That is what I have, the one by Lincoln Electric.Yes, that is it.

-

January 2026 Turning Challenge: Turned and Bent! (click here for details) -

Congratulations to Phil Hamel, People's Choice in the December 2025 Turning Challenge (click here for details) -

Congratulations to David Wyke for "Maple Platter #567" being selected as Turning of the Week for January 5, 2026 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Face Shield part 2

- Thread starter Michael Nathal

- Start date

I decided on the Trend. I figure the weight shouldn't be too much more bothersome than the hard hat I've been wearing every day for 34 years, I should be able to get used to it.

Just watched Reed's video, excellent information. Definitely going to modify how I do pull cuts on the outside of the bowl. Easier to stay out of the way with push cuts but in some situations I still pull cut.

I have a UVEX Bionic, this thread makes me thing of upgrading. Wondering why the Lincoln is better, they both are Z87.1/Z94.3?

I have a UVEX Bionic, this thread makes me thing of upgrading. Wondering why the Lincoln is better, they both are Z87.1/Z94.3?

Has anyone has experienced a serious head injury that required surgery or more than a few stiches while wearing a Uvex helmet? I'm not talking about blunt force trauma while doing something risky like spinning an unbalanced 30# block of wood at high speeds with a chuck only and no tailstock engaged.

I don't know of anyone....but I still think that even a great quality face shield is only 1/2 of the answer to our needs. You lungs need protection too. And - even while turning...not just sanding - we create dust that is harmful to our lungs. So - my vote is for a Trend or JSP Powercap...at a minimum. But really - if you look at the money we invest in our lathe, and tools...isn't it rational that we spend enough to protect our health? So, I currently use a powered PAPR -Has anyone has experienced a serious head injury that required surgery or more than a few stiches while wearing a Uvex helmet? I'm not talking about blunt force trauma while doing something risky like spinning an unbalanced 30# block of wood at high speeds with a chuck only and no tailstock engaged.

PX5 PAPR | Powered Air Purifying Respirator | RPB Safety

The RPB PX5 is a compact and versatile PAPR that changes the way people experience clean filtered air across multiple industries.

A few weeks ago I had a come to Jesus moment. I have had a constant struggle convincing my self to wear a face shield. Recently I have had 3 bowls fall apart and this convinced me I had to wear one. Started to do so and my very next bowl split and threw 1/2 of it right into my face. Without my shield, I am pretty sure I would have been seriously injured if not dead. So glad I overcame my stubborn stupidly.

Right now I am experimenting with a heavy lexan full face respirator I got from Amazon and an extra CPAP machine I had. Took off one of the filters and attached the CPAP to it. I'll let you know how it works but so far I think it will be ok. Just need to figure how to protect it from infiltrating dust into the CPAP. I am thinking an enclosed box with filters.

Pat

Right now I am experimenting with a heavy lexan full face respirator I got from Amazon and an extra CPAP machine I had. Took off one of the filters and attached the CPAP to it. I'll let you know how it works but so far I think it will be ok. Just need to figure how to protect it from infiltrating dust into the CPAP. I am thinking an enclosed box with filters.

Pat

Not me Carl, but I saved this picture and have used it to remind turners what WILL happen when they insist on high speed turning, got this 4 or 5 years ago.Has anyone has experienced a serious head injury that required surgery or more than a few stiches while wearing a Uvex helmet? I'm not talking about blunt force trauma while doing something risky like spinning an unbalanced 30# block of wood at high speeds with a chuck only and no tailstock engaged.

Though one more thing, you can have the best protection in the world, it will not protect you from the truck coming down the highway if you go stand in front of it.

Attachments

We are not allowed to stand in front of trucks in this country Leo. Well...there are a bunch of folks in D.C. that we wish WOULD go stand in front of a truck.....Not me Carl, but I saved this picture and have used it to remind turners what WILL happen when they insist on high speed turning, got this 4 or 5 years ago.

Though one more thing, you can have the best protection in the world, it will not protect you from the truck coming down the highway if you go stand in front of it.

Pat,A few weeks ago I had a come to Jesus moment. I have had a constant struggle convincing my self to wear a face shield. Recently I have had 3 bowls fall apart and this convinced me I had to wear one. Started to do so and my very next bowl split and threw 1/2 of it right into my face. Without my shield, I am pretty sure I would have been seriously injured if not dead. So glad I overcame my stubborn stupidly.

Right now I am experimenting with a heavy lexan full face respirator I got from Amazon and an extra CPAP machine I had. Took off one of the filters and attached the CPAP to it. I'll let you know how it works but so far I think it will be ok. Just need to figure how to protect it from infiltrating dust into the CPAP. I am thinking an enclosed box with filters.

Pat

View attachment 40957

If you've had 4 bowls blow apart in a short period of time, you should probably reassess more than just wearing a face shield (though that's a terrific idea). Maybe you should be more selective about the wood you're putting on the lathe, or how you're mounting, or the speed you're turning, or how you're using your tools. Also, if you got hit in the face, you were probably standing in the 'line of fire' and that's another valuable lesson to gain from the experience. This is a situation where a mentor would be helpful, even though it's not easy out there in the soybeans. Or apple orchards.

What is the story behind this pic? Do you know if this turner was not wearing a helmet of any type? Still the pic makes a good reminder that high speed turning with unsound, unbalanced or unsafely mounted wood is foolish.Not me Carl, but I saved this picture and have used it to remind turners what WILL happen when they insist on high speed turning, got this 4 or 5 years ago.

Though one more thing, you can have the best protection in the world, it will not protect you from the truck coming down the highway if you go stand in front of it.

IIRC Karl the guy was wearing cheap face shield, though I'm not sure of the rest of this accident, as things get told and memories seem very fuzzy or not at all, the picture is just a very real reminder what does happen if not taking advice seriously .What is the story behind this pic? Do you know if this turner was not wearing a helmet of any type? Still the pic makes a good reminder that high speed turning with unsound, unbalanced or unsafely mounted wood is foolish.

Your right on all counts. Bottom line I have been too aggressive. I have slowed down and now take my time and chill. How do you stay out of the line of fire??Pat,

If you've had 4 bowls blow apart in a short period of time, you should probably reassess more than just wearing a face shield (though that's a terrific idea). Maybe you should be more selective about the wood you're putting on the lathe, or how you're mounting, or the speed you're turning, or how you're using your tools. Also, if you got hit in the face, you were probably standing in the 'line of fire' and that's another valuable lesson to gain from the experience. This is a situation where a mentor would be helpful, even though it's not easy out there in the soybeans. Or apple orchards.

Pat

- Joined

- Feb 28, 2021

- Messages

- 1,782

- Likes

- 1,595

- Location

- Roulette, PA

- Website

- www.reallyruralwoodworks.com

Simply put, it means not standing dead-on in front of the spinning work piece... for me, that generally means I am standing side-on to the lathe with gouge in front of me, moving it sideways along the lathe ways / toolrest... and that mostly applies in bowl turning and other large items that are not supported between centers.. only very rarely do I end up standing directly in front of the piece , and almost invariably only on small spindle turnings or small (less than 5 inch diameter) bowls when I need to focus in on some small detail work, etc. and absolutely never stand in front of the piece when it is not in balance and rounded, or if it is a natural edge (bark flying off can HURT, trust me.. got a nasty bruise on my shoulder from one chunk of bark off an apple tree.. and on my shoulder *because* I wasn't in "line of fire".. but it still hurt) but even with relatively "safe" spindle turnings your workpiece could still split apart and go flying if you get a bad catch... and of course, bowls can develop cracks as they are being worked, even between centers they can split in half and quite literally "explode", so as much as possible it means just standing to one side or the other.How do you stay out of the line of fire??

Pat

A good way to stay out of the line of fire of bark, shavings, sap, unattached chunks of wood, etc, is to turn the outside of the bowl left handed. I.e. left hand on the handle of the gouge, right hand pressing the gouge against the tool rest. Especially if you use an overhand grip with your right hand, you can position your body much closer to the tail stock end of the lathe and away from the zone where shavings and exploding bowls tend to fly.How do you stay out of the line of fire??

I do the initial rough out for the outside of most of my bowls turning left handed. Once the shape is close to what I'm after, I'll turn off the lathe, inspect the blank to be make sure everything looks ok, then switch to normal, right handed grip to make the final cuts.

Turning the inside of bowls, your body should naturally be out of the line of fire already.

Dave Landers

Beta Tester

How do you stay out of the line of fire?

A good way to stay out of the line of fire of bark, shavings, sap, unattached chunks of wood, etc, is to turn the outside of the bowl left handed.

I look at it this way - The cut you are making combined with the bevel on the gouge determines where the gouge needs to be (that is, what angle the handle is at so you get the cut you want).

The gouge position is determined by the cut, and you get to choose which side of that handle you want to stand on.

Sometimes, one side or the other is blocked by the lathe (headstock or tailstock). Other times, one side is in the line of fire (where the bits go when they fling off the spinning piece). Etc.

I don't think of the "which side" choice as "right-" vs "left-handed". Because for many cuts, all my hands are doing is holding the gouge next to my body or on the tool rest - not a lot of coordination needed for that. And my body moves to make the cut.

- Joined

- Feb 6, 2010

- Messages

- 3,475

- Likes

- 2,555

- Location

- Brandon, MS

- Website

- threeringswoodshop.square.site

I think he was wearing a Z87 but turning some really bad wood that should have been in the fire . That was maybe 6-8 years ago and the story was all over Facebook. From what I remember the wood was very questionable and he was turning highspeed. It blew up when the tool touched the wood.What is the story behind this pic? Do you know if this turner was not wearing a helmet of any type? Still the pic makes a good reminder that high speed turning with unsound, unbalanced or unsafely mounted wood is foolish.

Odie

Panning for Montana gold, with Betsy, the mule!

Looking at my own woodturning journey as a newbie, back then I tended to push the rpm's higher than need be.....because, let's face it, a tool that isn't as sharp as it could be, does produce a cleaner cut at a faster rpm.

As it was for me, the obvious solution was to learn that what I thought was sharp, wasn't as sharp as it could be. When I discovered that I could get my tools sharp-ER, I also found that a slower rpm along with sharper tools and tool handling skills, worked much better than faster rpm's, along with tools that could be sharper.

As with a few other experienced turners here in this thread, the rpm is determined by isolating the rpm to a speed that produces the least felt vibration. Finding that best rpm with the least vibration, is a skill that you can easily develop by gently feeling the lathe bedways with your fingertips while adjusting the speed.....and, then learning to refine that sense of touch over time.

-----odie-----

As it was for me, the obvious solution was to learn that what I thought was sharp, wasn't as sharp as it could be. When I discovered that I could get my tools sharp-ER, I also found that a slower rpm along with sharper tools and tool handling skills, worked much better than faster rpm's, along with tools that could be sharper.

As with a few other experienced turners here in this thread, the rpm is determined by isolating the rpm to a speed that produces the least felt vibration. Finding that best rpm with the least vibration, is a skill that you can easily develop by gently feeling the lathe bedways with your fingertips while adjusting the speed.....and, then learning to refine that sense of touch over time.

-----odie-----

In the case a chunk with a crack is deemed so good it HAS to be turned running superglue into the crack the day before will help it hold together. Sometimes I will follow that with medium CA as a filler. Stand out of the danger zone is good advise whatever the machine is you are running.

Good advice. I’ve been learning to sharpen a lot especially with wet wood. Curious, what do you consider a slower rpm/size of blank?Looking at my own woodturning journey as a newbie, back then I tended to push the rpm's higher than need be.....because, let's face it, a tool that isn't as sharp as it could be, does produce a cleaner cut at a faster rpm.

