- Joined

- Oct 7, 2009

- Messages

- 128

- Likes

- 16

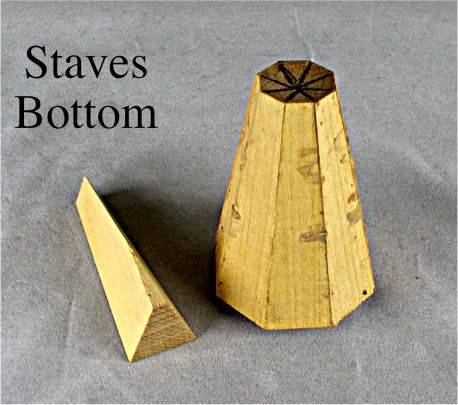

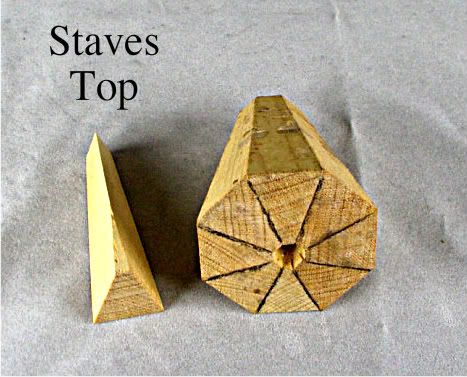

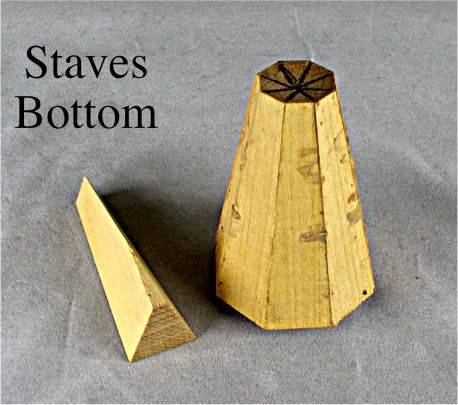

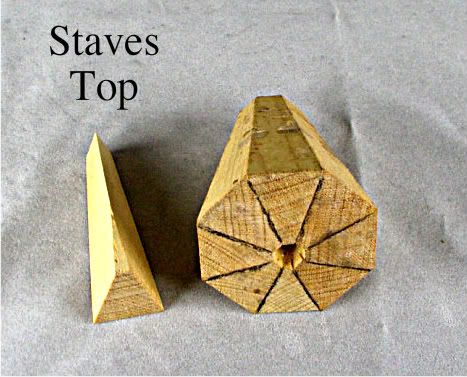

Does anyone have any photos of their jig for cutting compound staves.??? I have included some photos of what I am attempting to do. I cut these on my tablesaw with a crude setup and alot of guess work. I was not happy with the results because of safety and could not make them small enough. These are about 3" in length. Would like to make them about 2" and thinner. Thanks in advance. Also is there some formula for calculating the angles and all.??? The tapering is not easy either. Appreciate any help. Thanks.