I’m in the middle of some lathe maintenance and I figured it’s about time I get the lathe totally level so my tools can stop rolling off of the ways. My question is, does anyone produce leveling feet for the oneway? Mine just has exposed bolts in the bottom. The previous owner may have had something but he is unavailable. I already searched the the Oneway website under 2000 series accessories. I wouldn’t mind getting something aftermarket. Thanks all!

-

April 2025 Turning Challenge: Turn an Egg! (click here for details) -

Congratulations to Kelly Shaw winner of the March 2025 Turning Challenge (click here for details) -

Congratulations to Ellen Starr for "Lotus Temple" being selected as Turning of the Week for 21 April, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Leveling guide for Oneway 2436

- Thread starter Aidan Lasky

- Start date

I leveled mine perfectly on a really crooked floor a few years ago. My 2436 was made in 2000 and has a rectangular bar under each foot. There are screws from the body that can be adjusted to those bars. All you need is a level. I would call oneway and speak to Kevin about what's missing for your particular version.

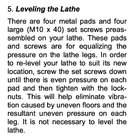

Interesting. I have no feet on mine. Thank youThis is under instructions for levelling, and evenly setting the pressure on the feet, HTH

View attachment 44435

View attachment 44436

You can probably find them at specialty fastener stores, or from Oneway. The process, which I don't think I have ever seen written up, is to first make the lathe as level as possible, side to side and front to back. Then loosen one foot only. Put an unbalanced piece of wood on the lathe and spin at fairly low speed. The lathe will rock. screw the one 'loose' foot down till vibration pretty much stops. I then do about 1/8 of a turn more. When you tighten up the 'set' nut on top, that seems to draw the bolt back up a bit. You may have to do it a couple of times to get it right.

robo hippy

robo hippy

It is not a foot Reed, it is a plate where the setscrew pushes down against, if the setscrews are there in the OP's lathe, all he needs is 4 steel plates under the lathe and use the set screws to level and equalize the pressure on the 4 corners.You can probably find them at specialty fastener stores, or from Oneway. The process, which I don't think I have ever seen written up, is to first make the lathe as level as possible, side to side and front to back. Then loosen one foot only. Put an unbalanced piece of wood on the lathe and spin at fairly low speed. The lathe will rock. screw the one 'loose' foot down till vibration pretty much stops. I then do about 1/8 of a turn more. When you tighten up the 'set' nut on top, that seems to draw the bolt back up a bit. You may have to do it a couple of times to get it right.

robo hippy

If he does not have the setscrews he will need 4 M10 setscrews as well.

I have the screws just not the plates. Couldn’t find them in the Oneway website.It is not a foot Reed, it is a plate where the setscrew pushes down against, if the setscrews are there in the OP's lathe, all he needs is 4 steel plates under the lathe and use the set screws to level and equalize the pressure on the 4 corners.

If he does not have the setscrews he will need 4 M10 setscrews as well.

Thank you for the instructions!You can probably find them at specialty fastener stores, or from Oneway. The process, which I don't think I have ever seen written up, is to first make the lathe as level as possible, side to side and front to back. Then loosen one foot only. Put an unbalanced piece of wood on the lathe and spin at fairly low speed. The lathe will rock. screw the one 'loose' foot down till vibration pretty much stops. I then do about 1/8 of a turn more. When you tighten up the 'set' nut on top, that seems to draw the bolt back up a bit. You may have to do it a couple of times to get it right.

robo hippy

- Joined

- Apr 27, 2004

- Messages

- 9,160

- Likes

- 5,761

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

These plates come with the lathe and don’t wear out so there isn’t a big demand.I have the screws just not the plates. Couldn’t find them in the Oneway website.

Call ONEWAY they like to keep track of the owners….

Kevin will help you.

If you want to make your own. They are pieces of flat steel with a 1/2 or 5/8 twist drill hole about a 1/8” deep in the center.

The little divot centers the leveling bolt. A used mower blade with flat sections will work

Last edited:

To echo Hockenbery, I'd be calling Kevin at Oneway. Why spend more on a less than optimum solution?

The plates are just a piece of steel with a drill point drilled in them to center the bolt and keep them in place.

Out of curiosity, I goggled leveling feet by requesting"M10x40 leveling feet" and came up with hundreds of bolts with feet built on them like those on my 3520B. Some rated to 4500 lbs...Would also need the thread pitch, I'm guessing the 40 is the length. some have rubber pads, some do not, some stainless, all kinds. The way Reed explained his method above is exactly how I took all the vibration out of mine.

Here's an idea, 20 bucks for 4, rated at about 2200 lb. : https://www.amazon.com/Wolfride-Mac...ocphy=9025861&hvtargid=pla-967420978790&psc=1

Here's an idea, 20 bucks for 4, rated at about 2200 lb. : https://www.amazon.com/Wolfride-Mac...ocphy=9025861&hvtargid=pla-967420978790&psc=1

Last edited: