Hello turners, my son and his wife wont's me to make them a mortar & pestle for their kitchen. I have been trying to figure out what would be a good food safe finish if any? I have carnauba wax on hand but don't know if it is absolutely food safe. Walnut oil is another. Any ideas? Thanks.

-

It's time to cast your vote in the January 2025 Turning Challenge. (click here for details) -

Conversations are now Direct Messages (click here for details) -

Congratulations to Alan Weinberg for "Elm Burl Bowl" being selected as Turning of the Week for January 27, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mortar & Pestle Finish

- Thread starter Lamar Wright

- Start date

Are they planning on actually using the mortar and pestle or will it be a show piece?

I would worry about any finish chipping/fragmenting and getting mixed in with whatever is being pulverized... also, I would think any film-type finish would potentially play havoc with the toothy quality you need for grinding in the mortar. Also, as is commented on in this Wikipedia article, you have the problem of absorption contamination and bacterial growth from food particles which get trapped in the wood:

https://en.wikipedia.org/wiki/Mortar_and_pestle

I would think, if you weren't wanting to leave it unfinished, you would probably want a neutral, food safe finish... I'd probably go with walnut oil.

I would worry about any finish chipping/fragmenting and getting mixed in with whatever is being pulverized... also, I would think any film-type finish would potentially play havoc with the toothy quality you need for grinding in the mortar. Also, as is commented on in this Wikipedia article, you have the problem of absorption contamination and bacterial growth from food particles which get trapped in the wood:

https://en.wikipedia.org/wiki/Mortar_and_pestle

I would think, if you weren't wanting to leave it unfinished, you would probably want a neutral, food safe finish... I'd probably go with walnut oil.

Oh, and for all of that, please keep in mind that I'm just theorizing. I've not yet made a mortar and pestle....

Geeze. I keep wanting to write it out as "Mortis and Pestle".

Geeze. I keep wanting to write it out as "Mortis and Pestle".

Walnut Oil, They can wash it and then reoil every month. Will last a lifetime

- Joined

- Apr 27, 2004

- Messages

- 9,095

- Likes

- 5,655

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

If it might reside in view much if the time you could finish the outside of the mortar and handle of the pestle with something like Waterlox which with built up coats you can buff to a nice looking finish showing off the wood.

A small bead or a vee can be used to separate the finishes. Need to be small not to trap food.

You can also get a crisp line by turning the inside and the end of the pestle after finishing.

Leave these areas an 1/8”proud finish and turn them away. You may have to turn and finish the base of the mortar and the top of the pestle handle depending on how you hold them on the lathe.

The business end of the pestle and the inside of the mortars I would leave unfinished or use walnut oil.

Hard maple and beech work well.

Pecan work well too but I haven’t used it for one.

They will enjoy it for a long time

Have fun and make them a rolling pin to go with it.

A small bead or a vee can be used to separate the finishes. Need to be small not to trap food.

You can also get a crisp line by turning the inside and the end of the pestle after finishing.

Leave these areas an 1/8”proud finish and turn them away. You may have to turn and finish the base of the mortar and the top of the pestle handle depending on how you hold them on the lathe.

The business end of the pestle and the inside of the mortars I would leave unfinished or use walnut oil.

Hard maple and beech work well.

Pecan work well too but I haven’t used it for one.

They will enjoy it for a long time

Have fun and make them a rolling pin to go with it.

Last edited:

Thanks Ronald, yes, they plan to use it for crushing herbs and would look nice on their kitchen counter. I'm thinking Walnut oil.Are they planning on actually using the mortar and pestle or will it be a show piece?

I would worry about any finish chipping/fragmenting and getting mixed in with whatever is being pulverized... also, I would think any film-type finish would potentially play havoc with the toothy quality you need for grinding in the mortar. Also, as is commented on in this Wikipedia article, you have the problem of absorption contamination and bacterial growth from food particles which get trapped in the wood:

https://en.wikipedia.org/wiki/Mortar_and_pestle

I would think, if you weren't wanting to leave it unfinished, you would probably want a neutral, food safe finish... I'd probably go with walnut oil.

Thanks Paul for that info. Walnut oil is probably what I'll use.Walnut Oil, They can wash it and then reoil every month. Will last a lifetime

Hi Al, thanks so much for those tips as they will be very useful and the roller pin is an excellent idea to go with the mortar and pestle. I have some seasoned big leaf maple that I plan on using. I checked the MC this morning and it is 9%. This will be my first mortar and pestle and think it will be a fun project + the roller pin. Thanks.If it might reside in view much if the time you could finish the outside of the mortar and handle of the pestle with something like Waterlox which with built up coats you can buff to a nice looking finish showing off the wood.

