubio monocoat for its warm and touchable surface.

For turning I like any neutral penetrating oil with wax on top.

For what it's worth, I've never tried a hard wax oil on a turned project...maybe I should.

Thanks Mark! I’m going to be attempting my first-ever basket illusion very soon (have the bottom beads done but was waiting on an indexing kit) and I was wondering what finish to use on it. My understanding is finish can sometimes make the coloring of the beads run, is that right? I guess it depends on what you use to color themFor bowls I’ve settled on Tried and True Danish oil. One, sometimes two coats and buffed after a few days. For Basket illusion it’s one coat of Wipe on Poly and sometimes a few coats of lacquer over that.

Does Danish oil hold up over time or does it need re-polishing down the road?

Thanks so much Hughie, this is very informative! What brand of polyurethane do you prefer? And what thinners do you use on the BLO? I have used a Minwax water-based clear wipe-on polycrylic a couple times and I really like it, it is truly clear if you just want to highlight the grain. But I don’t love that it raises the grain so I have to sand it back between coats. BTW I love the piece in your avatar, have been thinking of trying this but in a subtle spiral pattern around a vessel. What is this type of detail work called? Is it carving and sanding? Do you use an indexing wheel to mark where the lines go? Thanks!I use a couple and depends on what the piece is. Danish Oil of my own mix 40-20-20, 40 poly urethane satin, but gloss is fine, 20 BLO and thinners of your choice, 2-3 coats and let dry off even if it takes a few days and then buff.

Gallery items I use a W.O.P. poly although its no longer available down here, so its my version of it. Always satin finish over the above DO. Allow it to dry and harden, then buff with 100 layer cotton or linen buff to the required amount of shine. The avatar is done this way Poly Urethane on Ebony.

I haven’t used osmo, but my understanding is they are quite similar. You can google a comparison of those that furniture makers use [Blacktail studio or wood whisperer are places to start].Thanks Aron! Is Rubio like Osmo? I’ve used Osmo Polyc Oil on many turned projects and love how it turns out. Only downside is if you have lots of nooks and crannies it can build up in there and dry white, so I pretty much only use it on smooth pieces. It’s great to apply and buff on when on the lathe.

I also finish a lot of oak or black walnut so my experience is limited to this woods.

I’ve attached a simple oak stool with Rubio. I think the legs were about the first thing I’ve turned on the lathe a couple of months ago.

Attachments

- Joined

- Feb 28, 2021

- Messages

- 1,775

- Likes

- 1,587

- Location

- Roulette, PA

- Website

- www.reallyruralwoodworks.com

Tried & True brand Danish oil is just pure Polymerized Linseed Oil (It isn't BLO like you buy in the can with tons of chemical driers and stuff added) It is pretty expensive, however so little is needed for each coat, it'll last a long time. (Carefully read their use instructions on their website if you get a can of it - your results will be much better when you fully understand the ideas - when they say a "thin coat" that means just enough to wet the wood and if you wipe a finger over it, it feels oily - only add more if it feels dry after soaking-in time - My first use I made the mistake of literally flooding so there was shiny film before wiping that off - It kept wicking out more oil when set in a warmer/dryer place than the shop for several months until it finally fully cured.) I am also a fan of the other (Varnish oil and Original) Tried & True products and still have some of my pint can of Original that I bought 4 years ago, even though I used it a LOT.Thanks Mark! I’m going to be attempting my first-ever basket illusion very soon (have the bottom beads done but was waiting on an indexing kit) and I was wondering what finish to use on it. My understanding is finish can sometimes make the coloring of the beads run, is that right? I guess it depends on what you use to color them

Does Danish oil hold up over time or does it need re-polishing down the road?

Edited to add: Main reason I was posting this was the mentions of natural food safe finishes - Tried and True, like any other penetrating oil based finish, (even commercial ones) does eventually need re-polishing/touch-up/maintenance down the road.. not so much by the nature of the oils, but because wood does absorb and release moisture, wood moves, period. Benefits to the pure linseed oils (and Pure Tung Oils, not the glitzy mis-named name brand stuff you find at hardware stores) are mainly when wanting food safe finishes for things like utensils, bowls, cutting boards, and other kitchen/ food contact items where a film finish (like polyurethane, lacquer, etc) can chip and scratch and leave microscopic pieces of finish in your food (in addition to scratched film finish simply looks ugly!)

