I really like my 1624-44 Nova Lathe with belt drive but there are times that I'd like to run it slower than the slowest speed. Nova no longer offers their DVR motor upgrade (it was too expensive and there were several reports of problems with it, anyway). We are using an autotransformer on an antique desk fan and I thought maybe I could do the same on my lathe. The lathe motor is rated at 13.5 amps but Variac makes a reasonably priced autotransformer rated at 20 amps. The lathe has a single phase 1 1/2 HP induction motor. Would there be any problems with using a autotransformer to slow it down?

-

November Turning Challenge: Puahala Calabash! (click here for details) -

Congratulations to Ted Pelfrey for "Forest Floor" being selected as Turning of the Week for November 4, 2024 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can I use an Autotransformer on my Lathe?

- Thread starter Steve Shelton

- Start date

I’m not an electrical engineer.

Auto transformer lowers voltage. Lowering voltage on an induction motor causes overheating. It works on a fan because a slow moving fan requires much less torque (power) than a fan at full speed.

Auto transformer lowers voltage. Lowering voltage on an induction motor causes overheating. It works on a fan because a slow moving fan requires much less torque (power) than a fan at full speed.

I believe if you ensure you do not exceed the amp rating of the motor you will end up with significant torque loss at reduced voltage in trying to achieve the lower speeds. If torque is not an issue, you may be able to dissipate the heat with a blower moving enough air across the motor.

If there was a great way to cheaply add a variable electronic speed option to an AC motor, don't you think people would lining up to buy one by this point in time?

Last edited:

It won’t work.

Tim

Tim

- Joined

- Feb 28, 2021

- Messages

- 1,368

- Likes

- 1,205

- Location

- Roulette, PA

- Website

- www.reallyruralwoodworks.com

what Others have said. I would not risk an expensive lathe motor (that may or may not be hard to find replacement for) but instead, likely would find a way to chuck up a drive pulley to drive the spindle and then pick up a cheap motor somewhere that I could control by the variable resistor If you need slower speeds than what it can provide for, but require it to be able to power through something like a gouge cut or scrape, you may want to consider a new or different lathe, but if it was for something like low speed sanding (or rotisserie style slow turning for finishing) then an accessory drive motor as I mentioned, might do the trick instead

- Joined

- Jan 27, 2005

- Messages

- 13,022

- Likes

- 5,426

- Location

- Dalworthington Gardens, TX

- Website

- pbase.com

The power line frequency (nominally 60 Hz), not the applied voltage, controls the speed of an AC induction motor. Reducing the voltage would cause the current to increase to maintain the torque. As previously mentioned by others this would result in the equivalent of a "brownout" condition and overheating. Depending on the torque load and applied voltage drop, it's possible that you could "cook" the motor, but not in a good way.

this would work. A bit more than an autotransformer but still cheaper than replacing motor and drive.

- Joined

- Jan 27, 2005

- Messages

- 13,022

- Likes

- 5,426

- Location

- Dalworthington Gardens, TX

- Website

- pbase.com

this would work. A bit more than an autotransformer but still cheaper than replacing motor and drive.

No, it would not work in this or any application that uses AC induction motors or any AC motor with a start winding, capacitor, and centrifugal switch. These single-phase variable-frequency inverters are meant to be used with PSC (permanent split capacitor) or shaded-pole induction motors. Typical applications are air handlers and pumps where very low torque is needed for starting and low-speed operation.

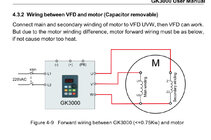

@Bill Boehme , the user guide shows how to connect motors that have start windings, capacitors and centrifugal switch. On page 58 It also specifies using open loop vector control for “machine tools”. This is what led me to think it’s for more than just fans and pumps.

The manual referenced is for a VFD that can operate from a single phase line. The connection diagram shows a single phase line into the VFD and a 3 wire connection to a 3PH induction motor. The way the VFD works is to rectify the incoming power then rebuilding a 3phase output at the voltage and frequency needed. Example: for a 3ph 230 volt motor if the VFD is set for 50% the output would be 115 volts at 30 Hz.@Bill Boehme , the user guide shows how to connect motors that have start windings, capacitors and centrifugal switch. On page 58 It also specifies using open loop vector control for “machine tools”. This is what led me to think it’s for more than just fans and pumps.

This diagram from the manual I linked clearly shows a single phase motor. It has a main coil and a secondary or starting coil. A three phase motor has three coils. The description is single phase input single phase output.

Pages 8–11 walk through the different ways the capacitor and switch could be connected, and how to bypass them when using this vfd

Pages 8–11 walk through the different ways the capacitor and switch could be connected, and how to bypass them when using this vfd

Attachments

Last edited:

Yes, you can buy single phase to single phase VFDs.