Yesterday, I received the Ashley Harwood BOB gouge that I had ordered. I must say it's an impressive piece of equipment. VERY sturdy, 3/4" diameter, with a shorter flute, all designed to reduce vibration. $140 including shipping for an unhandled gouge. I'm fine with all that, and am looking forward to using it. But I have some questions. While I was waiting for it, I emailed Harwood and asked her for information on sharpening and using it. After a few days she responded with a link to a video course she is selling for $90, and told me there would be information in there. I have to pay $90 for just a little help on use of a fairly expensive tool???? The gouge actually has 3 bevels (see picture), one of them steeper than any other BOB gouge I have owned or used. Harwood claimed, somewhere, that her design eliminates the "kick" that usually comes when first starting a cut. I have not yet measured the angles on the bevels. Does anyone here have experience with this gouge? If so, could you supply the help that Ashley wouldn't? Thanks, Russ

-

December 2025 Turning Challenge: Single Tree! (click here for details) -

Congratulations to Bob Henrickson, People's Choice in the November 2025 Turning Challenge (click here for details) -

Congratulations to Guillaume Fontaine for "Old Tea Pot" being selected as Turning of the Week for December 15, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ashley Harwood Bottom Of The Bowl Gouge

- Thread starter Russell Karkheck

- Start date

Looks like you could do that like sharpening a spindle roughing gouge but after your done with 1 bevel, move it to the next.

Thanks, Carl. I agree. But it would also be helpful to know what the target is, in case I mess it up sometime in the future.Looks like you could do that like sharpening a spindle roughing gouge but after your done with 1 bevel, move it to the next.

Tom Gall

TOTW Team

Measure the shortest bevel now (cutting edge) for reference. The other two are just clearance angles and don't really matter. You may want to change the cutting bevel later - after some use, to your own preference. You can always go back to the original grind.Thanks, Carl. I agree. But it would also be helpful to know what the target is, in case I mess it up sometime in the future.

Sorry that you had to experience that poor customer service. I am very surprised. This is an aberration in our community. Most woodturning vendors bend over backward to answer any questions about their products.Yesterday, I received the Ashley Harwood BOB gouge that I had ordered. I must say it's an impressive piece of equipment. VERY sturdy, 3/4" diameter, with a shorter flute, all designed to reduce vibration. $140 including shipping for an unhandled gouge. I'm fine with all that, and am looking forward to using it. But I have some questions. While I was waiting for it, I emailed Harwood and asked her for information on sharpening and using it. After a few days she responded with a link to a video course she is selling for $90, and told me there would be information in there. I have to pay $90 for just a little help on use of a fairly expensive tool???? The gouge actually has 3 bevels (see picture), one of them steeper than any other BOB gouge I have owned or used. Harwood claimed, somewhere, that her design eliminates the "kick" that usually comes when first starting a cut. I have not yet measured the angles on the bevels. Does anyone here have experience with this gouge? If so, could you supply the help that Ashley wouldn't? Thanks, Russ

From everything posted about BOB gouges, seems like most are ground to 80 or 85 degrees.

I made one out of an old bowl gouge. Works just fine with one bevel.

I made one out of an old bowl gouge. Works just fine with one bevel.

I think mine is at 65 or 70 degrees. I have to remeasure every time I go to use it. My recollection is that Stuart recommend anywhere between 60 and 80. Sorry I don't have any proper references at hand. I'm sure with a little google you can find videos by Stuart, Sam Angelo, and Kent Weakley discussing BOB grinds.

I found this on her web site:

This 3/4" diameter bottom bowl gouge is made from M2 steel. It is 15” long, rather than the standard 12” long gouges to allow for deeper bowl turning. It has a short flute in order to minimize vibration when a significant amount of the tool is hanging off of the tool rest while working on larger pieces.

It cuts across the inside of the bottom of a bowl or across the face of a platter.

This tool has a small U-shaped flute. The wings are swept back by about 5 degrees, and it has approximately a 50 degree bevel angle.

This 3/4" diameter bottom bowl gouge is made from M2 steel. It is 15” long, rather than the standard 12” long gouges to allow for deeper bowl turning. It has a short flute in order to minimize vibration when a significant amount of the tool is hanging off of the tool rest while working on larger pieces.

It cuts across the inside of the bottom of a bowl or across the face of a platter.

This tool has a small U-shaped flute. The wings are swept back by about 5 degrees, and it has approximately a 50 degree bevel angle.