A small bead or a vee can be used to separate the finishes. Need to be small not to trap food.

You can also get a crisp line by turning the inside and the end of the pestle after finishing.

Leave these areas an 1/8”proud finish and turn them away. You may have to turn and finish the base of the mortar and the top of the pestle handle depending on how you hold them on the lathe.

The business end of the pestle and the inside of the mortars I would leave unfinished or use walnut oil.

Hard maple and beech work well.

Pecan work well too but I haven’t used it for one.

They will enjoy it for a long time

Have fun and make them a rolling pin to go with it.

I have not made one for use and as a Pharmacist I used mostly glass at work and a few stone (much better for grinding). I think Al made some very good points on finishing the outside . As to the inside and the pestle I would leave both unfinished to get better grinding characteristics. I think pecan or hichory would be good woods and take the pounding very well.

Hi Gerald, thanks for your ideas. As you and Al suggested, I don't think that I'll finish the inside of the mortar or the pestle since this item will be used and not just for looks. Just maybe some walnut oil outside of the mortar only. It needs to be dishwasher safe as well. By the way, I really like your work, very nice indeed.I have not made one for use and as a Pharmacist I used mostly glass at work and a few stone (much better for grinding). I think Al made some very good points on finishing the outside . As to the inside and the pestle I would leave both unfinished to get better grinding characteristics. I think pecan or hichory would be good woods and take the pounding very well.

My wood of choice would be Osage Orange. It is very hard and can be sanded to such a high gloss that it needs no finish. It is also so stable that it can be put in the dishwasher without distorting although that will give the exterior a satin finish. I have never used it to make a mortar and pestle but I do have a pair of corn boats that I made 35 years ago that are still in use and look better every year. The only problem is that the first few times you use it may shed some yellow color but that soon stops.

Hello Lamar:

Hello Lamar:AAW Explore! has several articles about food-safe finishes.

Steps

- Go to the AAW website at woodturner.org.

- Log in with your username and password. (If you don’t know your username and password, call the AAW office at 877-595-9094.)

- From the main menu, hover your mouse over “Read” and click “AAW Explore!”

- The AAW Explore search page will be displayed.

- In the section labeled “Category” select “Finishing” from the dropdown menu. In the section labeled "Keyword" select "Food-safe" from the dropdown menu. Then click the “Search” button.

- A list of all the articles will be displayed. Scroll down the list, if one of the articles is of interest, simply click the world icon in the “Links” column to open the article in a new window.

I hope this helps.

Kim

Last edited:

- Joined

- Apr 27, 2004

- Messages

- 9,095

- Likes

- 5,655

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

ve some seasoned big leaf maple that I plan on using.

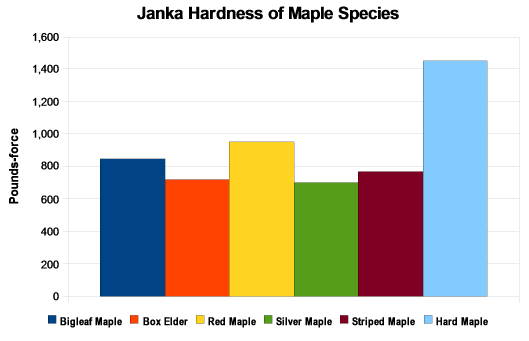

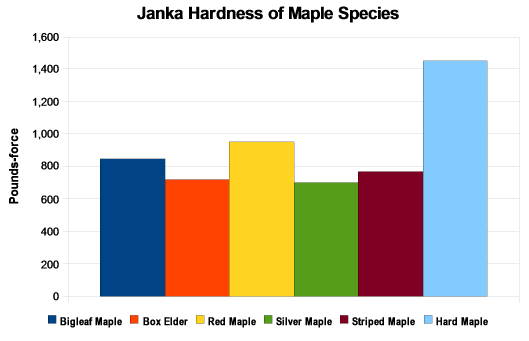

I have limited experience with big leaf maple. The pieces I have turned seemed soft about like our red and silver maples which would be too soft for me to use. The wood data base seems to agree with that.

Sugar maple and Black maple are the hard maples.

***** copied from the wood data base *****

http://www.wood-database.com/wood-articles/differences-between-hard-maple-and-soft-maple/

A common measurement of wood hardness is the Janka hardness test. The test measures the amount of force required to embed a .444″ diameter steel ball halfway into the wood. The results for each of the maple species are shown in the chart below.

