My friend Steve Sherman is developing this hollowing setup for close work for small pieces. He's calling it "The Nano Revolution," and I've got to say, the tools match the name. I'm the "turning thug," I usually stress tools to the max. This evaluation is no exception. I haven't spoken to Steve yet, and there is a good chance that you are reading this before him.

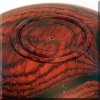

The cocobolo piece I just finished is probably as big as one could safely turn., maybe a little taller and narrower, but that will be pushing it.

My initial observation was that for my big fat hands, the knob on the end of the handle/grip was a little awkward, so he turned off the knob... Better for me.

The only other "negative" for me is that I keep running the offset hollower too hot which causes the super glued tip to come out. Here again, I'm AGGRESSIVE. I'm imagining that I would have the same kind of issues using the Elsworth tools with the glued in tips... This might be resolved (for me) with a little set screw to hold the tip in place.

Now, the GOOD stuff:

The tool steel stays sharp for a long time and the adjustable handles makes it pretty easy to have enough handle behind the tool rest to give excellent tool control.

So far, I have a straight and offset (Elsworth type) cutter/hollower set, a double ended Bedan/beading tool that works well. I like the beading end, I used it to form the bottom of this piece.

AND (I have to say) my favorite a round cutter/scraper that could smooth just about anything.

These are not all of the available tools, just the ones that I was given to test so far. As more roll out, I'm sure I'll get a chance to test them.

For small stuff, boxes, ornaments, small hollow forms and the like, these are easy to handle and work VERY well at the jobs they were designed for.

For me, there was practically no learning curve, the only "problem" that I had was making the bottom a bit too thin.

You will notice that the rim tapers in a bit, that gave me just a little more clearance so that I could hollow out further. I welcome questions as this is the first tool that anyone has given me to evaluate, and I'm sure that I am leaving out pertinent information.

The cocobolo piece I just finished is probably as big as one could safely turn., maybe a little taller and narrower, but that will be pushing it.

My initial observation was that for my big fat hands, the knob on the end of the handle/grip was a little awkward, so he turned off the knob... Better for me.

The only other "negative" for me is that I keep running the offset hollower too hot which causes the super glued tip to come out. Here again, I'm AGGRESSIVE. I'm imagining that I would have the same kind of issues using the Elsworth tools with the glued in tips... This might be resolved (for me) with a little set screw to hold the tip in place.

Now, the GOOD stuff:

The tool steel stays sharp for a long time and the adjustable handles makes it pretty easy to have enough handle behind the tool rest to give excellent tool control.

So far, I have a straight and offset (Elsworth type) cutter/hollower set, a double ended Bedan/beading tool that works well. I like the beading end, I used it to form the bottom of this piece.

AND (I have to say) my favorite a round cutter/scraper that could smooth just about anything.

These are not all of the available tools, just the ones that I was given to test so far. As more roll out, I'm sure I'll get a chance to test them.

For small stuff, boxes, ornaments, small hollow forms and the like, these are easy to handle and work VERY well at the jobs they were designed for.

For me, there was practically no learning curve, the only "problem" that I had was making the bottom a bit too thin.

You will notice that the rim tapers in a bit, that gave me just a little more clearance so that I could hollow out further. I welcome questions as this is the first tool that anyone has given me to evaluate, and I'm sure that I am leaving out pertinent information.