Hi,

I've been using shellac as a finish, and I thought I was really liking it. I'm using a 1lb cut from flakes.

Today I went out to buff a few pieces. I use the beall 3 wheel system. First wheel is some kinda weird red stuff if that matters. I set the wheel at about 1600 rpm which is slower than a slow speed grinder and I think they show it being used with just a regular grinder so I don't think it's too fast.

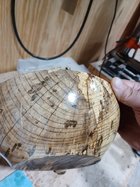

So as soon as I put the wheel to the piece it starts ... Rolling up a layer of finish. Idk quite how to describe it, just all this finish starts moving up and I have to sort of herd it up and off of an edge. I have included a pic. I tried applying very little pressure but that just made a blurry mess.

I mean I guess I must be putting too much shellac on? But ... It didn't seem that way to me. In the picture you can see the unbuffed part of the bowl as well.

Any help would be greatly appreciated.

Thanks

Raif

I've been using shellac as a finish, and I thought I was really liking it. I'm using a 1lb cut from flakes.

Today I went out to buff a few pieces. I use the beall 3 wheel system. First wheel is some kinda weird red stuff if that matters. I set the wheel at about 1600 rpm which is slower than a slow speed grinder and I think they show it being used with just a regular grinder so I don't think it's too fast.

So as soon as I put the wheel to the piece it starts ... Rolling up a layer of finish. Idk quite how to describe it, just all this finish starts moving up and I have to sort of herd it up and off of an edge. I have included a pic. I tried applying very little pressure but that just made a blurry mess.

I mean I guess I must be putting too much shellac on? But ... It didn't seem that way to me. In the picture you can see the unbuffed part of the bowl as well.

Any help would be greatly appreciated.

Thanks

Raif