Something to think about..... when using a threading jig the cuts should be done with a "climb" cut. Imagine you're using a router on the edge of a board, a climb cut would be feeding from the opposite direction that's normally done. A climb cut is difficult to do on the edge of a board because it wants to self feed and get out of control, not so on a threading jig though. A climb cut lessens the tear out issues threading soft woods.

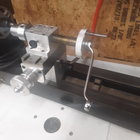

The picture shows a bottle thread I like to use. A little different concept than a 60 degree vee thread. With this type thread there can quite a bit of looseness to accommodate seasonal wood movement. 4 tpi, less than a full turn to open/close. It gives me carpal tunnel syndrome just thinking about the many turns to get a fine threaded lid on/off. These were done on the CNC, they could be done on a threading jig with a little hand clean up, but nobody makes threading jigs with this coarse of a pitch.

View attachment 47725