I was watching a video on bowl from a board cut on the lathe and tried out the technique today. With a sharp parting tool tool its pretty easy to do. That got me to thinking about using the cutters on coring systems to cut the board with to allow for a more curved profile with less wasted wood. I have a oneway system which would be a bit limiting. Has anyone ever tried this with a McNaughton set?

-

April 2025 Turning Challenge: Turn an Egg! (click here for details) -

Congratulations to Kelly Shaw winner of the March 2025 Turning Challenge (click here for details) -

Congratulations to Ellen Starr for "Lotus Temple" being selected as Turning of the Week for 21 April, 2025 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bowl from a board with coring tools?

- Thread starter Gary Beasley

- Start date

- Joined

- Apr 27, 2004

- Messages

- 9,160

- Likes

- 5,761

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

I was watching a video on bowl from a board cut on the lathe and tried out the technique today. With a sharp parting tool tool its pretty easy to do. That got me to thinking about using the cutters on coring systems to cut the board with to allow for a more curved profile with less wasted wood. I have a oneway system which would be a bit limiting. Has anyone ever tried this with a McNaughton set?

You may have hit on an innovative approach to getting a nice curve.

The thickness of the cut would be the downside of using a coring blade.

I’ve used the technique to make roofs for full size birdhouses.

Easy way to find out is to draw the cuts. Then see If the rings overlap enough when stacked.

If the don’t you can cut rings from two boards with off sets to use a rings from the two boards to make a stack.[/QUOTE]

- Joined

- Jan 27, 2005

- Messages

- 13,092

- Likes

- 5,551

- Location

- Dalworthington Gardens, TX

- Website

- pbase.com

I'm almost positive that wouldn't work. The McNaughton would take a minimum of a half-inch kerf and very likely wider as the curve becomes more shallow and wants to drift to the outside of the curve. Also, it isn't designed to cut through the wood and would be difficult to control when the outside of the cutter breaks through. The width of the kerf would probably prevent stacking.

Lance Mirrer

AKA "taxman"

When I've seen the multi flat board approach, they've used a band or jig saw. With either of these tools, I suspect cutting at an angle would lessen the wasted wood. Although I am not sure the extra work would provide a meaningfully better curve than the row of circles cut with a sharp bowl gouge.

I fear the attempt to pre-cut the curve is ripe with opportunities for one level to not line up where it should for the final shape.

I fear the attempt to pre-cut the curve is ripe with opportunities for one level to not line up where it should for the final shape.

Gary Asher (who goes by 'thePapa1947' on Youtube) recently posted a video in which he made a BFB with curved sides by varying the angle the rings were cut at with a thin parting tool. Here's a link to his video:

View: https://youtu.be/XvyJreJA1eg

wasted wood.....bil made that comment many years ago after watching bowl turning...... Ha..... he was a engineer

I'll have to try something similar with the Ringmaster.

john lucas

AAW Forum Expert

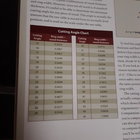

I may start playing with bfb again. Carol rothman has a scroll saw book on making bowls and has a chart near the end that shows angles. I designed and built a new tool to do this but then life got in the way and I have not used it yet. The metal cutting parting tool is wider at the top and only 1/2" tall so it should work better when cutting the small rings.

Attachments

I would have to draw it up to know for sure but I am afraid that the kerf taken by even the smallest McNaugton knife would be too wide to work - at least for the whole bowl. As others have noted the secret to getting a nice curve is to vary the angles and minimize the loss from the kerf to ensure that the rings stack with sufficient wall thickness to turn. The bowls I have made this way with curved sides start out with steep sided rings on the bottom (often about 60 degrees) gradually transitioning to as acute as 30 degrees for the last ring. The smallest steepest sided rings need to be cut precisely with the bandsaw to ensure that there is enough wall thickness to allow for final turning after glue up. There is very little room for error on this ring. I made an auxiliary table for my bandsaw that lets me get those last couple of rings where the angle is less than 45 degrees (the limit of the table tilt on my bandsaw). You might be able to take hybrid approach and use the bandsaw for the steeper sided lower rings and use the McNaughton for the upper rings with the more accute angles. There is usually much more wood to turn away there so the loss from the thicker knife might not be an issue. (And it would save you from having to build an auxiliary table).

Bowls from a board don´t have to be conical

This is a short description of how I make bowls from a board, cutting out the rings on the lathe with varying angles.

Well, it could be done. Not sure if it would be worth the effort. If you have ever seen the video on the New Holland Bowl Mill, they have a large coring tool that they use for the outside roughing cut of a large bowl blank, and use different blades for the inside cores. Their stuff is kind of rough, and not as well finished as most of our bowls are. I would think that a gouge would be more efficient. I don't think even I would approach this type of bowl with a scraper, and all coring systems are scrapers.

robo hippy

robo hippy

Considering the width of the cut on most coring tools you would need to scale up the thickness of the board to get away with doing it. I would think along the lines of a 1” to 2” thick glueup.

I did a little experimenting with a thick chunk of waste wood I had laying around. I mounted it on a chuck and cored it all the way through, then laid the inside on the outside cut. Because of the way the cut is curved you end up with a bit more overlap than a straight cut will give you. In the case the wood was about an inch and a half thick. I got more than an inch wide contact area to glue up and when the bowl was turned to a half inch wall sides angled at about 45 degrees the contact was a half inch wide.

A few pictures, found out the wood was hiding some enormous bug holes so it was never finished out.

A few pictures, found out the wood was hiding some enormous bug holes so it was never finished out.

Last edited:

Oh, now I understand the original question.... Gary's pictures explained it.... DUH! I have seen parting tools used for this, so a coring tool would work also. I was thinking of the finished glue up and then taking a coring tool to it to rough turn it....

robo hippy

robo hippy