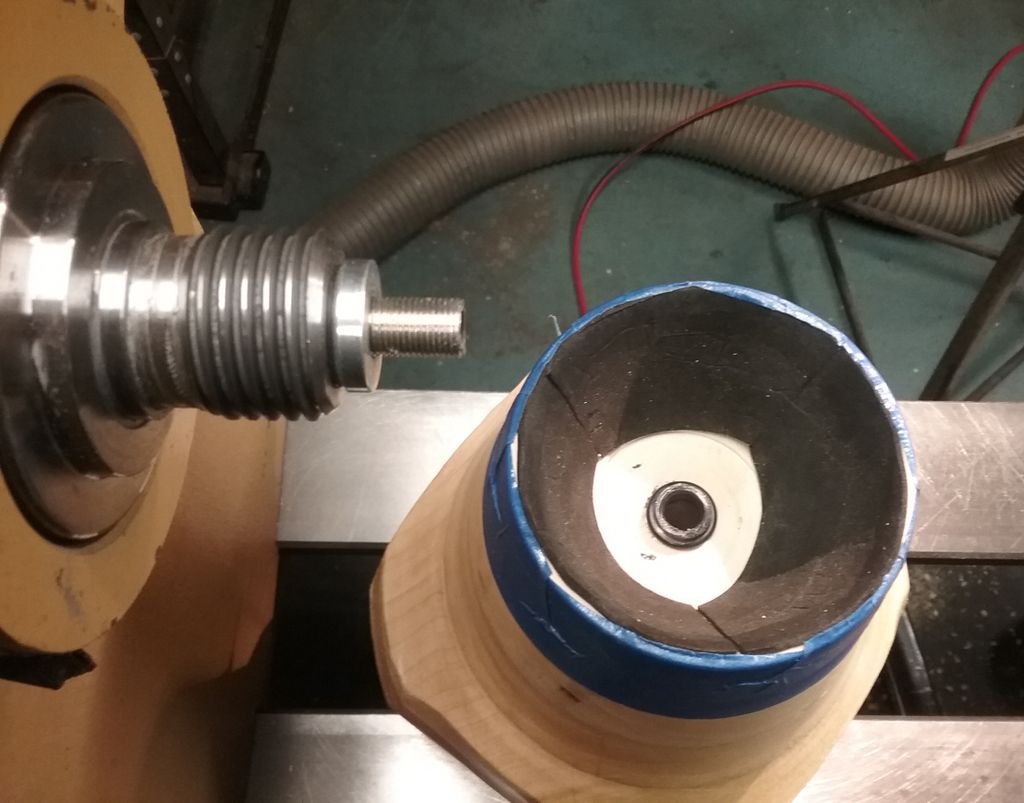

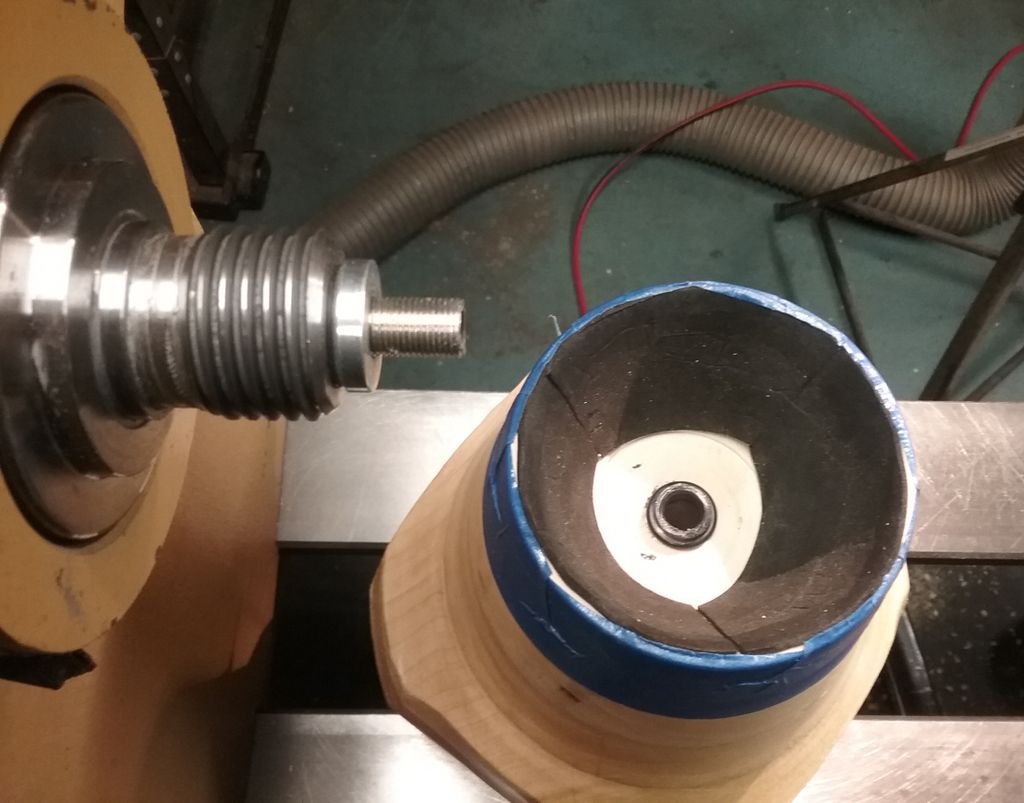

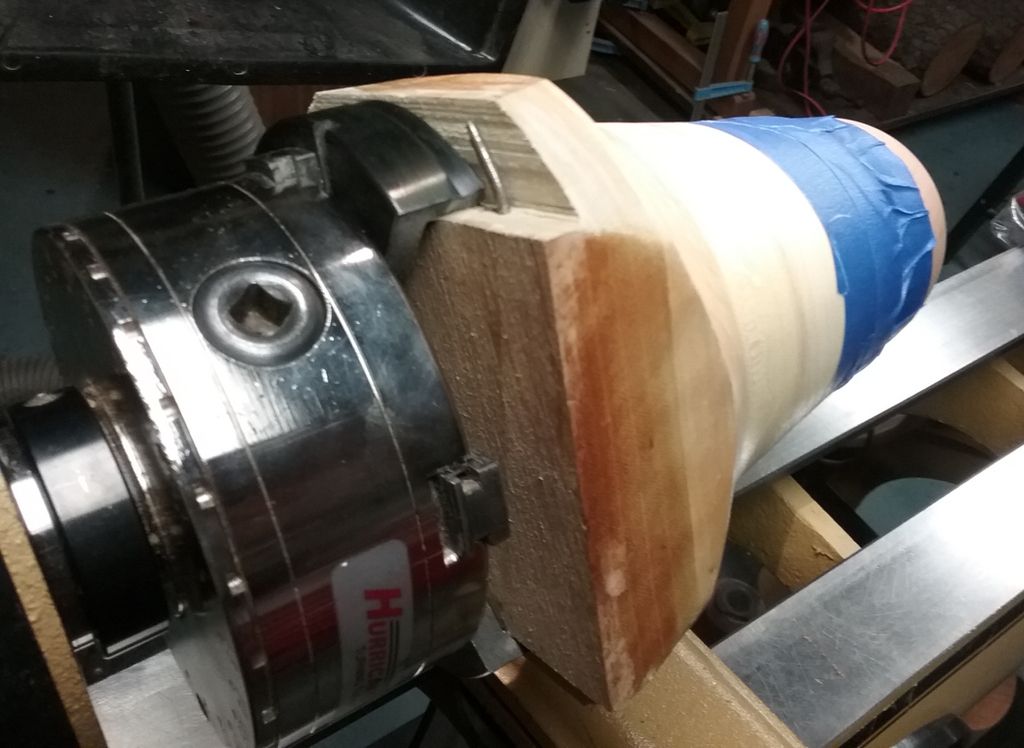

Had a chance to add vacuum to this 1st generation sliding eccentric sphere chuck today. Had been just adding blue tape to hold the sphere in place and although the tape seems to work just fine by itself, decided to add the vacuum for a little extra piece of mind and security. Fashioned after David Reed Smith's instructions, kind of happy with the results. Just used materials that were already on hand (except for the tubing), so it's a little bigger than the next would be if I want to try something different. As stated, this is made so the incision offset can be variable by sliding different distances off center, Can always return to center with a cut-off nail serving as a zero point. I think I'll use contrasting color inlays for these first few that I've done, like the light blue colored inlay in the cherry sphere in the last picture.