As it was for me, the obvious solution was to learn that what I thought was sharp, wasn't as sharp as it could be. When I discovered that I could get my tools sharp-ER, I also found that a slower rpm along with sharper tools and tool handling skills, worked much better than faster rpm's, along with tools that could be sharper.

As with a few other experienced turners here in this thread, the rpm is determined by isolating the rpm to a speed that produces the least felt vibration. Finding that best rpm with the least vibration, is a skill that you can easily develop by gently feeling the lathe bedways with your fingertips while adjusting the speed.....and, then learning to refine that sense of touch over time.

-----odie-----

Odie

Panning for Montana gold, with Betsy, the mule!

Good advice. I’ve been learning to sharpen a lot especially with wet wood. Curious, what do you consider a slower rpm/size of blank?

Howdy Rachel......

Size of the bowl is less important than getting the best rpm with the least vibration. Every block of wood is different, and you'll find that some large bowls are capable of spinning faster, and vibrating less, than some smaller bowls. There is no universal formula for determining best rpm, based on size.

Finding the best rpm is the key. You're just not going to get the cleanest cut you can possibly get, if the inherent vibration is too much. With some bowls, it's not possible to have zero vibration, or any detectable vibration, but it's important to have the least detectable vibration.

Of course, the best rpm is only a small element to the total conditions and skills needed to get the finest cleanest cut you are capable of, but it is an important one, nonetheless.

I concentrate on bowls from about 6" to 14 1/2" in diameter, and almost never go slower than around 4-500 rpm, or faster than about 8-900 rpm. These rpm's work for me, but not necessarily for anyone else. My lathe is 525 lbs, and is solidly bolted to the cement floor. Heavier and lighter lathes secured differently may adjust to some other "best rpm" for the same bowl, than I would determine for my circumstances.

-----odie-----

Thank you Odie this is valuable information.Howdy Rachel......

Size of the bowl is less important than getting the best rpm with the least vibration. Every block of wood is different, and you'll find that some large bowls are capable of spinning faster, and vibrating less, than some smaller bowls. There is no universal formula for determining best rpm, based on size.

Finding the best rpm is the key. You're just not going to get the cleanest cut you can possibly get, if the inherent vibration is too much. With some bowls, it's not possible to have zero vibration, or any detectable vibration, but it's important to have the least detectable vibration.

Of course, the best rpm is only a small element to the total conditions and skills needed to get the finest cleanest cut you are capable of, but it is an important one, nonetheless.

I concentrate on bowls from about 6" to 14 1/2" in diameter, and almost never go slower than around 4-500 rpm, or faster than about 8-900 rpm. These rpm's work for me, but not necessarily for anyone else. My lathe is 525 lbs, and is solidly bolted to the cement floor. Heavier and lighter lathes secured differently may adjust to some other "best rpm" for the same bowl, than I would determine for my circumstances.

-----odie-----

I have seen this as well regarding my lathe and turning. I’ve re-assessed after rounding a blank and to see what feels safe and less vibration as I go along.

How does the JSP Power Cap due for those of us who wear glasses? Do they fit under the helmet/visor? How about the issue of glasses fogging up? I like the looks of the JSP.

I'd like to also ask to piggyback on this question, how are the face shields of these systems, i.e PAPR system or the JSP in comparison to a Uvex Bionic face shield for resistance?How does the JSP Power Cap due for those of us who wear glasses? Do they fit under the helmet/visor? How about the issue of glasses fogging up? I like the looks of the JSP.

Odie

Panning for Montana gold, with Betsy, the mule!

Here's a video of the JSP Powercap. Looks like an interesting new design. When he turned it on, it did seem a bit noisy. I like that it's completely self-contained unit, while my Airstream helmet requires the battery pack to clip to your belt.

View: https://youtu.be/_Bjf41QYb54

Even though I have a 30 year old Airstream helmet that works perfectly, I'm mostly using a cheap Resp-o-rator for everyday use. The big disadvantage to the powered respirators, is the weight, all the gadgetry involved, the noise, and inconvenience of putting it on and taking it off over and over again during a turning session. The Resp-o-rator is so simple, light, and convenient.....and it will filter dust as well as any of the powered respirators. It simply dangles around your neck when not used, and fits perfectly under the UVEX Bionic faceshield.

