I have been studying some old turning text books (very old) for turning spindles with an oval profile, like a hammer handle, pick handle, etc. However, lets say I wanted to turn a fish. A round body fish is easy, a fish with a body that is ovoid in cross section and with flattened tail, is a whole other game. A few months ago, I wanted to turn a whale, with a tail flipped up. After several attempts, I got close, but failed to pay enough attention to how I did it to replicate the effort. I see lots of off center spindle goblets etc, that remind me of an internal combustion auto crankshaft. For instance, it should be possible to turn a spindle into a single spiral on the lathe. Sort of a giant rotini in wood. And I can plan that to an extent. Is there a guide to planning such off center turnings. So far I have been sitting down figuring angles to shift the centers and diameters for about every inch all along the piece.

-

April 2025 Turning Challenge: Turn an Egg! (click here for details) -

Congratulations to Kelly Shaw winner of the March 2025 Turning Challenge (click here for details) -

Congratulations to Ellen Starr for "Lotus Temple" being selected as Turning of the Week for 21 April, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Planning an off center turning. is there a guide?

- Thread starter Perry Hilbert

- Start date

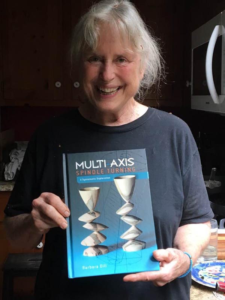

Have you seen Barbara Dill's book "Multi Axis Spindle Turning"? I think it's a very good read:

I've seen Mark Sfirri demonstrate a lot of these techniques, too, but I don't know if he's published anything.

Multi-Axis Spindle Turning: A Systematic Exploration: Dill, Barbara: 9780764355349: Amazon.com: Books

Multi-Axis Spindle Turning: A Systematic Exploration [Dill, Barbara] on Amazon.com. *FREE* shipping on qualifying offers. Multi-Axis Spindle Turning: A Systematic Exploration

a.co

I've seen Mark Sfirri demonstrate a lot of these techniques, too, but I don't know if he's published anything.

Have you seen Barbara Dill's book "Multi Axis Spindle Turning"? I think it's a very good read:

I've seen Mark Sfirri demonstrate a lot of these techniques, too, but I don't know if he's published anything.

Barbara Dill's book is invaluable, especially for multiaxis spindle turning. Absolutely worth having. She has several demo videos linked on her website, as well as handouts and her articles in AW

Multi axis Teaching Tools: Book, Papers, and Videos - ss_site_title

MULTI AXIS TEACHING TOOLS: BOOK, PAPERS AND VIDEOS MY BOOK: MULTI AXIS SPINDLE TURNING: A SYSTEMATIC EXPLORATION I recieved my copy of this book in May, 2018. It is now available through book stores and Amazon. The glee reflected in my face indictes the relief I had to finally see the book […]

www.barbaradill.com

Several years ago Sfirri had a book (self-published?) with plans for a number of his signature pieces that I bought from him at a symposium demo. Dill's book and articles would be more useful.

I've done several fish. No matter how much you plan, it is only at the lathe that the thing comes together -- or doesn't. Practice, and multiple attempts, should help. I've never had a first attempt at a new multiaxis idea turn out wonderful. A few rounds of "that's clearly not the way" and "now that's better" seem to be the usual course.

I've thought about turning fish, and while I've not attempted it yet, I suspect a good alternative way to approach it is using a lost wood process, where 3 pieces are laminated together using paper, the two outside pieces will be kept and glued together again, after the middle piece is discarded. The trick will be to draw up plans to determine how thick the middle piece can be for a given taper from wide part to the tail.

Curious to see what you come up with. I'm personally fascinated by tuna, of all sizes as you can tell by my picture.

Curious to see what you come up with. I'm personally fascinated by tuna, of all sizes as you can tell by my picture.

- Joined

- Apr 27, 2004

- Messages

- 9,161

- Likes

- 5,768

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

I do a fish tail on some hollow forms the outline of the tail is turned and I bandsaw a wave in the tail on the vertical axis.

These forms are turned from a block on the order of 6x8x15.. the sphere is turned off center so the form can stand up

The tail looks a little bit like an unholllowed wavy goblet with a 1/2” stem.

I leave the last 1/4” as unturned square for a flat to support a band cut.

I cut a wave in the tail by standing behind the blade with the blade against the narrow part joins the tail to the form and pulling the form toward me curving the cut left and right. The cut the other side going for an even thickness.

These forms are turned from a block on the order of 6x8x15.. the sphere is turned off center so the form can stand up

The tail looks a little bit like an unholllowed wavy goblet with a 1/2” stem.

I leave the last 1/4” as unturned square for a flat to support a band cut.

I cut a wave in the tail by standing behind the blade with the blade against the narrow part joins the tail to the form and pulling the form toward me curving the cut left and right. The cut the other side going for an even thickness.

- Joined

- Apr 27, 2004

- Messages

- 9,161

- Likes

- 5,768

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

I've thought about turning fish, and while I've not attempted it yet, I suspect a good alternative way to approach it is using a lost wood process, where 3 pieces are laminated together using paper, the two outside pieces will be kept and glued together again, after the middle piece is discarded.

That works. Also 2 off set centers will give the same shape without the gluing on maybe a better shape with the lost wood.

Here is a slide for a 2 sided napkin ring

For a fish you can use the centers on the same sides to turn the body. then angle it using centers on opposite sides to taper toward the tail and nose. Sanding can blend these together. Or carbide burrs for shaping.

Dale Nish used a similar technique for an oval weed pot in one of his books.

Another technique is the inside out method. Turn 4 fish at a time. Put 4 squares together turn a profile.

Flip the 4 squares and turn a matching profile.

Be sure you don’t to cut through to the inside. Strapping tape on is a good safety precaution to keep prices together if you get over aggressive

Last edited:

This is a link to video about eccentric turning using a chuck from Axminster. Perhaps seeing someone doing offsetting versus or including rotating will be helpful to understand the princples. Although I own this chuck, I don't think I'd try turning a fish of any significant size with it.

Somewhere I read Barbara Dill's description of her process of learning (?perfecting) off center spindle turning. If I remember correctly, it was a years long process, involved hundreds of trial pieces, and was totally experiential. The committment and industry required was astounding. She will share with you what she learned over those many years.

I have turned fish up to 16 inches long on a lathe just between centers. Getting the body with out the dorsal fins or pectoral fins is relatively easy.This is a link to video about eccentric turning using a chuck from Axminster. Perhaps seeing someone doing offsetting versus or including rotating will be helpful to understand the princples. Although I own this chuck, I don't think I'd try turning a fish of any significant size with it.

My dismal attempt at a whale 10 inches long from a 2x4 the tail was a round cone that I sanded flat (I burned it before painting it a grayish white to look weathered) . Already sold to a person for their beach house.) I planned the angles and diameters at various places and adjusted the placement of the centers to achieve those or as close as I could. It was turned in five sets of centers (5 at each end.). the tail required the tail side to be almost at the top of the blank and the head end was almost off the bottom of the head end.

The wood was just pine, and the final turned finish was plain pine, but I did get the general shape I was looking for.

Last edited: