- Joined

- Dec 26, 2008

- Messages

- 9

- Likes

- 0

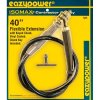

Penn State Industries sells a flexible shaft sander kit for round pad sanders. Short of a Fordom type tool, I've not seen flexible shaft sanders advertised elsewhere. Does any one have any experience with this tool? The shaft is driven by a portable drill. It seems to me that the advantage is that it is much easier to use than holding a drill motor with a pad on it. On the other hand, does the flexible shaft adequately deliver the power. I'm just curious about others' experience. Thanks.

By the way, I am new to turning and this site has been a very valuable resource for me.

Greg Millert

By the way, I am new to turning and this site has been a very valuable resource for me.

Greg Millert