The drawback to the Resp-o-rator is there is a learning curve to using it. I fully understand why some turners can't get past that initial stage. It's like scuba diving in your shop! It's not about the money.....I'm willing to pay for a powered respirator that is super convenient to use. It's just that there is nothing out there that has the downright convenience that the Resp-o-rator has.

It's not about the money.....I'm willing to pay for a powered respirator that is super convenient to use. It's just that there is nothing out there that has the downright convenience that the Resp-o-rator has.

-----odie-----

Even though I have a 30 year old Airstream helmet that works perfectly, I'm mostly using a cheap Resp-o-rator for everyday use. The big disadvantage to the powered respirators, is the weight, all the gadgetry involved, the noise, and inconvenience of putting it on and taking it off over and over again during a turning session. The Resp-o-rator is so simple, light, and convenient.....and it will filter dust as well as any of the powered respirators. It simply dangles around your neck when not used, and fits perfectly under the UVEX Bionic faceshield.

The drawback to the Resp-o-rator is there is a learning curve to using it. I fully understand why some turners can't get past that initial stage. It's like scuba diving in your shop!

-----odie-----

Last edited:

Dave Landers

Beta Tester

The headgear for the CleanAir PAPR from Peke Safety is a BionicI'd like to also ask to piggyback on this question, how are the face shields of these systems, i.e PAPR system or the JSP in comparison to a Uvex Bionic face shield for resistance?

"Premium impact resistant polycarbonate lens is 90% thicker than a traditional face shield (0.077"" vs 0.040"") for enhanced protection" from the web site.@John Hicks , is this the one you mentioned?

It does seem better.OMNIShield™ Clear Face Shield - Standard - K3750-1

www.lincolnelectric.com

It does seem better, my next mask.

I use a N95 plain mask for breathing, rather then a powered unit. A bit less weight. The one I use is a

Kimberly-Clark PROFESSIONAL N95 Pouch Respirator (53358), NIOSH-Approved, Made in U.S.A., Regular Size, from amazon.

It has a large filter area that makes you look like daffy duck with a white beak but has straps that go around the head rather then behind the ears. Better for hearing aid people. The straps are much more sturdy then on the 3M masks.

Stu

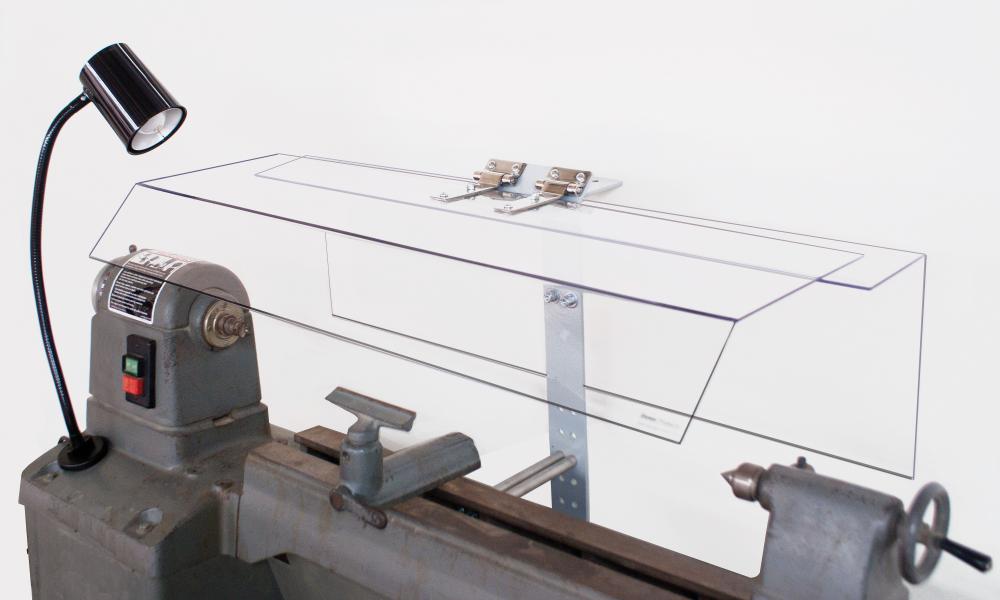

I wonder why there is not a lexan cage that can replace the heavy wire contraption that comes with most lathes? Probably cost and the fact that it would be hard to keep from scratching it up.

John, I would think that the wire cage is o.k. (?) for spindle work….. but don’t see it as workable for bowls and hollow vessels. I think it would interfere with my body/ arm positioning. Thus I prefer a good battery powered PAPR that protects my face and head, and provides me with clean air too.I wonder why there is not a lexan cage that can replace the heavy wire contraption that comes with most lathes? Probably cost and the fact that it would be hard to keep from scratching it up.

- Joined

- Apr 27, 2004

- Messages

- 9,309

- Likes

- 6,082

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

The lathes in school shop classes often had a clear shield in an aluminum frame the was hinged to posts that bolted to the back of the lathe. 7 it had a couple of latch positions. Ok for turning a baseball from dry wood between centers .I wonder why there is not a lexan cage that can replace the heavy wire contraption that comes with most lathes? Probably cost and the fact that it would be hard to keep from scratching it up.

impractical for wet wood get spray line coatings you can’t seen through. you should be able to make one.

google delta lathe shield and you get lots of hits

these are examples of what you get from google.. I have no knowled of this company use diligence in contacting

Wood Lathe Shields | Danray Products

Visit Danray Products for wood lathe shields. We carry a full line of wood lathe shields for your machine safeguarding needs.

Odie

Panning for Montana gold, with Betsy, the mule!

Some enterprising person could probably make some money, if he designed a face shield that attaches to the front of a UVEX bionic face shield......similar to a football helmet. Just drill a few holes and attach it.

-----odie-----

-----odie-----

One of the major problems with Lexan (polycarbonate) is that it scratches easily. This can be prevented by proper cleaning. There was a topic on that a bit ago but see;

www.acplasticsinc.com

www.acplasticsinc.com

Bus windows were being broken by rocks so they tried polycarbonate but it scratched easily. So they developed a special type to withstand that but it is costly. See;

https://www.acplasticsinc.com/categories/clear-gp-sheet

As an alternative you can buy acetate sheet and make an overlay to fit your mask. This is sold as an accessory by some helmet manufacturer (Trend). It used tape at the ends to hold it in place. For the material see as an example.

https://www.dickblick.com/products/grafix-clear-acetate-sheets-pads/

for material that seems to be what they sold.

Stu

Cleaning Polycarbonate Sheets - A&C Plastics

How to properly clean and maintain your polycarbonate sheets without damaging them. Read more today at A&C Plastics.

Bus windows were being broken by rocks so they tried polycarbonate but it scratched easily. So they developed a special type to withstand that but it is costly. See;

https://www.acplasticsinc.com/categories/clear-gp-sheet

As an alternative you can buy acetate sheet and make an overlay to fit your mask. This is sold as an accessory by some helmet manufacturer (Trend). It used tape at the ends to hold it in place. For the material see as an example.

https://www.dickblick.com/products/grafix-clear-acetate-sheets-pads/

for material that seems to be what they sold.

Stu

Odie

Panning for Montana gold, with Betsy, the mule!

You know......I would buy a football type face guard to mount to my UVEX Bionic faceshield. If I could wish, I'd make it light, and mounted with quick disconnect pins, so that the clear shield could be cleaned easily. It wouldn't have to have lots of metal, like a lineman's faceguard......more like a quarterback's faceguard.

