I'm going to take down a tree during the holidays, and I'd like to save my back this time by putting the chunks up on some sort of elevated platform for slabbing instead of trying to do this at ground level. Does anyone have a picture or plans for a stand I can copy from? I recall David Ellsworth showing such a thing in an AAW video from a couple years ago; he promised to send out plans but I've never seen them. He had a sort of V-shaped trough on four legs.

-

December 2025 Turning Challenge: Single Tree! (click here for details) -

Congratulations to Bob Henrickson, People's Choice in the November 2025 Turning Challenge (click here for details) -

Congratulations to Guillaume Fontaine for "Old Tea Pot" being selected as Turning of the Week for December 15, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

chainsaw stand

- Thread starter Karl Best

- Start date

- Joined

- Feb 28, 2021

- Messages

- 1,770

- Likes

- 1,584

- Location

- Roulette, PA

- Website

- www.reallyruralwoodworks.com

Look up Sam Angelo on Youtube, is the first one (with a name I can remember) that comes to mind, there are also a couple featured in American Woodturner past issues - in fact think there was a relatively recent (last 6 months or so) discussion on here about just such a stand.

- Joined

- Apr 27, 2004

- Messages

- 9,304

- Likes

- 6,059

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

That's pretty much what I've been doing for the past few years. But I've got to get the chunks up higher off the ground. I just can't be bending over with the chainsaw any more.This is simple and is about the best you’ll find

Log section rolls on from hand truck no lifting.

Kneeling on one knee I cut with my back straight.

Works for half logs and crotches

You can make one in the field

Dave Landers

Beta Tester

This one was in American Woodturner, June 2020 - tiny.cc/sawbuck

Here is a post of mine that I copied and modified from Davin Elsworth's.

www.aawforum.org

www.aawforum.org

David Ellsworth demo today

Regrettably, I missed the deadline to register for David's demo on Natural Edge bowl turning this afternoon. Is it too late for me to join? I would be happy to be able to view the video when it is posted later. Thank you in advance. Sean

- Joined

- Jul 18, 2018

- Messages

- 1,329

- Likes

- 2,863

- Location

- Baltimore, MD

- Website

- loujacobswoodturning.com

Here’s mine, if you can make it out under the sawdust and the 13” beech log. It’s got a V shaped top and a gap between the two sides. Every once in a while I need to replace the top planks that eventually get chewed up. They are held in place with pegs so there is no metal hardware anywhere I might cut.

Several years ago a club in Minnesota published their plans for a chainsaw stand that works great. I've seen several variations with add-ons that help, but here's the basic:

https://www.mnwoodturners.com/cms-files/log-cutting-stand-dimensions.pdf

https://www.mnwoodturners.com/cms-files/log-cutting-stand-dimensions.pdf

- Joined

- Apr 27, 2004

- Messages

- 9,304

- Likes

- 6,059

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

I don’t bend over either.That's pretty much what I've been doing for the past few years. But I've got to get the chunks up higher off the ground. I just can't be bending over with the chainsaw any more.

I kneel on my right knee back straight

I might start the cut standing with the bar at 45 degrees back straight.

You could always put the stump on a platform or dig a pit beside it.

My back is lot happier with the heavy stuff close to the ground.

- Joined

- Feb 28, 2021

- Messages

- 1,770

- Likes

- 1,584

- Location

- Roulette, PA

- Website

- www.reallyruralwoodworks.com

I do like Hockenberry - knee on the ground, back straight (Though I do wear rollerblader's knee pads over my chaps) I feel much more stable and "in place" that way, than I would standing on my feet .. and no "toes in the way under the cut" - Much easier to roll a log onto close-to-the-ground cutting block than back strain trying to lift it up onto a sawbuck.

I made this one from a Fine Woodworking tip. It works ok for logs up to 16” diameter or so. Found another one awhile back on YouTube I liked better. I have not made it yet. I’ll post a link to it if I can find it again.

https://www.finewoodworking.com/201...to-convert-fresh-cut-logs-into-turning-blanks

https://www.finewoodworking.com/201...to-convert-fresh-cut-logs-into-turning-blanks

Just saw Larry’s post after I posted the FW link. The sawbuck style bench that Larry posted is the other design I was referring to. I think it’s a nicer design and can handle larger logs. With the bench from the FW tip, you need to screw into the end of the log to prevent it from rotating.

