So if taking a raw log to finished bowl typically requires first turning it green to a rough size and then again after drying and warping to a final shape… with sanding and finishing… does this also apply to hollow forms? The way I understand it, hollow forms are typically turned from green wood to a wall thickness of 1/4” or less in one turning. While this thickness most likely wouldn’t cause cracking, the piece will most definitely warp while drying and would seem to cause out of round issues if mounted back on the lathe for sanding, finishing, embellishing etc. Are hollow forms that are turned green sanded and finished before allowing to dry (if that’s even a possibility)… or are they sanded and finished after drying? And if so, how?

-

April 2025 Turning Challenge: Turn an Egg! (click here for details) -

Congratulations to Kelly Shaw winner of the March 2025 Turning Challenge (click here for details) -

Congratulations to Ellen Starr for "Lotus Temple" being selected as Turning of the Week for 21 April, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Questions about Hollow Forms

- Thread starter John Johnson

- Start date

John, I have been turning hollow forms for close to 20 years now. There have been a few times that I have turned them to a finished condition in one cycle, but unless the wood is very dry, it will always be two cycles. My process is to rough turn the hollow form, triple bag it, (3 paper grocery bags), then place it on the shelve for between 6 months to a year. BUT I live in a low humidity area, I don't believe you do! If the humidity is an issue where you live, the time in storage will be longer, not less. My suggestion would be to contact a professional turner in your area, and ask for their input.

My turnings are not "organic", by that I mean natural warpage is not something I want. If the piece has voids, that's fine, I will decide if they are to be left natural or filled with epoxy or some other material on the second turning.

Don't waste your time sanding green wood to a "finished" state, you will be very unhappy in the end.

Just my two cents.

My turnings are not "organic", by that I mean natural warpage is not something I want. If the piece has voids, that's fine, I will decide if they are to be left natural or filled with epoxy or some other material on the second turning.

Don't waste your time sanding green wood to a "finished" state, you will be very unhappy in the end.

Just my two cents.

I've done hollow forms from dry wood, twice turned from green and once turned from green. If you want round and true you will have to have dry wood. Most of my once turned pieces have been burls, which may dry more symmetrically than normal wood. I usually sand green - that can leave a somewhat textured finish depending on the wood. To hold a dry once-turned piece for sanding, etc. you can use a chucking recess, take a chance on leaving the tenon, or turn away the tenon or glue block for drying and add a temporary one back with hot melt glue. I mostly sand with the lathe turning slowly or not at all so some eccentricity is not an issue.

I have done many hollow forms and yes it must be green wood unless it is segmented such as my avatar. I have never done a once turned hollow form since that is what it would have to be with 1/4" walls. The wall thickness on a miniature at say 3" dimeter X 6" high might work with about 1/2" wall thickness and getting thicker as they get larger, but the main rule is to have a uniform wall thickness. One way to reduce distortion is to use the full round with the pith completely removed on the top and a base as small as possible with the pith centered.

- Joined

- Apr 27, 2004

- Messages

- 9,161

- Likes

- 5,762

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

piece will most definitely warp while drying and would seem to cause out of round issues if mounted back on the lathe for sanding, finishing, embellishing etc. Are hollow forms that are turned green sanded and finished before allowing to dry

I turn hollowforms mostly facegrain from green wood. They warp. Most get oval. Burls stay close to round.

I finish turn them in one session. Dry them for 3-4 days.

I sand off the lathe using 3” Velcro pads on an angle drill.

The vast majority of hollow form turners do something similar.

Some people double-turn hollow forms. Not much fun to hollow a dried form so some of these only return the outside.

Also really tough on larger forms mine are up to 17” diameter. Most run 10-14” diameter.

You can do it either way. I wouldn’t do twice turned hollowforms because the once turned ones work out so well for me.

You might be interested in slides I show when I demo natural edge hollowforms. Every finished pieces is once turned.

Last edited:

Every pro turner demonstrating hollow forms that I've heard says they turn green wood. Maybe adding, "90% of the time".

All of my hollow forms are made with dry wood or a combination of dry wood and resin.

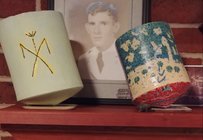

If the width is 2x or larger than the hollowing hole the hf tends to hold its shape. I followed JJ's creed of turning place in chest of drawers for 5-6 days then sand. Even the calabash zia series tend to hold their shape compared to bowls. The shape supports the vessels form. Turned endgrain.