As for coloring before adding linseed oil finish, you can actually color the oil (linseed oil and tung oil - they actually market linseed oil paints, which was pretty much THE paint way back before the industrial revolution or so...) , if you are using the right kind of dyes , however pretty much ANY liquid finish is going to run and follow the grain of wood unless you can interrupt the grain (typically a cut or burned like 1/64" deep or so) - If your concern is your color running after coloring beading, probably should first figure out how much of an interrupt cut/burn you need in your particular wood. (Some woods need deeper cuts due to coarse grain, while other woods can be just fine with not much more than a fingernail scratch, to stop bleeding which is just coloring following the grain)

Last edited:

Wow thank you so much for all the info! I will look up Tried & True and some of the pure linseed/tung oils.

As far as the basket illusion finish, I did read that some folks don't even use finish. What do you think about that?

As far as the basket illusion finish, I did read that some folks don't even use finish. What do you think about that?

Beautiful work! Thank you for sharing!I haven’t used osmo, but my understanding is they are quite similar. You can google a comparison of those that furniture makers use [Blacktail studio or wood whisperer are places to start].

I also finish a lot of oak or black walnut so my experience is limited to this woods.

I’ve attached a simple oak stool with Rubio. I think the legs were about the first thing I’ve turned on the lathe a couple of months ago.

I think it all depends on personal preference. I like OB shine juice on some things (1 part shellac, 1 part linseed oil and 1 part denatured alcohol and applied with friction). My main finish is Waterlox gloss but a lot of ppl don't like the dry time. I really like a shiny hard finish tho so it's worth it. I haven't used Osmo but I hear good things about it.

For my daily use bowls, I use the walnut oil from the Doctor's Woodshop. Mahoney's is similar, but the Doctor is from Oregon.... For my flat work and other heavy use products, I am coming to prefer the Rubio monocote. I do like it better than the Osmo. I know Osmo is used a lot on floors, and both Monocote and Osmo are low odor products, but I like the end result finish from Rubio better. I have yet to try the ceramic top coat from Black Tail Studio. I need to get some first.... I know it comes from the auto industry, and the Black Tail Studio guy appears to use it on everything like table saw tops.... There is always some thing new to try!

robo hippy

robo hippy

I think it all depends on personal preference.

The finish I use or don't might depend on things:

- the wood - ebony, cocobolo, basswood, hickory, mesquite, cherry, osage orange?

- the figure - oils can bring out the figure, chatoyance

- the intended use - for display on a shelf, eating salad, serving cookies, feeding the dog, holding coins?

- will color be added, finish over the color?

- what it will be exposed to - the elements outdoors, washing/rinsing at the sink, alcohol? (shellac can dissolve in alcohol)

- fine or coarse grain, and how smooth I want the final surface.

- how much of a rush - some great drying oil finishes can take days or weeks to apply.

- is the wood bone dry or not?

- what I feel like at the time.

Certain combinations I have learned NOT to use. For example, using "danish" oil on cocobolo can cause it to turn very dark, nearly black, in a relatively short time. High gloss finish on ebony can make it look like plastic. Some finishes can make otherwise pure white wood look yellow

It's a big and confusing topic. To make it worse, there are lots of finshes sold that are basically the same as others of different brands.I'd love to learn about different kinds of finishes and why people use them. My go-to is Hampshire Sheen Gloss Wax because of its ease and food-safety rating, but I'd like to branch out into other finishes that last longer.

To get a scattering of advice without context can be even more confusing.

My recommendation is to pick one and try it a few times, then try another. Take notes. Learn what you like best.

To explain the in detail what and why people use could fill a book.

For a good introduction, maybe some existing books would help. Some on my shelves are:

Great Wood Finishes by Jeff Jewitt

Understanding Wood Finishing by Bob Flexner

Traditional 19th Century Finishes (Shellac, Linseed oil, paint) by Stephen Shepherd

plus specific recommendations tucked inside the books of dozens of great woodturning authors.

JKJ

Great thank you!I think it all depends on personal preference. I like OB shine juice on some things (1 part shellac, 1 part linseed oil and 1 part denatured alcohol and applied with friction). My main finish is Waterlox gloss but a lot of ppl don't like the dry time. I really like a shiny hard finish tho so it's worth it. I haven't used Osmo but I hear good things about it.