No wood is dishwasher safe. If they put it in the dishwasher, it will destroy it. Walnut oil is for the inside and outside to seal the wood from moisture and food.

My wood of choice would be Osage Orange. It is very hard and can be sanded to such a high gloss that it needs no finish. It is also so stable that it can be put in the dishwasher without distorting although that will give the exterior a satin finish. I have never used it to make a mortar and pestle but I do have a pair of corn boats that I made 35 years ago that are still in use and look better every year. The only problem is that the first few times you use it may shed some yellow color but that soon stops.

Thanks Al for the wood database.com link. It can be very useful.I have limited experience with big leaf maple. The pieces I have turned seemed soft about like our red and silver maples which would be too soft for me to use. The wood data base seems to agree with that.

Sugar maple and Black maple are the hard maples.

***** copied from the wood data base *****

http://www.wood-database.com/wood-articles/differences-between-hard-maple-and-soft-maple/

A common measurement of wood hardness is the Janka hardness test. The test measures the amount of force required to embed a .444″ diameter steel ball halfway into the wood. The results for each of the maple species are shown in the chart below.

Thanks so much Kim, this is a huge help! Happy turning.View attachment 24950 Hello Lamar:

AAW Explore! has several articles about food-safe finishes.

Steps

- Go to the AAW website at woodturner.org.

- Log in with your username and password. (If you don’t know your username and password, call the AAW office at 877-595-9094.)

- From the main menu, hover your mouse over “Read” and click “AAW Explore!”

- The AAW Explore search page will be displayed.

- In the section labeled “Category” select “Finishing” from the dropdown menu. In the section labeled "Keyword" select "Food-safe" from the dropdown menu. Then click the “Search” button.

- A list of all the articles will be displayed. Scroll down the list, if one of the articles is of interest, simply click the world icon in the “Links” column to open the article in a new window.

I hope this helps.

Kim

Thanks for that info Paul, looks like Osage Orange may be a better choice of wood for this project because of its Stability as tdrice mentioned.No wood is dishwasher safe. If they put it in the dishwasher, it will destroy it. Walnut oil is for the inside and outside to seal the wood from moisture and food.

Thanks tdrice. Osage Orange just might be the better choice of wood for this project. Sounds like you have had good luck with this wood since you have made corn boats out of it. 35 years and no water problems, that says a lot! Thanks tdrice.My wood of choice would be Osage Orange. It is very hard and can be sanded to such a high gloss that it needs no finish. It is also so stable that it can be put in the dishwasher without distorting although that will give the exterior a satin finish. I have never used it to make a mortar and pestle but I do have a pair of corn boats that I made 35 years ago that are still in use and look better every year. The only problem is that the first few times you use it may shed some yellow color but that soon stops.

No wood is dishwasher safe. If they put it in the dishwasher, it will destroy it. Walnut oil is for the inside and outside to seal the wood from moisture and food.

I don't advocate putting any wood in the dishwasher but my Osage Orange corn boats were put in at least three times that I know of and a O O bowl twice of with no perceptible damage.

Wife ruined two cutting boards by putting them in the DW, even when I told her not to do it.

even when I told her not to do it, you would have had better luck demanding that she use the dish washer.

- Joined

- Jan 27, 2005

- Messages

- 13,046

- Likes

- 5,494

- Location

- Dalworthington Gardens, TX

- Website

- pbase.com

Wife ruined two cutting boards by putting them in the DW, even when I told her not to do it.

even when I told her not to do it, you would have had better luck demanding that she use the dish washer.

It doesn't matter, in either case it's your fault.

She uses the DW. Wouldn't be without one.

Question- If a married man is alone in the woods and says something, is he still wrong?

Question- If a married man is alone in the woods and says something, is he still wrong?

My wife says yes when I ask her that.She uses the DW. Wouldn't be without one.

Question- If a married man is alone in the woods and says something, is he still wrong?

- Joined

- Jan 27, 2005

- Messages

- 13,046

- Likes

- 5,494

- Location

- Dalworthington Gardens, TX

- Website

- pbase.com

She uses the DW. Wouldn't be without one.

Question- If a married man is alone in the woods and says something, is he still wrong?

Even if you think something without actually saying it .......

Does anyone recall the original thread?  Anyway, good info here, as on all threads I have read over the years.

Anyway, good info here, as on all threads I have read over the years.

Thanks for all the replies. I have learned a lot about safe food finishes from your posts. Especially not to put Mortar and Pestle in the DW.  I'll post a picture of the Mortar and Pestle on this thread when I finish this project. Thanks again.

I'll post a picture of the Mortar and Pestle on this thread when I finish this project. Thanks again.

would be a good food safe finish if any

none~!!! Any "finish" you put on it will end up as an ingredient in the first few things thy use it to make.

Odds are they'll either use it for muddling for mixed drinks or to crush garlic and herbs.

There is no finish that would be appropriate.

So, there is no food safe finish at all for wood utensils, bowls?none~!!! Any "finish" you put on it will end up as an ingredient in the first few things thy use it to make.

Odds are they'll either use it for muddling for mixed drinks or to crush garlic and herbs.

There is no finish that would be appropriate.

- Joined

- Jan 27, 2005

- Messages

- 13,046

- Likes

- 5,494

- Location

- Dalworthington Gardens, TX

- Website

- pbase.com

So, there is no food safe finish at all for wood utensils, bowls?

I believe that you misunderstood what Raul was saying. A mortar and pestle is used for crushing and grinding so it will grind the finish as well as whatever you are intending to grind. Just because something might be food safe doesn't mean that you ought to be intentionally eating it as if it were a seasoning such as salt, pepper, or paprika. My opinion is that a food safe finish means that it is safe to use on surfaces that come in contact with food, but not really suitable where the finish will be subjected to cutting or grinding. So, I wouldn't use a film finish on a cutting board, for example.

I wouldn't categorically say that all finishes are safe once the finish has cured. Things can leach out of art paints which may contain harmful ingredients such as lead chromate, cadmium, manganese, and many other things. However, I believe that most oil finishes, varnishes, shellac, and lacquer are food safe. Just think about how something will be used and whether a film finish will hold up.

Thanks Raul for your info, the main use for the Mortar and Pestle will be for crushing herbs.none~!!! Any "finish" you put on it will end up as an ingredient in the first few things thy use it to make.

Odds are they'll either use it for muddling for mixed drinks or to crush garlic and herbs.

There is no finish that would be appropriate.

Thanks Bill for this info. I am making the Mortar and Pestle out of dried Maple and not use any finish at all.I believe that you misunderstood what Raul was saying. A mortar and pestle is used for crushing and grinding so it will grind the finish as well as whatever you are intending to grind. Just because something might be food safe doesn't mean that you ought to be intentionally eating it as if it were a seasoning such as salt, pepper, or paprika. My opinion is that a food safe finish means that it is safe to use on surfaces that come in contact with food, but not really suitable where the finish will be subjected to cutting or grinding. So, I wouldn't use a film finish on a cutting board, for example.

I wouldn't categorically say that all finishes are safe once the finish has cured. Things can leach out of art paints which may contain harmful ingredients such as lead chromate, cadmium, manganese, and many other things. However, I believe that most oil finishes, varnishes, shellac, and lacquer are food safe. Just think about how something will be used and whether a film finish will hold up.

Lamar - yesterday I received the April issue of the British magazine "Woodturning" and lo and behold but it had a short 1 page article on a "Pestle and Mortar" design. According to the article, they suggest a light colored hardwood like maple or beech and suggest "No finish needs to be applied although a food-safe finish can be used."

If you're interested in the article, I have seen the magazine for sale at my "local" Barnes and Noble (an hour away)... Should be in the Crafts section of their magazines.

If you're interested in the article, I have seen the magazine for sale at my "local" Barnes and Noble (an hour away)... Should be in the Crafts section of their magazines.

Hi Ronald, thanks so much for that information. I'll go to our local Barnes and Noble and pick up the latest copy. I usually pick up a copy of Woodturning magazine when I'm there. Thanks again and happy turning.

So, there is no food safe finish at all for wood utensils, bowls?

No not at all. In fact pretty much every finish is essentially food safe once it's cured. The thing is only a few manufacturers are going to undertake the enormous cost of going through the FDAs requirements for a certification. So hobby woodworkers are on their own. But No one will get sick from that bowl you made with urethane or shellac, or a water based or even a real lacquer or rattle can finish. There's no lead in anything any more and that was really the only toxin. Some colors might be an issue but most of them are all compliant too.

Shellac is used on many food products as a protective coating, vitamins, pills, candy, jerky, etc. Many wood turners make their own Shellac finishes which can be made of safe simple components that will leave only the Shellac behind after the other compounds evaporate.