- Joined

- Jul 18, 2018

- Messages

- 1,329

- Likes

- 2,863

- Location

- Baltimore, MD

- Website

- loujacobswoodturning.com

George, Daytona Beach? Snow on the ground?I made this one from a Fine Woodworking tip. It works ok for logs up to 16” diameter or so. Found another one awhile back on YouTube I liked better. I have not made it yet.

Look up saw bucks on U-Tube.

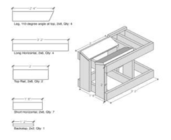

I don't have plans, but here are some images of what I built based on David Ellsworth's version. All of the pieces exposed to the chainsaw are screwed from the bottom so a) it is harder to hit metal with the blade and b) so I can swap them out when they get beat up.

It is about 2' wide and 4' long. If I had to do it over again, I would probably shorten the "V" portion to make the overall length about 3' instead. Also, the cross pieces at the bottom of the legs were moved up onto the ends so it stands on four feet instead of the two bottom 2x4s. Otherwise, the real thing is like the model. It's probably overbuilt like everything I do, but it works well.

I hope this helps some.

Steve Pritchard

It is about 2' wide and 4' long. If I had to do it over again, I would probably shorten the "V" portion to make the overall length about 3' instead. Also, the cross pieces at the bottom of the legs were moved up onto the ends so it stands on four feet instead of the two bottom 2x4s. Otherwise, the real thing is like the model. It's probably overbuilt like everything I do, but it works well.

I hope this helps some.

Steve Pritchard

Here is the one I've made. I will tilt it over on its side to trim edges off of the blanks to make them round. I have gone as far as to drill several one inch holes in increments from the edge so I can center drill the blanks and place a dowel in the appropriate hole. That allows me to make a cut then unclamp the blank and rotate it and make successive cuts. Thats for blanks that won't fit on my 14" bandsaw. On its side I use large quick release clamps to hold the blank in place while trimming it.

A lot of great looking stands. But for me personally, I bought a nice pair of good quality knee pads and just kneel down on the ground to cut my logs. Lifting the logs onto the stand is as bad or worse on my old back than bending over to cut them. I have a deep "nest" of wood shavings that I rest the log in and the shavings also save the chain from ground contact.

- Joined

- Aug 31, 2006

- Messages

- 346

- Likes

- 140

- Location

- Montgomery, TX

- Website

- www.gulfcoastwoodturners.org

I have been using a B&D workmate with a couple of 2x4"s to increase the v action. I really like the log section with a v. I have one I use for splitting. the next time I process logs I will cut a v in it and try it out.

Pat

Pat

I built Carl Ford's version:

Carl's Chainsaw Bench ⋆ Carl Ford Studio Woodturner

Carl's chainsaw bench is built like a tank. For woodturners. It was designed to make things safer. Photos & plan PDF.

carlford.us

I built Carl Ford's version:

Carl's Chainsaw Bench ⋆ Carl Ford Studio Woodturner

Carl's chainsaw bench is built like a tank. For woodturners. It was designed to make things safer. Photos & plan PDF.carlford.us

I build a sawbuck 10 years ago, where I used pressure treated woodI had here, legs are 6X6 and end piece is 2X12, the top rails are pinned with 5 inch oak pegs I turned and hammered in, I use it to cut my firewood (about 10 cubic meters every year) mostly dead and uprooted logs of all sizes I have here.

It is a heavy monster, but I only have to move it from the storage and back only once a year, I thought I had some pictures , but can't find them, I do know I posted them on SMC at some time years ago.

Found these pictures on the net of one that is very similar to mine, the main difference is that my pins are much farther to the outside as the beams are on the outside of the legs, I like that better because I can slide the logs and rotate them better that way.

This is the only picture I can find of the one I build and use, there is no metal in the top, so it is safe for my chainsaw.

It is a heavy monster, but I only have to move it from the storage and back only once a year, I thought I had some pictures , but can't find them, I do know I posted them on SMC at some time years ago.

Found these pictures on the net of one that is very similar to mine, the main difference is that my pins are much farther to the outside as the beams are on the outside of the legs, I like that better because I can slide the logs and rotate them better that way.

This is the only picture I can find of the one I build and use, there is no metal in the top, so it is safe for my chainsaw.

