I appreciate the suggestions. It will be a learning curve. I will need to develop a schedule for drying. In addition to using a timer, I have options to slow the rate of temperature rise. I have four 1” holes in the top for my secondary use. I could start leaving all four uncovered and cover one each day slowing the temperature rise. I could also turn it off at night simulating a solar kiln. Adding the pan of water seems like a good idea. Another option is getting some lower watt light bulbs from the Restore. All in all I am satisfied with my design and build. There may be a few failures, but I believe I will be successful using this kiln.

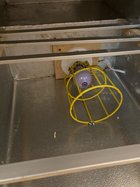

holes in top

This is the temperature showing the drop overnight as the outside temperature went down. Humidity also dropped to the lowest reading g so far. I’ll take a look at the piece today and check the weight.

holes in top

This is the temperature showing the drop overnight as the outside temperature went down. Humidity also dropped to the lowest reading g so far. I’ll take a look at the piece today and check the weight.