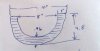

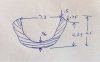

I am in the process of drying my first few bowls in paper and have a few questions.

1. I bought kraft paper on a roll from Home Depot. Any issue with that. It's about the weight of a paper grocery bag

2. I have them sitting in my basement shop. Temperature in the shop approx 66 degrees. I could also put them in a solid concrete room (floor, walls and ceiling). Would that be better because its a bit cooler and a little higher humidity?

3. I don't have a fan blowing? Is air movement more that the normal air in a house okay or having a fan better?

4. Kind of surprised but bowls started out at 35% and after 10 days only down to 25%. Not sure why I'm surprised since Ive never done this before but thought they would dry quicker. I have them down to approx 3/8 thick with the plan of finished thickness of 1/4 inch after final shape and sand.

Any help would be appreciated

1. I bought kraft paper on a roll from Home Depot. Any issue with that. It's about the weight of a paper grocery bag

2. I have them sitting in my basement shop. Temperature in the shop approx 66 degrees. I could also put them in a solid concrete room (floor, walls and ceiling). Would that be better because its a bit cooler and a little higher humidity?

3. I don't have a fan blowing? Is air movement more that the normal air in a house okay or having a fan better?

4. Kind of surprised but bowls started out at 35% and after 10 days only down to 25%. Not sure why I'm surprised since Ive never done this before but thought they would dry quicker. I have them down to approx 3/8 thick with the plan of finished thickness of 1/4 inch after final shape and sand.

Any help would be appreciated