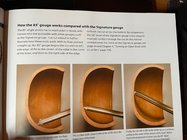

I would like to see a video of you using a bottom bowl gouge with 85 degrees bevel. I find it, and most professionals do too, unusable, very grabby. Stuart Batty has his at 60 degrees for bowls and 50 for platters. In calabashes, I use both. Ashley is, like me, one of the 8th Stuart Batty apprentices. She would have hers at 60 degrees. The other bevels are not that important. The second one is there so you can quickly change from 60 to 50. Because is a very short bevel, you can change the angle in seconds. The 3rd secondary bevel is there so you don't bruise the wood with the heel. My hat is off to you if you can leave a glossy surface with an 85 degrees bevel, Stuart and I find it impossible to use. I do not like to fight with a bowl gouge, I want her to work for me. @Russell Karkheck no charge for this info, LOLFrom everything posted about BOB gouges, seems like most are ground to 80 or 85 degrees.

I made one out of an old bowl gouge. Works just fine with one bevel.

The Thompson BOB comes ground at about 70 degree bevel and it is 3/4" single bevel 10V steel. My personal BOB is a 3/8" Thompson U gouge with a 80 degree single bevel and I only use it on wood where the tear out at the transition from the side to the bottom occurs that I cannot clear any other way. With either of these tools I get no bruising of the wood because of the heal of the tool.

john lucas

AAW Forum Expert

I still prefer my Hunter Badger. It has an 82 degree outside bevel but a cutting edge of 60 degrees. So it cuts across the bottom of a steep sided bowl but leaves a cleaner cut.

I have BOB gouges....and shiver a little when I have to grab one of them. I think I will try the Badger John. Thanks for reminding us of that option.I still prefer my Hunter Badger. It has an 82 degree outside bevel but a cutting edge of 60 degrees. So it cuts across the bottom of a steep sided bowl but leaves a cleaner cut.

honestly...this does not surprise me with Ashley.I have to pay $90 for just a little help on use of a fairly expensive tool????

That is why I buy ALL of my tools from Doug Thompson...he sells the tools and supports them at no additional cost.

Sorry for advertising...but that is my experience.

And I use and love Doug BOB Gouge all the time.

Just curious…. Why the “ anti-Ashley” timbre in th thread? I can easily find fault with any presenter/ professional…. But prefer not to.

Sounds like a nice tool and poor customer service. Who needs it! So many excellent tools around with great support from the makers.

I'd say the customer service is fine, it's just the cost of it. Quite non-traditional to charge for sharpening instructions. On the other hand we have all learned to take a Sharpie and color the bevel to position the tool for sharpening. I can't see a minor error of one or two degrees causing the gouge to not work. Can't say I would be pleased to spend that much for gouge at this stage of my work. Probably would have as a newer turner, but not now. We all know that making a living at turning comes in many different paths.

Last edited:

The woodturning community is relatively small.Just curious…. Why the “ anti-Ashley” timbre in th thread? I can easily find fault with any presenter/ professional…. But prefer not to.

It seems most turners know the demonstrators and vendors on some level. (symposiums, club demos, connected on Facebook, this forum, etc.)

It is unusual in this community for someone to ask a simple question and get a response of "I'll tell you for $90"...especially when the question is about a product you just purchased from that person.

I think that business model hurts this community which tends to be very open and helpful to each other.

- Joined

- Apr 27, 2004

- Messages

- 9,307

- Likes

- 6,074

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

This is a tough one.While I was waiting for it, I emailed Harwood and asked her for information on sharpening and using it. After a few days she responded with a link to a video course she is selling for $90, and told me there would be information in there.

From one perspective you received a solution to your problem.

From another perspective your simple request was ignored.

If I were a vendor I would happily give a customer five minutes of my time to teach them how to sharpen the gouge.

I would not be willing to give them 30 minutes or 2 hours.

I suspect you need something in between.

When I teach sharpening I demonstrate and then stand at the grinder as each student sharpens.

With demos, and watching each student get about 30 minutes of my time.

First thing they sharpen is a round nose scraper, then the bowl gouge with a jig.

On the bowl gouge I turn the grinder off as they start.

I teach The SRG two ways.

Basic put it on the platform, adjust the platform angle to match the bevel, hold the tool on the platform, roll the tool wing to wing.

Advanced rest hand on the platform, use thumb and forefinger to hold the bevel against the wheel, roll the tool wing to wing.