Attachments

Last edited:

john lucas

AAW Forum Expert

Ii turn green hollow forms thin and put them in a cabinet or paper sack to dry. Usually takes just 2 weeks or so. I sand on or off the lathe at very low speed depending on how I hold the work.

Thanks for all the great responses everyone... it really helped to put things into perspective. I've got quite a bit of red oak from a tree that my neighbor had taken down and while I know it's not the greatest wood for turning... it was free and it's got some really nice grain patterns. I'm completely fine with any warping that may occur in drying. I've included some pics of a hollow form that I recently made that was turned to shape, sanded green with 80 grit and and then left to dry and warp for a few weeks and then sandblasted and colored with India Ink. I was planning on making a few more hollow forms with this wood and trying to enhance the grain even more with embellishing waxes. I just know it may be difficult to try and buff in a wax on an out of round warped vessel.

- Joined

- Apr 27, 2004

- Messages

- 9,161

- Likes

- 5,762

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

just know it may be difficult to try and buff in a wax on an out of round warped vessel.

Nice piece!

You might consider using a buffing wheel.

Easy to use on out of round pieces. You will want to use a dedicated wheel for each color of wax.

Another nice effect is achievable with milk paint.

This piece was sandblasted with resists. Blue milk paint the black milk paint.

Cut back with scotch bright. The red is the Sapele reaction with the milk paint.

All of my Hfs are twice turned from green wood to a wall thickness of 1/2". Once the first turning is done, I coat the entire outside with anchor seal to slow the drying process, and hang to dry. It usually takes about three months for the weight to stabilize in my environment. I take the wall thickness down to 3/16" or 1/4" during the second turning, and will smooth out the interior with my hollowing apparatus. I then sand and apply finish with the piece still mounted on the lathe. The final part of the process is to part the piece, sand and sign the bottom, and wipe on some finish on the bottom.

Do you thin the wall by removing material principally from the outside, or do you remove some from the inside as well?I take the wall thickness down to 3/16" or 1/4" during the second turning, and will smooth out the interior with my hollowing apparatus.

Thank you... and a very nice piece yourself!Nice piece!

You might consider using a buffing wheel.

Easy to use on out of round pieces. You will want to use a dedicated wheel for each color of wax.

Another nice effect is achievable with milk paint.

This piece was sandblasted with resists. Blue milk paint the black milk paint.

Cut back with scotch bright. The red is the Sapele reaction with the milk paint.

View attachment 42877

Good idea with the buffing wheels... i'll definitely look into them as they seem to be cheap enough to have one for every color.

I just received my resist material in the mail yesterday so I'll be experimenting with that as well...

Thanks again

@Mark Jundanian - during the second turning, I remove from the outside only what's needed to get the HF back into round. The amount that comes off varies, depending on how out-of-round the piece becomes while drying. I try and leave as much as possible on the outside so that I have enough wall thickness to get a completely smooth inside.

- Joined

- Apr 27, 2004

- Messages

- 9,161

- Likes

- 5,762

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

Be careful the resists can pull you into sand-carving…..received my resist material in the mail yesterday so I'll be experimenting with that as well...

I had an article in the December 2016 AAW journal - it covers some basics on sand-carving.

Have fun. Interested in seeing what you come up with.

Except Bill Blasic. Who I've never seen demonstrate.Every pro turner demonstrating hollow forms that I've heard says they turn green wood. Maybe adding, "90% of the time".

Not a pro but I do what I do

There are plenty of people that turn dry wood in various forms. Segmented turnings use stable dry segments glued into rings and stacked together to create the size of hollow form desired. Dry solid billet wood blanks are also turned for various sized hollow forms desired, sharp tools and proper turning technique is required to make steady progress with turning dry woods compared to green/wet wood which is much easier and quicker to turn.

An amazing article... thanks for sharing Al.Be careful the resists can pull you into sand-carving…..

I had an article in the December 2016 AAW journal - it covers some basics on sand-carving.

Have fun. Interested in seeing what you come up with.

Trent Bosch did an IRD for our woodturning club a while back and it really got the wheels spinning in my head... apparently in the direction you've already gone (great minds think alike). I already had a lathe, sandblaster, and a Cricut... now that I've got a hollowing system (Bosch's of course) and resist material, I can finally try to get all of these ideas out of my head!

I turn both 1 and 2 turn HF's. Just depends on what the finished piece will be. The yellow vase was 2 turned, as the intent was a fully filled gloss finish, difficult to polish out if badly warped. If I want to texture with a rotating tool like the Sorby or smaller Elf tool, it needs to be 2 turned so its perfectly round., like the potpourri box or jar. How much of the ID will get returned depends on how much of it is accessible - the vase only down inside the neck, the jar all of it. Returning something like the vase will require a steady rest, as too much of the lower end is removed from the OD so there is not enough support for hollowing. End grain pieces won't deform as much as face grain and can be left a bit thinner for 2 turning. The 3rd pic is walnut burl that didn't warp too badly that I was able to just trim up and embellish some.

