Get a REAL MINI-LATHE - ... NOT the Dremel...

Michael:

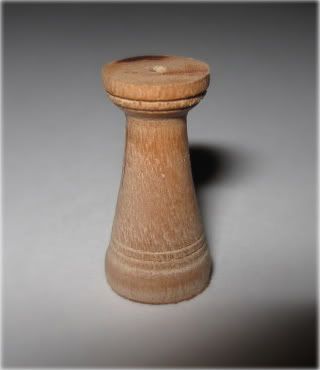

You are asking some correct questions at this stage, particularly whether the Dremel Moto lathe is worth it.... in my opinion, it is NOT - it's far too small to do anything really useful with, and the 'floundering time' you will likely spend with it will dissuade and discourage you on how wonderful woodturning really is. This lathe won't let you turn cross-grain bowls and vessels or spindles of any useful size, and thus you will be extremely limited in what you can make and do in woodturning. I think you would be throwing good money away with limited productive outcome for your time and monetary efforts.

My first suggestion is to look at a TRUE mini-lathe, such as the Jet mini (JWL1014) as a first lathe. Several newer lathes, including the new Delta 12" 46-460 are worthy of consideration, but may be more money than you want to spend. Hundreds, if not thousands of turners have used the Jet Mini lathe, or ones similar to it, as an entry-level machine. Other small- to mid-sized lathes are out there (many on the used market too), which would be a much better choice than the Dremel Moto-lathe. You will be severely constrained at the start, and I don't think that you'll get very much productive woodturning experience from this small "machine". I would not go there.

My second suggestion is to find a local woodturning club, get in touch with one or more of its members, and REALLY learn about turning in real time from some live people (...well, most are usually alive!). Attend one or more of their meetings, explain that you are a very interested newcomer to woodturning, buckle your seat belt low and tight across your lap, and then get ready for one of the best rides you'll have in woodworking (..or art, if you aspire to head in that direction). Almost every woodturner I've ever met will be more than happy to let you try your hand at woodturning and will provide advice on various lathes, which turning tools are needed, local sources of wood, sharpening, etc. that will fit your unique situation, interests and skill levels. (This kind of information is hard to answer and provide advice on over the Internet without a LOT more information from you). It might be useful to build your public profile on the AAW site to (minimally) include where you are from. I would have made some suggestions on clubs to contact in your area, but I can't tell if you're in Denver, Chicago, Tokyo, or lower Slobbovia....

You have come to the right place for answers and suggestions about your woodturning question(s) [...and others may differ with my recommendation to not waste money on a Dremel Moto lathe], but nothing beats face-to-face learning and getting advice that can be gained from directly interacting with local turners, or through a local turning club.

Look at real mini-lathes to get started, talk with local turners, and get some hands-on instruction and advice, and you'll be well-off to enjoying the increasing vortex of fun that is woodturning. Above all,

Turn safely,

Rob Wallace