Should be simple and kind of like this, only it should be attached to the Bionic faceshield on the outside. This is a ladies softball face guard. I have one just like this that I use from time to time, but it fits under the Bionic faceshield, and doesn't allow me to use my Resp-o-rator at the same time:

Here is a video that is inspirational, just in case anyone consideres making a woodturner's face guard, and selling them:

View: https://youtu.be/Uia1ovW_WhU

-----odie-----

Should be simple and kind of like this, only it should be attached to the Bionic faceshield on the outside. This is a ladies softball face guard. I have one just like this that I use from time to time, but it fits under the Bionic faceshield, and doesn't allow me to use my Resp-o-rator at the same time:

Here is a video that is inspirational, just in case anyone consideres making a woodturner's face guard, and selling them:

-----odie-----

I know this is an older post, and I had forgotten that I had put a question out here about the JSP Power Cap. I ended up buying one of those units. It works incredibly well. I wear glasses and there is no fogging of them at all. With the powered fan that is blowing inside the mask, it is actually very cool and comfortable to wear, even in the middle of summer. I am highly impressed with it.

I love my Power Cap! Light and comfortable.

Thinking that one can protect oneself from the impact of a pound or more of wood coming at you, at speed, is folly. I feel that the confidence folks have in this ability is dangerous. Someone else suggested that using ppe to play on the highway won’t end well.

Looking at the popular face shields/filtration systems, they are all head mounted, more ’set on‘ than securely anchored. And please consider that hinge. It‘s only rated for light objects. It seems that with this set-up that something impacting with reasonable energy will, within a nano second, shove that shield right into your face. It will absorb some energy, not much though, it doesn’t weigh enough, and isn’t securely mounted.

In one way or another, your body is going to absorb the energy of the flying piece. So, the best bet is to spread the load over as much area as possible. 3m and others make masks with a full face surround. They also have a more robust shield, made stronger because it’s supported at all the edges, not just at the top, and the 3m shield are thicker in the center areas. The result is the energy would be delivered to the edges of your face, putting the load on your forehead, cheeks and chin. Not your nose, mouth and eyes! These aren’t as comfortable as lighter outfits, and give zero protection to the top of your head, even less than hinged shields.

Someone suggested incorporating a hard hat for head protection, so I checked on the specs, osha regs. Great protection for falling pieces, and side impact has been added to the design. Protection from something coming from below is zero. So, maybe it helps you feel safe? Look protected?

Throwing more money at it seems to be what helps folks feel safe, but that money is only spend on fancy breathing protection. No upgrade or change at all to the basic idea of just hanging something on your head for impact protection.

I think face shields work well for spindle turning, smaller diameter and usually lighter work. Other strategies are needed for heavy wood turning. A thought I had, if one wanted an impact shield, would be to anchor it to your torso. A curved shields that extend to your chest, while still mounted to your head is a possibility.

Until a better solution presents itself, we need to understand the wood, recognize dangers (faux crotches and similar) and always being ‘out of the way’! Bowl turning, especially roughing is ALWAYS done standing to the right of the blank (tailstock end). It’s the efficient way to remove stock and keeps you out of the way. When reversing to do the inside you stand again, to the right of the piece. No work should come off the lathe unexpectedly, but if it does it’ll fly pass your left shoulder.

Buy good ppe. Make sure it’s comfortable enough that you’ll wear it religiously and safe enough regarding breathing protection. Then ALWAYS incorporate your best bet for safety, your brain. It’s the best ppe available.

Looking at the popular face shields/filtration systems, they are all head mounted, more ’set on‘ than securely anchored. And please consider that hinge. It‘s only rated for light objects. It seems that with this set-up that something impacting with reasonable energy will, within a nano second, shove that shield right into your face. It will absorb some energy, not much though, it doesn’t weigh enough, and isn’t securely mounted.

In one way or another, your body is going to absorb the energy of the flying piece. So, the best bet is to spread the load over as much area as possible. 3m and others make masks with a full face surround. They also have a more robust shield, made stronger because it’s supported at all the edges, not just at the top, and the 3m shield are thicker in the center areas. The result is the energy would be delivered to the edges of your face, putting the load on your forehead, cheeks and chin. Not your nose, mouth and eyes! These aren’t as comfortable as lighter outfits, and give zero protection to the top of your head, even less than hinged shields.

