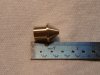

Got this little idea the other day and had a buddy turn it out of 3/4 in brass round stock. It allows me to chuck it in the headstock, put a brass tube on the lathe for ruffing up the surface and then use the same drive to hold one of the bushings for turning the actual segment of the pen. The little hole in the center of the point zeros up the error, if any . Filing the jaws true while turning slowly helps validate the surface for the flange to rest against.

-

December 2025 Turning Challenge: Single Tree! (click here for details) -

Congratulations to Bob Henrickson, People's Choice in the November 2025 Turning Challenge (click here for details) -

Congratulations to John Dillon for "Chinquapin Oak" being selected as Turning of the Week for December 22, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

New idea for pen turning

- Thread starter pfduffy

- Start date