Ok thanks for the tip! I'll look into the Doctor's Woodshop oil. I've heard good things about walnut oil but haven't tried it yet. Ditto Rubio Monocote - I'll have to check it out. Is it food safe?For my daily use bowls, I use the walnut oil from the Doctor's Woodshop. Mahoney's is similar, but the Doctor is from Oregon.... For my flat work and other heavy use products, I am coming to prefer the Rubio monocote. I do like it better than the Osmo. I know Osmo is used a lot on floors, and both Monocote and Osmo are low odor products, but I like the end result finish from Rubio better. I have yet to try the ceramic top coat from Black Tail Studio. I need to get some first.... I know it comes from the auto industry, and the Black Tail Studio guy appears to use it on everything like table saw tops.... There is always some thing new to try!

robo hippy

This is super helpful, thank you so much! Yes trial and error seems to be the way to go...though I'm always open to advice from folks that have been there and tried thatThe finish I use or don't might depend on things:

- the wood - ebony, cocobolo, basswood, hickory, mesquite, cherry, osage orange?

- the figure - oils can bring out the figure, chatoyance

- the intended use - for display on a shelf, eating salad, serving cookies, feeding the dog, holding coins?

- will color be added, finish over the color?

- what it will be exposed to - the elements outdoors, washing/rinsing at the sink, alcohol? (shellac can dissolve in alcohol)

- fine or coarse grain, and how smooth I want the final surface.

- how much of a rush - some great drying oil finishes can take days or weeks to apply.

- is the wood bone dry or not?

- what I feel like at the time.

Certain combinations I have learned NOT to use. For example, using "danish" oil on cocobolo can cause it to turn very dark, nearly black, in a relatively short time. High gloss finish on ebony can make it look like plastic. Some finishes can make otherwise pure white wood look yellow

It's a big and confusing topic. To make it worse, there are lots of finshes sold that are basically the same as others of different brands.

To get a scattering of advice without context can be even more confusing.

My recommendation is to pick one and try it a few times, then try another. Take notes. Learn what you like best.

To explain the in detail what and why people use could fill a book.

For a good introduction, maybe some existing books would help. Some on my shelves are:

Great Wood Finishes by Jeff Jewitt

Understanding Wood Finishing by Bob Flexner

Traditional 19th Century Finishes (Shellac, Linseed oil, paint) by Stephen Shepherd

plus specific recommendations tucked inside the books of dozens of great woodturning authors.

JKJ

Tom Gall

TOTW Team

Choice of finish is depends on the item to be finished, as some have already stated. For a colored basket illusion piece I would assume you want a protective coat and not one that would alter the colors. I would try something like Krylon Matte finish (spray can) or some other art fixatif, and others of the same type that would work for you.Thanks Mark! I’m going to be attempting my first-ever basket illusion very soon (have the bottom beads done but was waiting on an indexing kit) and I was wondering what finish to use on it. My understanding is finish can sometimes make the coloring of the beads run, is that right? I guess it depends on what you use to color them

Does Danish oil hold up over time or does it need re-polishing down the road?

Krylon or Matte fixatif

though I'm always open to advice from folks that have been there and tried that

To get specific advice, you might describe some specifics about the wood and use and whether you like glossy, matte, etc..

The other John Jordan, the late, great, famous one, turned, carved, and textured a lot of hollow forms. He told me he sprayed almost everything with matte acrylic in a rattle can from the hardware store. Has pieces in museums and in the hands of collectors all over the world.

The gallery on his website seems to be down now, but this one shows a some of his pieces.

John Jordan

Website: http://www.johnjordanwoodturning.com/John_Jordan_Woodturning/Home.html Tools: http://www.johnjordanwoodturning.com/John_Jordan_Woodturning/Tools_and_More.html John Jordan is a...

www.turninggallery.org

Edit: I often use the Krylon I see Tom mentioned.

JKJ

Last edited:

Maggie as I live in Australia most if not all brands are local and so not much good too you. Just go with any quality brand you have locally it will be fine. I used to use minwax product such as Wipe on Poly and Antique OIl but a local manufacturer started a price war that Minwax couldnt win. Add to Antique Oil is getting phased out, this was one of my favourites. I still have some left and I use the 10min method devised by Keith Byrnes. Thinners, mineral turpentine and I use oil based finish's as they wont raise the grain and only go to water based to stop the darkening we get by using oil.Thanks so much Hughie, this is very informative! What brand of polyurethane do you prefer? And what thinners do you use on the BLO? I have used a Minwax water-based clear wipe-on polycrylic a couple times and I really like it, it is truly clear if you just want to highlight the grain. But I don’t love that it raises the grain so I have to sand it back between coats. BTW I love the piece in your avatar, have been thinking of trying this but in a subtle spiral pattern around a vessel. What is this type of detail work called? Is it carving and sanding? Do you use an indexing wheel to mark where the lines go? Thanks!

I use Faber Castell artist pens. I have not had a problem with the finish affecting the colors with these. Once I put on a coat of Wipe on Poly I “pat” it dry with a paper towel. I don’t wipe. Just a precaution. Spray on lacquer does not affect the colors of FC pens. If you search the forum for Basket illusion tutorial by Curt Fuller, all of your questions will be answered on basket illusion. I highly recommend it.Thanks Mark! I’m going to be attempting my first-ever basket illusion very soon (have the bottom beads done but was waiting on an indexing kit) and I was wondering what finish to use on it. My understanding is finish can sometimes make the coloring of the beads run, is that right? I guess it depends on what you use to color them

Does Danish oil hold up over time or does it need re-polishing down the road?

As for bowls, I would think over time maybe. Depends on how much use.

One word of caution, basket illusion is highly addictive. Look forward to seeing your work.

I had the opportunity to meet the other John Jordan at a Nashville club meeting a short time before his death and I saw some of his work. He was so talented. I didn't ask about the finish but I really never thought about him using rattle can. Now I feel better about using it sometimes.To get specific advice, you might describe some specifics about the wood and use and whether you like glossy, matte, etc..

The other John Jordan, the late, great, famous one, turned, carved, and textured a lot of hollow forms. He told me he sprayed almost everything with matte acrylic in a rattle can from the hardware store. Has pieces in museums and in the hands of collectors all over the world.

The gallery on his website seems to be down now, but this one shows a some of his pieces.

John Jordan

Website: http://www.johnjordanwoodturning.com/John_Jordan_Woodturning/Home.html Tools: http://www.johnjordanwoodturning.com/John_Jordan_Woodturning/Tools_and_More.html John Jordan is a...www.turninggallery.org

Edit: I often use the Krylon I see Tom mentioned.

JKJ

While I won't be doing a basket illusion any time soon if ever, this data is filled away. I can definetly see many situations where coloring will be in my future work. Is that something special about this brand or is it artist pens in general (over other pens)?I use Faber Castell artist pens. I have not had a problem with the finish affecting the colors with these.

Gregory

I had the opportunity to meet the other John Jordan at a Nashville club meeting a short time before his death and I saw some of his work.

We sure miss that guy.. I've had the pleasure of seeing him often at symposiums, attending a class taught by him and Clay Foster, and giving him a tour of my messy shop when he stayed with us after a Knoxville demo.

Living in the same state (and the same age - he was the "old" guy, one month older!) I have lots of stories of confusion over the name. One guy, thinking I was him, made and sent me a custom tool after I posted about turning tiny spheres. I told him no one ever sent me any of his money though. A woodcarver made something for me and sent it to his house! A famous turner wanted to be my Facebook friend and when I asked if she had the wrong JJ, she said, oh, yes, but I want to your facebook friend too! At my very first turning club meeting when visitors were asked to stand and give their names, a woman in front of me turned around and asked "Are you the John Jordan from Nashville?" When I said no, she said "Are you sure?" Ha!

This photo is one of my favorites, taken in Nashville outside the symposium the year it snowed:

Doug Thompson, JJ, Sir John Lucas, and 'lil ol' me.

And I'll quit with my other favorite photo, the last picture I ever took of John, in NC with Melissa and Graeme Priddle. I was making wands for people. Graeme tried to use his to influence the benefit auction in his favor but he didn't know the correct spell! Good memories...

JKJ

Is that something special about this brand or is it artist pens in general (over other pens)?

The Faber-Castell Pitt artists pens are the best I know of. I really like the black, pens, and brushes, the india ink never fades. At minimum good for signing work.

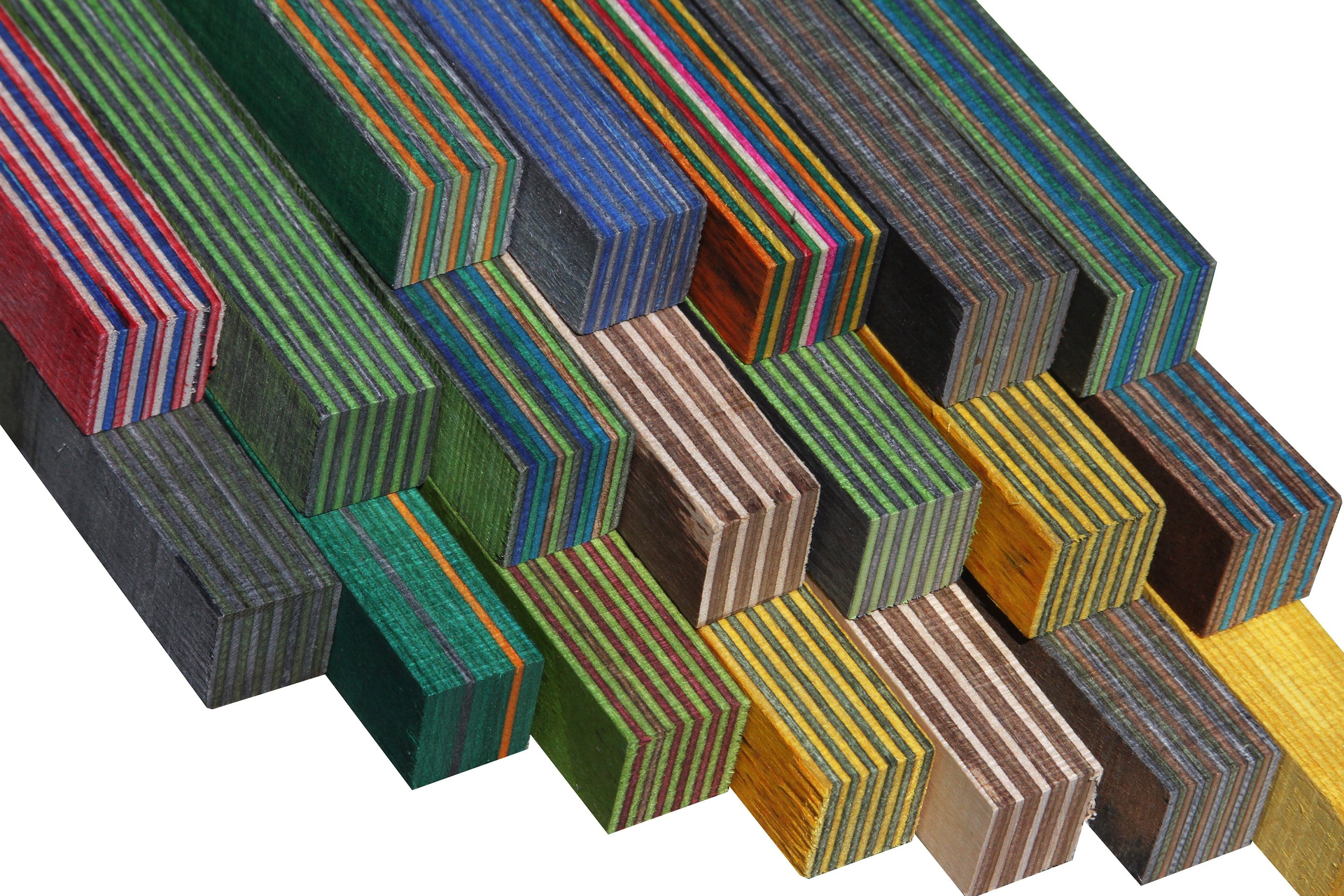

I have some sets of some colored ones too. I find the brush pens especially useful for adding color to wood, for things like these:

(Christmas tops for the kindergartners)

(But sometimes I cheat and turn from SpectraPly! Shhh, don't tell anyone...)

SpectraPly Wood

SpectraPly wood is made in the USA from veneered layers of premium yellow birch that have been brightly dyed. Spectraply blanks offer a unique turning experience that yields high quality, vibrant projects! The veneers are dyed under extreme pressure for full penetration of the dye throughout...

www.cookwoods.com

JKJ

Thanks John,

Tops is definetly one of the things I can see coloring with pens. You mention signing your work and it's something I've gone from ambivalent about to being solidly in the sign your damn work camp. Now I just have to work on a crafting signature that is legible. I've been asked numerous times if I'm a doctor based on my signature.

Gregory

Tops is definetly one of the things I can see coloring with pens. You mention signing your work and it's something I've gone from ambivalent about to being solidly in the sign your damn work camp. Now I just have to work on a crafting signature that is legible. I've been asked numerous times if I'm a doctor based on my signature.

Gregory

I've been asked numerous times if I'm a doctor based on my signature.

I just tell them the last time I checked, I still wasn't a doctor.

