Tapping a tool on the rest? I, too, have never done that, nor thought to do it. Wondering why, about the only reason I can think of to do so would be to clear shavings from the flute of a bowl gouge (flute aimed down), and the top edges of the flute of a hardened steel bowl gouge make for one of the very best "distressing" implements for cast iron that I can think of. There could be thousands of psi equivalent at that very small contact point from that innocent tap/whack. But if I have that situation, I've always mindlessly, in about a half second flat, run a fingertip (handle toward edge) down the flute to clear it. Yeah, willingly banging hardened steel on cast iron is not a good idea.

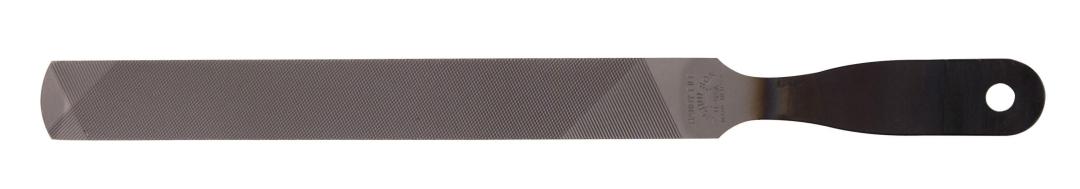

Up until just this past year when I bought 2 Robust rests for my now one year old Oneway 1224 (I didn't care for the OEM rests), I've never had an issue with using cast iron tool rests, my big lathes and small. All my tools with sharp corners (parting tools, skews, etc.) saw time on grinding wheels or sanding belts to round and smooth the corners. But an occasional ding would happen on the rest and for that I kept a fine single-cut mill file right at the lathe. A few full length strokes down the length of the rest, and I'm back to work. Non-issue for this hobby turner.

Hardened steel top tool rests are... great... good... just fine... yeah, just fine, but I've never wished for one if the factory cast iron rest was comfortable for me to use.