If the log style of saw rest that Al shows, and which you have used, is not high enough for your back, cut a longer log.That's pretty much what I've been doing for the past few years. But I've got to get the chunks up higher off the ground. I just can't be bending over with the chainsaw any more.

We are 'blessed' with many large cottonwood trees in our area, which are pretty worthless for turning, but make great saw rests. You probably have something similar in your area, such as willow. After 5-6 years, they rot and I have to go cut another one, but they're free and effective, and best of all, they really stay in place. The only hard part is rolling it up into the pickup. Maybe one of the Log Lifters featured in a recent thread, and well illustrated by Mike Peace's video, will be in my future.

- Joined

- Aug 31, 2006

- Messages

- 346

- Likes

- 140

- Location

- Montgomery, TX

- Website

- www.gulfcoastwoodturners.org

This is a YouTube video by Sam Angelo. He got the design from June 2020 American Woodturner. Created by Bill Gray in our woodturning club. Note: A small change to the design allows the saw buck to fold flat. Make the fold up so that when folded side folds up and the other side folds down.

View: https://www.youtube.com/watch?v=1qJPSA2BAOk

Check out the article I wrote for Fundamentals Feb 2022 issueI'm going to take down a tree during the holidays, and I'd like to save my back this time by putting the chunks up on some sort of elevated platform for slabbing instead of trying to do this at ground level. Does anyone have a picture or plans for a stand I can copy from? I recall David Ellsworth showing such a thing in an AAW video from a couple years ago; he promised to send out plans but I've never seen them. He had a sort of V-shaped trough on four legs.

When you bring home a truck or trailer load of cut logs the first piece that gets unloaded is your stand. You want to handle the logs a minimum number of times to maximize your efficiency in the process. You might as well process and cut the logs as you unload them from the truck or trailer.

The quicker you process the logs the easier it is to move them to your long-term storage area. It is easier moving a heavy cut log from your truck or trailer directly onto a stand and cutting into smaller pieces. If you unload the logs and move them to a process area you have to raise the heavy log and position it onto your "log stand" to cut it, this requires extra equipment or more stress on your back picking up the heavy log.

The quicker you process the logs the easier it is to move them to your long-term storage area. It is easier moving a heavy cut log from your truck or trailer directly onto a stand and cutting into smaller pieces. If you unload the logs and move them to a process area you have to raise the heavy log and position it onto your "log stand" to cut it, this requires extra equipment or more stress on your back picking up the heavy log.

I've been thinking like MIke on this. Now I'm using a osage orange stump as my cutting stand but I can't back the truck all the way to it so I have to move logs about 25' to load them onto the stump. That's too hard on my back so I'm planning to make a stand that is just a bit shorter than the tailgate of my truck . That way I can just shift them onto the stand and process them before I have to move them any distance. Since I have a tar and chip drive I'll need to catch the sawdust but a tarp under the stand will do that.When you bring home a truck or trailer load of cut logs the first piece that gets unloaded is your stand. You want to handle the logs a minimum number of times to maximize your efficiency in the process. You might as well process and cut the logs as you unload them from the truck or trailer.

The quicker you process the logs the easier it is to move them to your long-term storage area. It is easier moving a heavy cut log from your truck or trailer directly onto a stand and cutting into smaller pieces. If you unload the logs and move them to a process area you have to raise the heavy log and position it onto your "log stand" to cut it, this requires extra equipment or more stress on your back picking up the heavy log.

Agreed.When you bring home a truck or trailer load of cut logs the first piece that gets unloaded is your stand. You want to handle the logs a minimum number of times to maximize your efficiency in the process. You might as well process and cut the logs as you unload them from the truck or trailer.

The quicker you process the logs the easier it is to move them to your long-term storage area. It is easier moving a heavy cut log from your truck or trailer directly onto a stand and cutting into smaller pieces. If you unload the logs and move them to a process area you have to raise the heavy log and position it onto your "log stand" to cut it, this requires extra equipment or more stress on your back picking up the heavy log.

Often, the logs I acquire are just too heavy for me to be slogging around, or even lifting. I position my saw buck right behind the truck, jack the back of the truck up to match the heights so the log can be rolled onto the stand. Large logs have to be pulled off with a come-along attached to a convenient tree. The logs are then cut into turning blanks and put into plastic bags, one each, tightly wrapped.

Once all of it is processed into blanks, I rough turn all of it. All done while the wood retains its full moisture.