I've been playing around with a homemade version of shine juice: 1 part shellac, 1 part tung oil and 1 part denatured alcohol. So far I've been happy with the results. It's easy to apply and dries by the end of the day.I think it all depends on personal preference. I like OB shine juice on some things (1 part shellac, 1 part linseed oil and 1 part denatured alcohol and applied with friction). My main finish is Waterlox gloss but a lot of ppl don't like the dry time. I really like a shiny hard finish tho so it's worth it. I haven't used Osmo but I hear good things about it.

Illegible is ok too. It just needs to be something that your happy with and you can reproduce. I haven't been able to read my signature in years.Now I just have to work on a crafting signature that is legible. I've been asked numerous times if I'm a doctor based on my signature.

Gregory, some people use other brands. FC pens were recommended when I did my first one and I have no reason to switch at the present time.While I won't be doing a basket illusion any time soon if ever, this data is filled away. I can definetly see many situations where coloring will be in my future work. Is that something special about this brand or is it artist pens in general (over other pens)?

Gregory

I've kind of settled on watco danish oil. It's readily available locally where a lot of people seem to use it so it's fresh. And if it's good enough for Odie, it's good enough for me.

I've kind of settled on watco danish oil. It's readily available locally where a lot of people seem to use it so it's fresh.

I also use it more than other finishes, where appropriate. Looks good, durable, and brings out the figure. (I found out the hard way not to use it on cocobolo) Fresh is great! The local Ace hardware down the hill from me sells cheaper than the woodworking suppliers. (some people make up the equiv from equal parts of BLO or tung oil, poly, and mineral spirits) I usually apply 6 to 10 coats over a period of a week or so.

It will still go bad and set up eventually, left to it's own devices. But I treat it, and other finishes, in a way that removes the oxygen and it preserves indefinitely, as I wrote in a earlier thread. I have partially used bottles of the notoriously problematic TruOil still like new after many years.

@Maggie Shapiro , I make non-utility pieces and use Osmo Polyx Oil satin. It is one of the hard wax oil products like Rubio Monocoat. But unlike Rubio, it is a one part product. No unpleasant smell. It's easy to wipe on. It has low tack and dries quickly, so it doesn't collect a lot of dust nibs. It brings out the grain like an oil (i.e. better than polyurethane). It has an amber hue, but I think a touch less than polyurethane. Usually two coats, 12 hours apart. It dries quickly, but full cure (no smell) takes 3-4 weeks. Osmo also makes a version of Polyx Oil with more solvent called Top Coat. The Top Coat products have been tested in Europe and are food safe.

A can of Osmo is very expensive, but you use very little. A simple 12" bowl might need a few tablespoons.

A can of Osmo is very expensive, but you use very little. A simple 12" bowl might need a few tablespoons.

Jim McLain

Artist

I use a couple and depends on what the piece is. Danish Oil of my own mix 40-20-20, 40 poly urethane satin, but gloss is fine, 20 BLO and thinners of your choice, 2-3 coats and let dry off even if it takes a few days and then buff.

Gallery items I use a W.O.P. poly although its no longer available down here, so its my version of it. Always satin finish over the above DO. Allow it to dry and harden, then buff with 100 layer cotton or linen buff to the required amount of shine. The avatar is done this way Poly Urethane on Ebony.

Hughie - I’m confused. Shouldn’t the numbers add up to 100%. 40-20-20=80 what is the other 20%?

I've used MInwax Antique Oil (discontinued, RIP), Waterlox, and others, but recently have switched to Osmo Polyx Oil satin for the reasons that Mark Jundanian lists above.I'd love to learn about different kinds of finishes and why people use them. My go-to is Hampshire Sheen Gloss Wax because of its ease and food-safety rating, but I'd like to branch out into other finishes that last longer.

Most of these finishes have limited shelf life if stored in the presence of air, specifically oxygen. In other words, the finishes will start to degrade as soon as they are opened. Some like Waterlox are notorious for very short shelf life. Many others will continue to work, but may take longer to cure, or not wet out on the surface of the bowl as well as when they were new.

Stop Loss bags solve that problem and keep finishes fresh for long times, > 3 years in some cases for me. You might consider using them as you acquire finishes to test.

StopLossBags - 4 Pack | Woodcraft

Buy the - StopLossBags - 4 Pack for sale online from Woodcraft. Visit us to order online or find your local Woodcraft store today!

Stop Loss bags solve that problem

I know some who use stop loss bags effectively. I personally displace the oxygen with inert gas. (I know this is not for everyone.) Keeps everything in the original containers, no mess, the displacement takes only 10 seconds before replacing the cap.