Emiliano - I'm a believer that everyone should use whatever grind they are comfortable with as everyone has their own opinions of what works best for them and I don't judge who's right or who's wrong. I was taught using a bowl gouge with a 55 or 60 degree bevel angle. I prefer my gouges with swept back wings. I would say I use this grind for 99% of the bowls I make. I know you are a disciple of Stuart Batty, but I admit I've never tried the 40/40 since I haven't seen the need to invest the time, money or energy.I would like to see a video of you using a bottom bowl gouge with 85 degrees bevel. I find it, and most professionals do too, unusable, very grabby. Stuart Batty has his at 60 degrees for bowls and 50 for platters. In calabashes, I use both. Ashley is, like me, one of the 8th Stuart Batty apprentices. She would have hers at 60 degrees. The other bevels are not that important. The second one is there so you can quickly change from 60 to 50. Because is a very short bevel, you can change the angle in seconds. The 3rd secondary bevel is there so you don't bruise the wood with the heel. My hat is off to you if you can leave a glossy surface with an 85 degrees bevel, Stuart and I find it impossible to use. I do not like to fight with a bowl gouge, I want her to work for me. @Russell Karkheck no charge for this info, LOL

Since my gouges are already at 60 degrees there's no need to "buy" a BOB gouge that some folks are selling with 60 degree bevels. My advice would be if all you have is 40/40 bowl gouges go buy any bowl gouge at 60 degrees and try as a BOB, plus (!) you might just find the same tool works for 99% of the bowls you make. My BOB gouge is used maybe on 1 out of 100 bowls. Those that are way deeper than wide (or deep with a narrow top opening) and I just can't get the 60 degree bevel to ride properly

I fashioned my BOB grind from David Ellsworth's book "Ellsworth on Woodturning". Ellsworth's book is an excellent resource in addition to the Raffan books I have. On pages 32, 33, 34 and 35 Mr. Ellsworth talks about his BOB gouges at 85 degrees which I tried to emulate, but, I don't get too hung-up on exactly what bevel angle I use. I ground mine similar to the top gouge in the photo below. In response to your comment "I would like to see a video of you using a bottom bowl gouge with 85 degrees bevel. I find it, and most professionals do too, unusable, very grabby" I don't have a video I can show you how it works, but it's possible Mr. Ellsworth has some videos up somewhere if you want to see it in action. Just sayin'

Attachments

Last edited:

I agree...we spend a lot of time talking about angles. But we are all different heights and are comfortable holding our tools differently. Grind your tools so the are presented to the wood BY YOU at an angle that gets the edge where it needs to be to CUT and not catch. The wood doesn't know if it is 60 degrees or 62 degrees....or 65 degrees for that matter.but, I don't get too hung-up on exactly what bevel angle I use.

I honestly don't know the angles of my grinds (I know how they started)...but I found what is comfortable FOR ME and have set my jigs to replicate that.

Thanks for the *free* advice, Emiliano!I would like to see a video of you using a bottom bowl gouge with 85 degrees bevel. I find it, and most professionals do too, unusable, very grabby. Stuart Batty has his at 60 degrees for bowls and 50 for platters. In calabashes, I use both. Ashley is, like me, one of the 8th Stuart Batty apprentices. She would have hers at 60 degrees. The other bevels are not that important. The second one is there so you can quickly change from 60 to 50. Because is a very short bevel, you can change the angle in seconds. The 3rd secondary bevel is there so you don't bruise the wood with the heel. My hat is off to you if you can leave a glossy surface with an 85 degrees bevel, Stuart and I find it impossible to use. I do not like to fight with a bowl gouge, I want her to work for me. @Russell Karkheck no charge for this info, LOL

I have a bunch of different BOB tools, from half round flutes, to spindle detail type gouges, to U flutes, and some of Doug's fluteless gouges. I use them all. For me, mine are all ground to 70 degree bevels, and I relieve at least half of the bevel. I do this by freehanding it and rolling it around so there are no sharp edges. I did try a couple of them that were ground more straight across the top, similar to what Ashley's gouge is, which is also similar to a SRG. Didn't like that one because that square edge would tend to dig in and catch with starting hear the little steps that we tend to leave in the bottom of the bowls, which is more common with with the 40/40 grind gouge users than the 60 degree gouge users. Mine are all ground to about a 40 degree sweep to the side, so the nose profile is ) shaped. It is less prone to digging in with that low side corner/edge, but it still can do that. I always ease in to that cut.

