Just curious, where did you get your clear cast acrylic? What I have is quite clear and polishes nicely.

I understand extruded acrylic is harder to polish to an optical clarity.

Also, what's an "object cell"?

I've used two methods to get glossy surfaces on cast acrylic. (I never turn extruded acrylic - it's a different animal)

Method ONE: Sand with fine then very fine sandpaper. (I always use Indasa Rhynowet paper, buy in 9x12 sheets, cut into 1"x3" strips.) After dry sanding to remove any tool marks (at a slow speed and by hand with the lathe off) with 400 grit to 1200 grit paper, I sometimes wet sand with 1200 with water. Clean well between grits with a paper towel then damp cloth to make sure all previous grit particles are removed.

Then i use one of several of the polishes on my shelf - I have several sold for plastic and some for metal, but the type doesn't seem to make any difference. I often use Simachrome since it's widely available and I've used it for years. It's advertised for polishing metals but works well on the cast acrylics.

After cleaning the plastic again with soft cloth and water, I apply the polish with a small piece of cotton "tee shirt" material, usually about 1"x3" strips, start with the lathe running (fast if I remember), then stop and polish by hand. I think I changed to fresh pieces of cloth occasionally. (I should do another one and make sure I'm remembering things correctly)

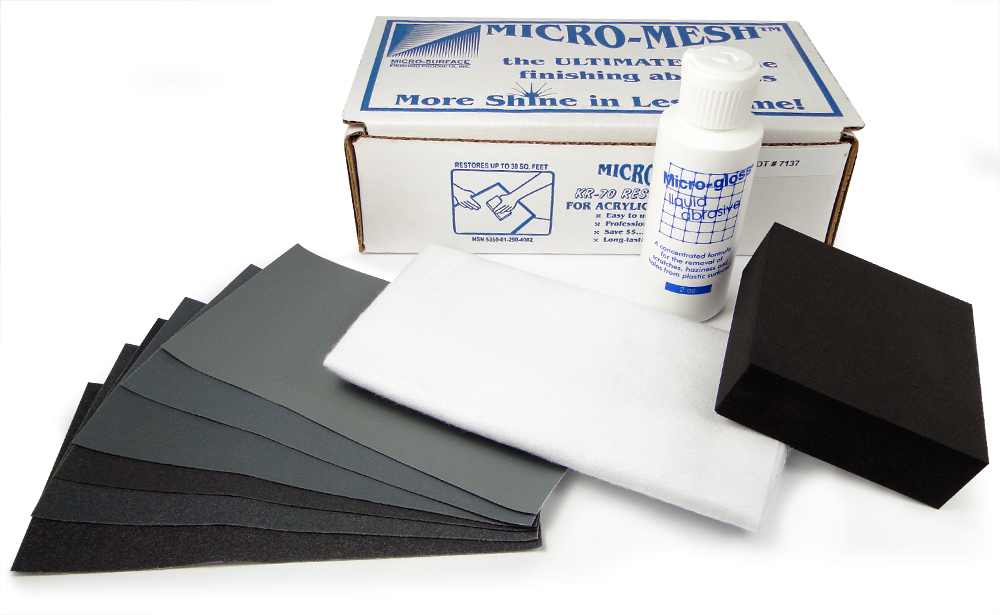

Method TWO: I can get a mirror gloss with an very old Micromesh sandpaper kit. What I have was a kit made for aircraft windows - it includes more grits and is far cheaper than the cut-down kits they sell today to woodturners. (I used it to restore our aging Cessna 172 windshield, took it from so crazed you couldn't fly towards the sun, to so clear it looked like new!) This kit has grits to 24000. I simply sanded through the grits and the result was polished. Like magic. I used a little polishing compound afterwards but it wasn't needed. I see the Micromesh kits sold now go to 6000 grit but include "micro gloss liquid abrasive" polish, whatever that is.

Micro-Mesh Acrylic Restoral Kit - 30 Square Feet Use this kit by hand to restore up to 30 square feet of acrylic. NSN#5350 01 290 4002. A favorite window restore kit with military customers.

www.aircraftspruce.com

It would be interesting to see if the new kits worked as well as the old.

One thing I haven't tried is using polish on spinning polishing wheels. These work well on wood and metals, but I suspect it would take the right wheel (quite soft and very clean) and care to prevent overheating which might soften the surface.

BTW, I've also used extremely fine diamond paste made for industrial polishing and it worked, but I don't have much so I only tried it once. I also don't remember what micron sizes I have.

Also, you can buy very fine and super fine polishing "sandpaper" in small quantities. For example, these, up to 8000 grit:

And these, up to 15000 grit depending on which package you buy:

I've tried some of a different brand and it worked well.

Curious, what polishing method(s) have you tried so far? I've never gotten a "cloudy" surface unless I stopped at too coarse a grit.

Also, I haven't even tried to make optically clear surfaces. All I've done has been decorative, like those in the photos below:

(Note that some of the cast acrylics shown below are NOT made to be clear, but internally a little cloudy, such as the yellow and blue, or opaque like the black ornament. Some, for example the yellow, really catch the light. I carried the yellow ornament into a turning club meeting and several asked me what kind I light I put inside!)

View attachment 68338

JKJ