As I do more closed vessels than anything else, this brings on different requirements, mods etc. This one is not new I came across it several years ago and but by the look of it, it never caught on.

Image 4828 is the collection with additional tips, handles are hollow allowing for length adjustment.

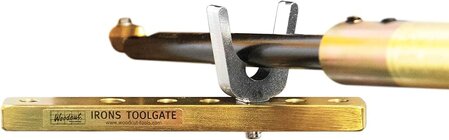

Image 4833 shows the heads along with the depth stop

image 4830 a close-up of the different hollowing heads

image 4834 is the actual business end, a simple piece of HSS steel 3mm thick shaped, etc with a 4" grinder cut-off wheel, silver soldered to the shaft

Image 4828 is the collection with additional tips, handles are hollow allowing for length adjustment.

Image 4833 shows the heads along with the depth stop

image 4830 a close-up of the different hollowing heads

image 4834 is the actual business end, a simple piece of HSS steel 3mm thick shaped, etc with a 4" grinder cut-off wheel, silver soldered to the shaft