I do have a couple of 60 degree ones that I use, with very similar nose profiles. Over the years, I still prefer the 40/40 for the bowl walls, and switch to a BOB tool for the transition and the bottom of the bowl. If for no other reason, if you are turning bowls, with a 60 degree bevel, on a long bed lathe, or don't slide your headstock down, you have to extend your arms out farther away from your body to make the cuts down the inside wall. Pretty much the same for the outside walls too. I always slide my headstock down to the end so this is not an issue for me.

I do think Ashley should have responded to you with some thing other than "take my $90 class".

robo hippy

I do have a couple of 60 degree ones that I use, with very similar nose profiles. Over the years, I still prefer the 40/40 for the bowl walls, and switch to a BOB tool for the transition and the bottom of the bowl. If for no other reason, if you are turning bowls, with a 60 degree bevel, on a long bed lathe, or don't slide your headstock down, you have to extend your arms out farther away from your body to make the cuts down the inside wall. Pretty much the same for the outside walls too. I always slide my headstock down to the end so this is not an issue for me.

I do think Ashley should have responded to you with some thing other than "take my $90 class".

robo hippy

A few years ago I bought a crown 1/2" BOB gouge and tried to use it. Every once in a while I could hit the sweet spot a make a bottom smooth as glass, others times it would leave a trail of swirls. I'm going to grind it to the specs Ashley has on her website. That's the information I listed above. She has a little presentation on her website where she uses her big gouge on the bottom of a bowl. I do not nor plan to see how far away from the bowl I can put my rest and safely turn. I put my rest up in the bowl to hollow and shape as far as I can. My gouge is smaller than hers but the cutting principle is the same, would like to put this tool to regular use. I believe the crown gouge came with an 80 degree bevel, but the whole cutting edge is swept maybe 10 degrees.

- Joined

- Jul 18, 2018

- Messages

- 1,345

- Likes

- 2,911

- Location

- Baltimore, MD

- Website

- loujacobswoodturning.com

I’d just like to point out that according to Russell, this was an email communication. I’ve learned through hard and sometimes painful experience that it is dangerous to react to quickly to something when I’ve heard only one side, or just a snippet of a conversation, particularly if it was digital rather than live person to person. I’d cut Ashley some slack and wonder if she thought she could answer Russell most effectively by referring him to a detailed demo she’s created. She may have misunderstood the detail of a response Russell was requesting, or just been swamped at the moment and thought she was getting a problem effectively out of her inbox. Perhaps Russell, give her a chance by following up with your more specific question? Just my $.02.While I was waiting for it, I emailed Harwood and asked her for information on sharpening and using it. After a few days she responded with a link to a video course she is selling for $90, and told me there would be information in there.

Not to belabor the point… bit the $90 is not just how to sharpen. It is a complete syllabus of claases… a course on woodturning.

When I e-mailed her a question she answered it as well as recommended her course on woodturning. Fair enough. My gut says that would be her normal kind of response. She is a strong marketer and some will find that off-putting. I suppose it equals the off-put feeling I have for other professionals whose egos give them permission to profunderate on how their method is the only way to do things.

The human condition we all suffer is one replete with flaws…. and lack of humility

When I e-mailed her a question she answered it as well as recommended her course on woodturning. Fair enough. My gut says that would be her normal kind of response. She is a strong marketer and some will find that off-putting. I suppose it equals the off-put feeling I have for other professionals whose egos give them permission to profunderate on how their method is the only way to do things.

The human condition we all suffer is one replete with flaws…. and lack of humility

Russell - I mention it above that I have David Ellsworth's book, "Ellsworth on Woodturning", which was helpful to me with some great advice. Nothing like learning from one of the best. I know it's another expense to purchase the book, but Ellsworth goes into some detail about how to present the BOB gouge for effective cutting action. Small excerpt in photo. Good luck to you.Thanks for the *free* advice, Emiliano!So let's see whether I can get more advice from you.