I do more 1 turn, down to 1/8" to 1/4" thickness. The 4th pic is end grain spalted white oak, 14-1/4" OD. The 5th pic is a 9" sphere, spindle turned to sphere shape, rotated to face grain orientation and the sphere finished, then hollowed.

All pieces dried with grocery bags or kraft paper sheets with tenons left on. They are remounted and sanded, finish applied, cured, buffed, before the tenon is removed as the last step. Depending on how warped a piece is, I may just rotate it by hand while using a drill sander. The same is true for buffing. I prefer to keep the piece lathe mounted so vs a mounted sander or buff wheel. I rotate the HS on my lathe to 90° to the bed and have full easy access to the turning.

I'd like to know where people get wood billets/blanks 8 or 10" cubed that are dry. The wax coated blanks I have purchased, which were several years old when I bought them, were still wet in the center when I cut them a few years later, enough to cause some warp.

I do more 1 turn, down to 1/8" to 1/4" thickness. The 4th pic is end grain spalted white oak, 14-1/4" OD. The 5th pic is a 9" sphere, spindle turned to sphere shape, rotated to face grain orientation and the sphere finished, then hollowed.

All pieces dried with grocery bags or kraft paper sheets with tenons left on. They are remounted and sanded, finish applied, cured, buffed, before the tenon is removed as the last step. Depending on how warped a piece is, I may just rotate it by hand while using a drill sander. The same is true for buffing. I prefer to keep the piece lathe mounted so vs a mounted sander or buff wheel. I rotate the HS on my lathe to 90° to the bed and have full easy access to the turning.

I'd like to know where people get wood billets/blanks 8 or 10" cubed that are dry. The wax coated blanks I have purchased, which were several years old when I bought them, were still wet in the center when I cut them a few years later, enough to cause some warp.

Attachments

Last edited:

Doug,I do more 1 turn, down to 1/8" to 1/4" thickness. The 4th pic is end grain spalted white oak, 14-1/4" OD. The 5th pic is a 9" sphere, spindle turned to sphere shape, rotated to face grain orientation and the sphere finished, then hollowed.

Your spalted white oak piece is outstanding. I've done a few large diameter, low profile end-grains - had mixed results. Congratulations on that piece.

I always twice turn with a boil and 8+months drying in between. But recently I've focused on mistletoe-burl mesquite - honey mesquite is the hardest, heaviest in N. America. But it's also the most stable. I turn it green and let it dry in a heated room with dehumidifier - no need to boil mesquite. Also, due to all the openings, if the log warps after first turning, only the openings change. Most guys that turn mesquite turn once and finish - any warp is undetectable.

John

Attachments

The first rule of drying wood is that the moisture has to migrate to the outside surface, therefore you need to reduce the thickness such as making boards or in the case of turned pieces rough turn to an even wall thickness. The best way to get an understanding of wood would be to read Hoadley's UNDERSTANDING WOOD.I'd like to know where people get wood billets/blanks 8 or 10" cubed that are dry. The wax coated blanks I have purchased, which were several years old when I bought them, were still wet in the center when I cut them a few years later, enough to cause some warp.

I understand that very well. That's why I asked where do people find large thick chunks of wood they claim are "dry". They may not throw water when turned but the interior is far from dry, ie the piece will warp as the wood reaches equilibrium.The first rule of drying wood is that the moisture has to migrate to the outside surface, therefore you need to reduce the thickness such as making boards or in the case of turned pieces rough turn to an even wall thickness. The best way to get an understanding of wood would be to read Hoadley's UNDERSTANDING WOOD.

lots of time woodturning clubs get offered large trees .....owners happy for club to have at it

Excuse me I understood that you wanted to know where to get them but the word "CLAIM" cleared that up.I understand that very well. That's why I asked where do people find large thick chunks of wood they claim are "dry". They may not throw water when turned but the interior is far from dry, ie the piece will warp as the wood reaches equilibrium.

There have been similar threads in the past where turners have stated that they have turned these so called dry blanks and then put them aside to finish drying. I myself never buy those blanks, but a few times I have been given large pieces of walnut that had been sitting for up to 40 years and when you get past the checking 4 to 6" from the surface the wood is still noticeably wet.