Someone suggested incorporating a hard hat for head protection, so I checked on the specs, osha regs. Great protection for falling pieces, and side impact has been added to the design. Protection from something coming from below is zero. So, maybe it helps you feel safe? Look protected?

Throwing more money at it seems to be what helps folks feel safe, but that money is only spend on fancy breathing protection. No upgrade or change at all to the basic idea of just hanging something on your head for impact protection.

I think face shields work well for spindle turning, smaller diameter and usually lighter work. Other strategies are needed for heavy wood turning. A thought I had, if one wanted an impact shield, would be to anchor it to your torso. A curved shields that extend to your chest, while still mounted to your head is a possibility.

Until a better solution presents itself, we need to understand the wood, recognize dangers (faux crotches and similar) and always being ‘out of the way’! Bowl turning, especially roughing is ALWAYS done standing to the right of the blank (tailstock end). It’s the efficient way to remove stock and keeps you out of the way. When reversing to do the inside you stand again, to the right of the piece. No work should come off the lathe unexpectedly, but if it does it’ll fly pass your left shoulder.

Buy good ppe. Make sure it’s comfortable enough that you’ll wear it religiously and safe enough regarding breathing protection. Then ALWAYS incorporate your best bet for safety, your brain. It’s the best ppe available.

Hmm, I have a friend that uses an emergency room type of fabric head cover with a respirator blowing air through it. It wouldn't offer much protection since it is very light weight, but he turns a lot of trinkets. He can't wear heavier head things because of neck problems. This makes me wonder if some type of helmet that sits on the shoulders would work. Of course, it would be difficult to fit for every one since our bodies are all pretty different, but the shoulders are designed to take the weight better than head and neck....

Still will say that the first line of defense is to stand out of the line of fire, ALWYWS!

robo hippy

Still will say that the first line of defense is to stand out of the line of fire, ALWYWS!

robo hippy

In the 80's I worked a turret lathe in a machine shop for a time. I saw a guy get killed one day at work. He was de-burring a part with a mill file. The file caught and got shoved into his guts along with all those metal filings. He should have been wearing a leather apron, but it was too hot. He should have had a handle on the file, but it was lost. He made it to the hospital but the metal filings cased an infection and he died a few days later.

Lots of shoulda coulda woulda involved. Still dead.

It will happen fast when it happens.

Lots of shoulda coulda woulda involved. Still dead.

It will happen fast when it happens.

Replying here to this old post by Leo in a thread that has been recently resurrected...How do I stand out of the line of fire ??

I turn outboard that way I'm never in the line of fire, and I have never had a bowl blow up on me, max RPM on my big lathe is 1510 rpm, and I usually turn at 550 or 800 rpm.

Like Leo, I too also turn everything outboard except for the rare spindle piece that I do between centres. Been doing it that way for over 50yrs. Turning outboard both keeps me out of the firing line and it's much kinder to my ageing back.

I find that there are a number of advantages to outboard turning, but I think it is important to have a stop button that is moveable to where you don't need to go through the firing line to stop the lathe. That means it can't be attached to the lathe unless it is on a swing away arm. A detachable control with a cable or remote stop button are the other options.

Back on the topic of masks & hoods... I always wear a positive air pressure mask while at the lathe and sharpening station. I do this primarily for my respiratory health and consider any impact protection that it might afford as a bonus. A high impact may kill me instantly while the fine wood dust could kill me very slowly while I fight for every breath to the end...

Yes Neil I did realize this when I build the outboard, also as I did initially use an electric switch and pinched the wire  , I did change that to air activated switches, added a magnet to the bottom so that I could place these switches right underhand, very handy and safe.

, I did change that to air activated switches, added a magnet to the bottom so that I could place these switches right underhand, very handy and safe.

Shown here in the picture.

Shown here in the picture.