When I spent 5 days studying with Stu, he taught me to sharpen the BOB gouge first at 40 degrees. Then put your finger under the gouge on the platform to lift it up and grind the primary bevel That has worked fine for me. So the sharpening issue wasn't the biggest concern. I've never been comfortable with my understanding of how to present the gouge. Do I use it with the flute at 12 o'clock, 1 o'clock, at one position and rotating as I go down the side, etc.? I think that, like sharpening, could have been answered in a couple of sentences. I'm glad to hear that others found that lack of communication from the vendor unusual, as did I. I'm not looking to hate on Ashley Harwood. Just think she was unexpectedly stingy and more interested in marketing than taking a few seconds to help - especially after someone has bought her tool. As I said before, I'm impressed with how well-made that gouge is. Thanks to all who have responded.

Attachments

Thanks, John! I do, indeed, have Ellsworth's book, but haven't read it in a very long time. In fact, my first introduction to the BOB was in a 3 day seminar at his house/workshop some years back. But I didn't actually get one of those gouges until after I began using (and loving) the 40/40 when I did 5 days studying with Batty. That was 3-4 years ago, so I have forgotten some stuff. Time for a tune-up when Stu gets his new facility up and running. I AM looking forward to seeing him Saturday and Sunday at Totally Turning. I really appreciate your taking the time to help me. RussRussell - I mention it above that I have David Ellsworth's book, "Ellsworth on Woodturning", which was helpful to me with some great advice. Nothing like learning from one of the best. I know it's another expense to purchase the book, but Ellsworth goes into some detail about how to present the BOB gouge for effective cutting action. Small excerpt in photo. Good luck to you.

Last edited:

Angelo

President Emeritus

- Joined

- Jun 14, 2004

- Messages

- 430

- Likes

- 182

- Location

- Lancaster, Pennsylvania

- Website

- www.majicbrand.com

Yah.Emiliano - I'm a believer that everyone should use whatever grind they are comfortable with as everyone has their own opinions of what works best for them and I don't judge who's right or who's wrong. I was taught using a bowl gouge with a 55 or 60 degree bevel angle. I prefer my gouges with swept back wings. I would say I use this grind for 99% of the bowls I make. I know you are a disciple of Stuart Batty, but I admit I've never tried the 40/40 since I haven't seen the need to invest the time, money or energy.

Since my gouges are already at 60 degrees there's no need to "buy" a BOB gouge that some folks are selling with 60 degree bevels. My advice would be if all you have is 40/40 bowl gouges go buy any bowl gouge at 60 degrees and try as a BOB, plus (!) you might just find the same tool works for 99% of the bowls you make. My BOB gouge is used maybe on 1 out of 100 bowls. Those that are way deeper than wide (or deep with a narrow top opening) and I just can't get the 60 degree bevel to ride properly

I fashioned my BOB grind from David Ellsworth's book "Ellsworth on Woodturning". Ellsworth's book is an excellent resource in addition to the Raffan books I have. On pages 32, 33, 34 and 35 Mr. Ellsworth talks about his BOB gouges at 85 degrees which I tried to emulate, but, I don't get too hung-up on exactly what bevel angle I use. I ground mine similar to the top gouge in the photo below. In response to your comment "I would like to see a video of you using a bottom bowl gouge with 85 degrees bevel. I find it, and most professionals do too, unusable, very grabby" I don't have a video I can show you how it works, but it's possible Mr. Ellsworth has some videos up somewhere if you want to see it in action. Just sayin'

I, too, use an "Ellsworth" style grind. I learned about it at the Purchase NY Symposium (1993 I think). I'm sue, after all these years I've strayed away from the perfect Ellsworth grind. Then we called it an "Irish" grind because Liam O'Neil claimed to have invented it. At the same time David Ellsworth claimed the same. At any rate with this grind you are able to make a single finishing cut from the rim to the bottom without using a bottom bowl gouge.

I did buy a Carter Bottom Gouge and a Thompson Bottom Gouge to see for myself what all the hype was about. I sold the Carter Bottom Gouge and the I may sell off the Thompson as I find that David Ellsworth's grind works as advertised with one less tool.

Angelo

President Emeritus

- Joined

- Jun 14, 2004

- Messages

- 430

- Likes

- 182

- Location

- Lancaster, Pennsylvania

- Website

- www.majicbrand.com

Oh! BTW take a look at Richard Raffan's You Tube video to see how he sharpens his bowl gouges. It's an ASYMMETRIC grind! I will try this grind on one of my bowl gouges.....just to see for myself

Russell, the 40 degrees is for the bowl gouge. The bottom bowl gouge has a bit of a learning curve. I believe mainly because you have to let her do the work by not holding it like a regular gouge. Most people have the tendency to want it to guide it and hold it like an Ellsworth gouge. The flute should be around 12 to 1, like you said. Moving it above center in an arc, coming down right at center, then you slow it down so you do not tear up the center. You can do an entire bowl with a 60 degree Ellsworth gouge, I have about 3 of them, including one that I traded Koa for a 5/8 gouge with David. The 60 degree is much easier to control than an 80 or 85. That would $1, payable thru PayPal, LOLThanks for the *free* advice, Emiliano!So let's see whether I can get more advice from you.

