Yes, Greg-I got it form Craft Supply. I do agree it is pricey, but it definitely works better than anything I could have rigged up. No, there is no swivel attachment. Their instructions recommend the Rikon version. Dennis, I will go out to my shop and take a picture of how it attaches, and report back. Their instructions are confusing, and it took some figuring.I have been looking into this system. Did you get it from craft-supply? This system is kinda pricey but I like the concept. I understand the swivel for the dust shoot does not come with it and has to be purchased separately?

-

April 2025 Turning Challenge: Turn an Egg! (click here for details) -

Congratulations to Kelly Shaw winner of the March 2025 Turning Challenge (click here for details) -

Congratulations to Ellen Starr for "Lotus Temple" being selected as Turning of the Week for 21 April, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PowerMatic 3520C Initial Review: My Mustard Monster aka "The Beast"

- Thread starter Aaron Harris

- Start date

Dennis-The instructions on the Black Hole system give three mounting options depending on the lathe, one of which is to drill holes for the mounting screws, which I didn't want to try. I went with the included mounting clamps that tighten down under the lathe bed. It is sturdy enough in actual use, though it seems vulnerable to breakage at the bottom arm pivot and the one with the hose hanger if, say, you fell or dropped a heavy wood blank against it. And attached to the massive cast-iron lathe, it's almost laughable by comparison, but it is what it is, and dramatically improved my dust-collecting situation. Here are three pics to give you a better idea:Aaron how is the aluminum track attached to the lathe? Is it PM or other?

Thanks

Dennis.

View from under the lathe bed with aluminum track installed

Another view from underneath

Down along the rail at the two clamps

I hope this helps for anyone else considering this option. Happy Holidays all! Aaron

Regarding black hole dust arm--

How sturdy is the system? Seems like a lot of plastic in the key area's for support? particularly the angle bracket that actually attaches to the rail. Would think metal would be better option.

How sturdy is the system? Seems like a lot of plastic in the key area's for support? particularly the angle bracket that actually attaches to the rail. Would think metal would be better option.

A little confused on this one, can you find a link? Where can you find this?Their instructions recommend the Rikon version.

Dust collection - didnt like mounting a dc hood to the lathe, like the black hole. Rockler has a version that allows many mounting options off the lathe

www.rockler.com

www.rockler.com

It does have an achillea’s heel. The corner joint for the vertical and horizontal pipes is weak, unable to support the arm. I added a $7 modification (bracket and 2 hose clamps)that maintains all the motion of the system and reinforces the corner:

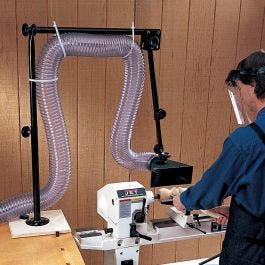

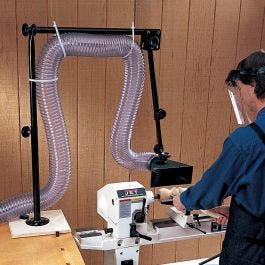

Overarm Dust Hood

Perfect for woodworking machines that lack a dust port, or throw off a lot of dust and shavings: lathes, scroll saws, disc sanders and more.

It does have an achillea’s heel. The corner joint for the vertical and horizontal pipes is weak, unable to support the arm. I added a $7 modification (bracket and 2 hose clamps)that maintains all the motion of the system and reinforces the corner:

Thanks Aaron, the aluminum brackets look like they are solid enough and track looks good also, but like others have said the plastic is the weakest link. I have since ,my message to you, looked at woodturnerswonders track system metal track metal fastening clips and metal brackets for the lights and dust collector shroud. Its cheaper and i think it looks like its more solid, so i think iam going to get his system.

Best to You Arron

Dennis

Best to You Arron

Dennis

I have had the system from Woodturners Wonders for a couple of years now ... very happy with it. Bought it first for my PM3520C, then bought a second setup for my PM2014.Thanks Aaron, the aluminum brackets look like they are solid enough and track looks good also, but like others have said the plastic is the weakest link. I have since ,my message to you, looked at woodturnerswonders track system metal track metal fastening clips and metal brackets for the lights and dust collector shroud. Its cheaper and i think it looks like its more solid, so i think iam going to get his system.

Best to You Arron

Dennis

Great GR, glad to know that you are happy with it and by the tact that you bought another speaks highly of the system. thanks for letting me know.I have had the system from Woodturners Wonders for a couple of years now ... very happy with it. Bought it first for my PM3520C, then bought a second setup for my PM2014.

Best

Dennis

Hi, Ric, concerning the PM swing away you have , do you also have the 18" extension? By pulling the swing away with the rope do you think the 18" extension on the lower setting for larger turnings would work without the swing away getting in the way of turning on the low extension setting on the leg.?I've had my 3520C for about 2 1/2 years now and I still feel warm & fuzzy about it. Feels a little odd to have affection for a big chunk of metal, but it's provided a lot of nice time spent turning. Haven't had a single problem with it and any failed turnings have been my fault. I'm generally left handed and have found that hollowing at the end of the bed is much nicer. I have the tailstock swing-away and found that a loop of rope around the quill handle and hooked to a nearby 2x4 pulls the tailstock further around the pivot and more out of the way.

Enjoy "the Beast" and keep it well fed with blanks and you'll be friends for years to come!

Hey Dennis,

I don't have the extension, so I can't state it definitively, but I think it would work with the extension in the lower mounting position, with or without pulling the tailstock all the way around. The only reason I pull it back a little farther, so it does a full 180 degree swing, is to avoid banging into it when I'm working off the end of the lathe.

I don't have the extension, so I can't state it definitively, but I think it would work with the extension in the lower mounting position, with or without pulling the tailstock all the way around. The only reason I pull it back a little farther, so it does a full 180 degree swing, is to avoid banging into it when I'm working off the end of the lathe.

That makes perfect sense Ric. thanks

Dennis

Dennis

As stated before the swing away works perfectly with the bed extension in the lower position.

I have been wondering how this would work. https://www.amazon.com/gp/aw/d/B07NH9TDHC#Ask

Seems to have plenty of beef, and easy to reposition for way less than mounts made specifically for turning.

Seems to have plenty of beef, and easy to reposition for way less than mounts made specifically for turning.

Don’t see why not. Have to create mounts at each end which isnt a big deal. Hi volume keeps the price low.I have been wondering how this would work. https://www.amazon.com/gp/aw/d/B07NH9TDHC#Ask

Seems to have plenty of beef, and easy to reposition for way less than mounts made specifically for turning.

I have been wondering how this would work. https://www.amazon.com/gp/aw/d/B07NH9TDHC#Ask

Seems to have plenty of beef, and easy to reposition for way less than mounts made specifically for turning.

I used a similar monitor arm, which I clamped to a light weight saw horse. It works fine, but in my application the articulated monitor support can't lft the "weight" of the dust collection hood & hose. So I don't have much adjustability vertically. Lateral adjustment is either via the arm or just moving the saw horse. Vertical adjustment is not that critical once I put the hood at the right height. All in all, it works well enough.

This is an old picture. The lathe has since been moved, and the saw horse parallels the bed.

I just converted to using this articulated arm. It’s made for holding dock lights or fans, but it’s easy to attach anything you want and it’s really strong. I really like that it doesn’t get in the way of the banjo at all and it can easily range from one end of the lathe to the other. At some point I’ll probably change out the dust hood to a bell shape, but this will do in the meantime.