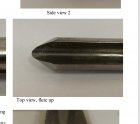

The so-called “40/40 grind” (or sometimes “45/45 grind”) has received quite a bit of attention lately. It is usually described as a platform grind in which the platform is set to produce a nose angle of 40 (or 45) degrees and in which the sharpening involves swinging the gouge alternately 40 (or 45) degrees to the left and right of center while smoothly rotating the gouge on its axis such that the flute points approximately outwards at the end of each swing.

It occurred to me that this grind can be matched exactly at the nose and the outer points of the wings, at least, using a Varigrind jig. Furthermore, the grind will progress smoothly between these end points, whether or not it matches exactly that produced by direct hand rotation of the gouge. To achieve this, one merely needs to adjust the arm angle of the jig so that at the ends of the swings, the shaft of the gouge is at an angle of 40 (or 45) degrees with respect to an imaginary line between the pivot point of the jig and the tip of gouge. To achieve a 40-degree angle using a 1.75-inch gouge protrusion from the jig, open the arm angle half-way between the fifth and sixth notches. To achieve a 45-degree angle, set the arm angle half-way between the sixth and seventh notches. Small variations from the 1.75-inch protrusion would have negligible effect on the required arm settings.

Bear in mind that, as in all free-hand or jig-aided sharpening approaches, the results obtained depend only in part on the rules followed or the jig settings used. How long you grind and where you grind will determine the final result.

It occurred to me that this grind can be matched exactly at the nose and the outer points of the wings, at least, using a Varigrind jig. Furthermore, the grind will progress smoothly between these end points, whether or not it matches exactly that produced by direct hand rotation of the gouge. To achieve this, one merely needs to adjust the arm angle of the jig so that at the ends of the swings, the shaft of the gouge is at an angle of 40 (or 45) degrees with respect to an imaginary line between the pivot point of the jig and the tip of gouge. To achieve a 40-degree angle using a 1.75-inch gouge protrusion from the jig, open the arm angle half-way between the fifth and sixth notches. To achieve a 45-degree angle, set the arm angle half-way between the sixth and seventh notches. Small variations from the 1.75-inch protrusion would have negligible effect on the required arm settings.

Bear in mind that, as in all free-hand or jig-aided sharpening approaches, the results obtained depend only in part on the rules followed or the jig settings used. How long you grind and where you grind will determine the final result.