When I spent 5 days studying with Stu, he taught me to sharpen the BOB gouge first at 40 degrees. Then put your finger under the gouge on the platform to lift it up and grind the primary bevel That has worked fine for me. So the sharpening issue wasn't the biggest concern. I've never been comfortable with my understanding of how to present the gouge. Do I use it with the flute at 12 o'clock, 1 o'clock, at one position and rotating as I go down the side, etc.? I think that, like sharpening, could have been answered in a couple of sentences. I'm glad to hear that others found that lack of communication from the vendor unusual, as did I. I'm not looking to hate on Ashley Harwood. Just think she was unexpectedly stingy and more interested in marketing than taking a few seconds to help - especially after someone has bought her tool. As I said before, I'm impressed with how well-made that gouge is. Thanks to all who have responded.

The only few times I have seen demonstrations about a bottom of the bowl gouge have been in conjunction with tear out at the transition of the side of the bowl to the bottom of the bowl. Normally I have no problem with any wood cutting with my Thompson gouge from top to bottom. I really have no idea what the angle I'm getting on my gouge from the Vector Grind fixture. I have never measured to my knowledge any tool until the other day in this thread where I measured a new Thompson BOB gouge. And again I only use my BOB when I have a very tough piece of wood that I get tear out in that area and it is for that area alone. That transition area on the inside of a bowl is the hardest thing to learn for a new turner whether its caused by heel rubbing or any myriad of things that is where they will get tear out and heel rubbing tear out is really hard to get rid of. Maybe one should look at a BOB side by side to a SRG, I can envision someone cutting with an 80 degree BOB and not holding it correctly getting into trouble.

Emiliano, that is EXACTLY what I was hoping to learn. Thank you! But I must disagree with you on one thing. I don't think your advice was worth $1.00. I think it's worth $3.00. The check is in the mail. Keep looking for it . . .Russell, the 40 degrees is for the bowl gouge. The bottom bowl gouge has a bit of a learning curve. I believe mainly because you have to let her do the work by not holding it like a regular gouge. Most people have the tendency to want it to guide it and hold it like an Ellsworth gouge. The flute should be around 12 to 1, like you said. Moving it above center in an arc, coming down right at center, then you slow it down so you do not tear up the center. You can do an entire bowl with a 60 degree Ellsworth gouge, I have about 3 of them, including one that I traded Koa for a 5/8 gouge with David. The 60 degree is much easier to control than an 80 or 85. That would $1, payable thru PayPal, LOL

Well, even with my half round and U flute BOB tools, I still have the tool up on its edge, so flutes sideways. As near as I can tell, this gives me a slightly higher shear angle for the cut. For sure when using the spindle detail flutes and the fluteless gouge, I keep the tool at a 45 to maybe 70 or more degree angle. Same reason, a higher shear angle, or maybe that is a slicing angle.

The nice thing about sharpening is that mistakes can be undone. As you've heard, there's more than one angle that works, and you certainly can replicate what the gouge came with. $140 seems expensive for an M2 tool, IMHO, but maybe she has an exclusive on that design? My BOB gouges are made from short (worn down) 5/8" gouges, obviously not as wide but a nice short flute.

Bill, your post brings me to an issue dear to my heart: open bowl forms for newbies. First of all, they learn to glide a long, smooth (eventually) path from top to bottom. A bowl that has a sharp transition or, heaven forbid, is too enclosed (deep, but too-small diameter) causes problems. The diameter-to-depth ratio can be such that it's impossible to go through the transition without having the handle meet the rim which prevents the bevel from maintaining contact with the wood - - major tear-out. The higher the tool bevel angle, the easier it is to avoid that problem, but 45 works fine on open forms. If I remember right, I used a BOB the first time when turning a Dublin Viking Bowl with Glenn Lucas. "Enclosed form" for sure. BOB's are great for platters, and (speaking of roughing gouges) Schweitzer uses his D-Way roughing gouge on platters sometimes, only because it has a round tang which is strong. The angle works well.The only few times I have seen demonstrations about a bottom of the bowl gouge have been in conjunction with tear out at the transition of the side of the bowl to the bottom of the bowl. Normally I have no problem with any wood cutting with my Thompson gouge from top to bottom. I really have no idea what the angle I'm getting on my gouge from the Vector Grind fixture. I have never measured to my knowledge any tool until the other day in this thread where I measured a new Thompson BOB gouge. And again I only use my BOB when I have a very tough piece of wood that I get tear out in that area and it is for that area alone. That transition area on the inside of a bowl is the hardest thing to learn for a new turner whether its caused by heel rubbing or any myriad of things that is where they will get tear out and heel rubbing tear out is really hard to get rid of. Maybe one should look at a BOB side by side to a SRG, I can envision someone cutting with an 80 degree BOB and not holding it correctly getting into trouble.

Are large sharpening angles (as on a BOB gouge) inherently better for platters and bowl bottoms? As a cabinetmaker that makes sense to me - low rake (attack) angles work better on figured woods where you are cutting into end grain on a flat surface, whereas high rake angles work better at slicing across end grain. BOB gouges are sometimes said to be needed only for maintaining bevel contact in a steep-sided bowl, but is there more to it?

This. (At least that's my understanding).BOB gouges aresometimes said to beneeded only for maintaining bevel contact in a steep-sided bowl,

Thanks, Tim, (and others who have) for sticking up for the professional. It's not usually ego that leads a person to do strong marketing, it's the need to make a living. Remember that Ashley is not of retirement age yet, and does not approach woodturning as a hobby. She is not living on Social Security or a pension. This is her business, her "job". A business doesn't thrive without marketing. Or a good reputation. She is doing what she thinks will work, and may occasionally make a mistake. We are also making a mistake when we think a person who is working for a living should give away everything they do. A balance is necessary. We are only hearing one side, here, as someone else pointed out, and from her side it might look different. Let's give her a break!Not to belabor the point… bit the $90 is not just how to sharpen. It is a complete syllabus of claases… a course on woodturning.

When I e-mailed her a question she answered it as well as recommended her course on woodturning. Fair enough. My gut says that would be her normal kind of response. She is a strong marketer and some will find that off-putting. I suppose it equals the off-put feeling I have for other professionals whose egos give them permission to profunderate on how their method is the only way to do things.

The human condition we all suffer is one replete with flaws…. and lack of humility

Thank you Cindy for your post. I try to keep an open mind as I cannot see the whole picture from my position "at the lathe". My perspective is that I want to learn at least one thing from everyone I meet. Some can teach me much more. But no one person can know everything. So, if I allow a personality, or a method of hoe someone approaches the market to interfere with my ability to actually learn from the person teaching....I lose. Just as with the T.V. - I can always change the channel if I am so compelled.

My perspective is that I want to learn at least one thing from everyone I meet. Some can teach me much more. But no one person can know everything. So, if I allow a personality, or a method of hoe someone approaches the market to interfere with my ability to actually learn from the person teaching....I lose. Just as with the T.V. - I can always change the channel if I am so compelled.

T

T

Last edited:

Cindy,Thanks, Tim, (and others who have) for sticking up for the professional. It's not usually ego that leads a person to do strong marketing, it's the need to make a living. Remember that Ashley is not of retirement age yet, and does not approach woodturning as a hobby. She is not living on Social Security or a pension. This is her business, her "job". A business doesn't thrive without marketing. Or a good reputation. She is doing what she thinks will work, and may occasionally make a mistake. We are also making a mistake when we think a person who is working for a living should give away everything they do. A balance is necessary. We are only hearing one side, here, as someone else pointed out, and from her side it might look different. Let's give her a break!

I agree everyone is entitled (and should) make a living...and professionals should not give anything away (I get paid for the pieces I sell and when I demo...contact me directly for more information

But I think the original question here was about having purchased a tool, and then asking about how to sharpen the tool. When I purchase a car, I expect the dealer to tell me where the gas goes, and what the maintenance should be. When I buy most items I get some use and care instructions. When I buy a tool...if I have a question about sharpening (what angle is currently ground so I can maintain it?) I would expect that answer to be included in the purchase.

If I want lessons on how to turn a bowl because I just bought my 1st bowl gouge....I'd expect to pay for those lessons.

As you said....Balance.