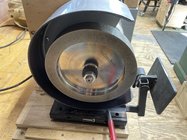

For what it’s worth, I took a swing at this in my new shop space. I scored a refurb deal on a JET JDCS-505, a metal dust collector stand for bench grinders. The grinder is a Baldor 8” with cast iron guards and rear extraction ports. Jury’s still out as to whether this is a viable approach, and under what circumstances. I’m hoping that it’ll be good to maintain air quality for sharpening while turning. I’ll be surprised if it’s adequate for heavy grinding operations, e.g. major tool reshaping, grinding a custom tool from an HSS blank, etc. The collector definitely helps significantly with metal dust, but I’ve only just gotten measurement capability setup today (via a Dylos D1100) and have been preoccupied getting used to it and sorting out baselines. In the meantime, it’s the trusty P100 half mask until I know I’m getting adequate collection.

I haven’t employed any magnets yet, as I want to understand how well the dust collector works on its own. As I dial things in, it may be possible to use magnets to augment the collector’s effectiveness, ala magnetic dust guides.

(and this from just a few hours ago: yes, you can squeeze a 1.5” wide CBN wheel into the 8” Baldor‘s guards with some arbor spacers.)