The nib in the inside is different from the outside. For the outside, try this technique Mr Ellsworth teaches. I show it on this page of one of my How To articles.

http://www.turningwood.com/square4.htm

Basically a very small shallow gouge ground in a teardrop sort of, and supported with a live center with a small point on it.

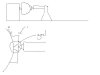

I use the same method as Steve. I had a bit of trouble seeing what he was referring to in his link though so I took a minute to scratch out a picture.

To remove the bottom nib on the outside. I usually hold the piece with the opening of the bowl or hollow form facing the headstock, using a jam chuck, with the live center up against the bottom of the bowl. Pressure from the tail is just enough for the piece to turn without spinning loose.

As Steve said, I use a small detail gouge that had been ground to a teardrop or even a spear like point. I start with the flute facing the headstock and make cut 1. Then I reverse the flute and make cut 2. I repeat that until I am left with a little cone at the bottom of the bowl, shown in the circle labeled goal. The tip of the cone is pretty small and delicate at this point.

Then, I position my gouge for cut 2 with the cutting tip not quite touching the tip of the cone. I am only holding it with my right hand. The lathe is probably running at only 200 to 300. Pretty slow. With my left hand I shut off the lathe. As it spins down I quickly move my left hand under the bowl, and then push lightly with the gouge to cut off the cone. The bowl will drop into your left hand. It will not fly away. The tip of the cone at that point was obviously pretty delicate for a light push to sever it.

Before I do this I usually lay a cloth or thin sheet of foam rubber on the bed of the lathe under the bowl. Just in case I don't catch it. Hasn't happened yet, but Murphy and I are good friends and I know it will happen.

This really produces a clean bottom surface. The process seems really scary, but the first time you do it you will say....woooohooo! That was easy.

The earlier description of eliminating the inside nub is how I usually tackle that. That also works great most of the time. It works whether I am using a scraper as described, or my Kelton hollowers (small scrapers if you think about it) or my bowl gouge. Very clean. Little sanding needed. Unlike the bottom nib removal we described this seems so simple but takes a little to get used to. You might try it on a bowl well before you are actually ready to finish the bottom. Let a nib form, remove it. Continue hollowing the bowl. Let a nib form, remove it, etc. By the time you are ready to finish it off you will be comfortable with the process.

Be sure to holler at us if we (me? <grin>) made no sense to you and we can try explaining it again.

Dave