pics of ways to move a heavy lathe

-

December 2025 Turning Challenge: Single Tree! (click here for details) -

Congratulations to Bob Henrickson, People's Choice in the November 2025 Turning Challenge (click here for details) -

Congratulations to Guillaume Fontaine for "Old Tea Pot" being selected as Turning of the Week for December 15, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lathe mobility

- Thread starter Larry Mercier

- Start date

I was not specific enough. I want to know how to move a heavy lathe within my shop. I looked for castors in powermatic accessories but came up empty.

No pics but the couple times I moved mine I just use a rolling car jack to lift one end at a time and put a little 3 wheeled furniture leg castor under each foot. Move it to where I want and then jack up and remove. Since I don’t move it much it works just fine. If I moved it everyday I might get a hydraulic table lift to do it all at once.

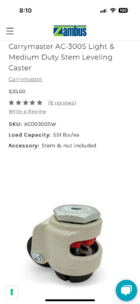

I don’t have specific experience with Powermatic lathes, but for my shop’s jointer I used Zambus CarryMaster casters. These let me easily roll the jointer around as needed, then once settled, I lower the feet via the red dial (see below) to fix it in place during use.

Another alternative, which is what I use for my lathe (a Nova Galaxi) is to scoot a hydraulic lift cart under it, lift the entire lathe and roll it away, then drop the lathe off as needed. There’s a whole ecosystem of (relatively) inexpensive models, e.g. from Harbor Freight and the like, and lots of fancier models. A good item for scouting on your local Craigslist, etc.

I also have Zambus castors on my PM3520 (see pic in your storage thread). Very happy with them. Seldom screw down the rubber stops, move my lathe around a couple feet often. Very stable when turning without putting stops down.

Thanks for the suggestion and pics. It wasn't I that asked, but it looks like a solution worth investigating.I don’t have specific experience with Powermatic lathes, but for my shop’s jointer I used Zambus CarryMaster casters. These let me easily roll the jointer around as needed, then once settled, I lower the feet via the red dial (see below) to fix it in place during use.

View attachment 49172View attachment 49171

I have a Nova DVR-XP for which I made a stand/cabinet with shop made casters. It's a simple system with a single piece of 1/1/4 conduit running the length, wood mounted casters and a block of Jatoba cut to act as a cam. I raise it about an inch using a piece of 3/4 inch of conduit (on left) dropping the caster into play. Has worked well. My Nova is 180lb's, plus another 40 for the outrigger and bed extension. In the cabinet are 4 50lbs of sand on the bottem and about 100lbs of tools/accessiories and another 120lbs of weights hiding behind the motor. Total weight I estimate about 650-800 lbs.

I don't have a good pic just of my caster system, but attached is what I've got . if you'd like more detail just let me know.

I don't have a good pic just of my caster system, but attached is what I've got . if you'd like more detail just let me know.

I used a hydraulic lift cart for a while and it worked great.

Now there's someone who has a better use for the outrigger than I do.I have a Nova DVR-XP for which I made a stand/cabinet with shop made casters. It's a simple system with a single piece of 1/1/4 conduit running the length, wood mounted casters and a block of Jatoba cut to act as a cam. I raise it about an inch using a piece of 3/4 inch of conduit (on left) dropping the caster into play. Has worked well. My Nova is 180lb's, plus another 40 for the outrigger and bed extension. In the cabinet are 4 50lbs of sand on the bottem and about 100lbs of tools/accessiories and another 120lbs of weights hiding behind the motor. Total weight I estimate about 650-800 lbs.

I don't have a good pic just of my caster system, but attached is what I've got . if you'd like more detail just let me know. View attachment 49176

yep! With the headstock pivoted 90 degrees the outrigger allows me to roughout out bowls that are a little to big to spin over the lathe bed. However once turned round I move it back to the normal position. I do use the pivoting head a lot, (particularly when hollowing) though at the 23 degree position but there I can still reach it from the banjo.Now there's someone who has a better use for the outrigger than I do.

What size zambus castor did you get?I also have Zambus castors on my PM3520 (see pic in your storage thread). Very happy with them. Seldom screw down the rubber stops, move my lathe around a couple feet often. Very stable when turning without putting stops down.

Even with 880 lbs of sand on the shelf, I could just pick it up and roll it around. I have a pair of dollies with a hydraulic jack that pushes the wheels down to pick stuff up. The wheels also steer by moving the handle to one side or the other. They're very handy for moving heavy machinery, safes/vaults, pianos, etc.

Attachments

I have a powermatic 3520c and bought the zambus ac30-s castors. As I stated in another post I'm not satisfied with them for use on a wood lathe. The lathe shakes when you have an unbalanced piece of wood on it when roughing out a bowl. When I set it up I used a precision level to level the lathe and made sure all feet had equal pressure on them. The problem with these castors is the rubber foot that supports the lathe is too thick and not hard enough of material and lets the lathe move side to side. I checked it with the lathe running. I talked to Zambus before I bought them and this is what they recommended for this application. I think they would be fine for something like a jointer, band saw, etc. Also the stud for the castor is 12mm x 1.75 thread. A powermatic foot stud is 1/2" x 12 tpi so it isn't quite a perfect fit for threads. When I get my lathe moved to it's permenant location the castors are coming off and the factory feet are going back on. I had no shake or wobble with the factory feet.What size zambus castor did you get?

AC - 300; I’ve been using these happily for 15-20yrs, they also allowed me to stack the lathe up a little higher with the oak blocks (I’m 6’3”)What size zambus castor did you get?

Attachments

I have a PM 3520C. I use a 1000lb capacity hydraulic lift table to move it around. It's very easy. I put 2 - 2x4's 24" long placed perpendicular to the lathe bed on the hydraulic table and move the table under the lathe bed. I raise the table/lathe by pumping a foot pedal. I purchased mine from Harbor Freight and have had it over 5 years without any issues. There are also other sellers of similar tables. The table comes in handy for other uses in the shop as well.

Motorcycle lift from Harbor Freight. Cheaper than a lift table and it works. Casters are awful, but it moves.

- Joined

- Apr 27, 2004

- Messages

- 9,307

- Likes

- 6,071

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

That’s a good alternative, especially if you have a motorcycle or other uses for it.Motorcycle lift from Harbor Freight. Cheaper than a lift table and it works. Casters are awful, but it moves.

I use my hydraulic table the most as an auxiliary table for the bandsaw.

Big blank slides from the hand truck otto the HT.

Raise the table level with the bandsaw table then cut the round with full support.

It can then roll to the lathe for a short lift.

I also have a table top sandblast cabinet that works great on top of the HT.

Great for working with concrete bench’s too

I know you mentioned casters but my wife and I just recently moved a large lathe from storage in Northern Virginia to my shop in Florida by ourselves using this shop lift from Harbor Freight. https://www.harborfreight.com/1-ton-capacity-foldable-shop-crane-58794.html I was impressed with the quality of the product, the directions (each part was individually labeled), the ease of construction and the ease of use. My wife was able to jack up the lathe very easily with one hand and roll the lift down the incredible narrow hallway of the storage facility. The lift also folds up so storing it isn't bad. I'll be using it in my shop to more tools and wood around.

For less heavy equipment I like these PowerTec casters. They're removable so you can store them out of the way once you get your equipment placed. They also fold up and down which makes them easier to use.