I've been using Sharpies to sign my bowls, but they fade, and have tried a pyro pen but it's unwieldy to use and I can't get the lettering very small even with the finest ball tip. I'm going to try some Sakura Pigma pens next, but I'm wondering about using a laser engraver. In this month's AW, p.20, there's a description of the LaserPecker unit. Does anyone have experience, good or bad, with this type of unit? The online description and video didn't impress me - taking a picture of something with your phone then engraving from that doesn't sound to me like it would produce good results. Are there any other relatively inexpensive units I could look at? (I'm not able to go for the multi thousand dollar units.)

-

Beware of Counterfeit Woodturning Tools (click here for details) -

Johnathan Silwones is starting a new AAW chapter, Southern Alleghenies Woodturners, in Johnstown, PA. (click here for details) -

Congratulations to Keven Jesequel for "Big Leaf Maple" being selected as Turning of the Week for April 15, 2024 (click here for details) -

Welcome new registering member. Your username must be your real First and Last name (for example: John Doe). "Screen names" and "handles" are not allowed and your registration will be deleted if you don't use your real name. Also, do not use all caps nor all lower case.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

signing bowls with laser

- Thread starter Karl Best

- Start date

- Joined

- Apr 27, 2004

- Messages

- 8,626

- Likes

- 4,953

- Location

- Lakeland, Florida

- Website

- www.hockenberywoodturning.com

A long long time ago

I got some advice from Christian Burchard. I used to sign a big legible name on the bottom.

Christian said some thing like - someone picks up a nice piece of your work and turns it over to see this, make your signature small and inconspicuous.

I said - no one will be able to read it.

Christian said - they will know who you are.

Ever since I’ve been doing a small signature with a pyrography pen. Write slow with medium power. Leaves a tactile signature that even works on ebonized pieces.

there is a certain philosophy that hand made work should be hand signed.

It’s your work you get to decide.

If you want to use a machine to sign your work or branding iron that’s fine because it’s your work.

I got some advice from Christian Burchard. I used to sign a big legible name on the bottom.

Christian said some thing like - someone picks up a nice piece of your work and turns it over to see this, make your signature small and inconspicuous.

I said - no one will be able to read it.

Christian said - they will know who you are.

Ever since I’ve been doing a small signature with a pyrography pen. Write slow with medium power. Leaves a tactile signature that even works on ebonized pieces.

there is a certain philosophy that hand made work should be hand signed.

It’s your work you get to decide.

If you want to use a machine to sign your work or branding iron that’s fine because it’s your work.

Last edited:

You could also have just about any type of round disc material laser engraved with your trade mark, name, date, website and press or glue them into a recess in the work piece.

Reasonably priced if you have them engrave a quantity on one order.

Reasonably priced if you have them engrave a quantity on one order.

My hand writing is shaky and inconsistent, and makes it look like I'm more brain damaged than I really am  , so the idea of some better way to mark my work is appealing. I've tried pyrography, but it looks even worse than my regular writing. I've tried various kinds of pens, but they weren't finish proof in the least and most would bleed into the grain. I finally tried a Sakura Black Pigma Micron PN archival pen and once dried, it's held up to any finish I've tried including several wipe on finishes. I like the idea of having some kind of disks engraved with a logo and basic info on it, then signing my name and date with the Micron pen. I should be able to scrawl that much in an acceptable way. Sometimes...

, so the idea of some better way to mark my work is appealing. I've tried pyrography, but it looks even worse than my regular writing. I've tried various kinds of pens, but they weren't finish proof in the least and most would bleed into the grain. I finally tried a Sakura Black Pigma Micron PN archival pen and once dried, it's held up to any finish I've tried including several wipe on finishes. I like the idea of having some kind of disks engraved with a logo and basic info on it, then signing my name and date with the Micron pen. I should be able to scrawl that much in an acceptable way. Sometimes...

No where does it say that a signature must be legible. Check the old painting masters. A better selling point than a legible signature is a display note that says "Signed work by John Doe"

I've been on the CNC learning curve to embellish my turnings and have played a lot with lasers and routers. A small CNC ( 2ft x 2 ft or slightly bigger) would do what you want and a lot more. A simple machine running on GRBL would allow the use of a 6 watt diode laser which would have more than enough power to burn an image of your signature or anything else. They are not powerful enough to cut any significant thickness though. I have also used a 3 watt diode laser but it had trouble with white woods like baltic birch. The darker the wood the better the burn because of the absorbed energy. I made my own CNC machines, but I've read several people have tried those little import laser engravers with success.

Check out Unemployed Redneck Hillbilly Creations on YouTube:

https://www.youtube.com/channel/UCzM1HPpclXyriKNAvr5m5qA He plays with a little laser in a couple videos.

The more popular CNCs like Shakeopo are also very useful tools, if pricey. The best laser software I've used is called Lightburn. After climbing the learning curve of the CNC world, you will find that program has some really good features including being able to use a camera to locate the workpiece on your table and engrave on it. I threw a paint stir stick on mine for example, and burned some lettering on the handle even though it was crooked to both the X and Y axes. The important thing with those little lasers is 1. EYE Protection with Proper Laser filter glasses, and 2. Z height because their depth of focus is only about 5mm. There is a lot to learn about CNCs but when you can realize how useful the things are, it's a good curve to climb IMHO.

Check out Unemployed Redneck Hillbilly Creations on YouTube:

https://www.youtube.com/channel/UCzM1HPpclXyriKNAvr5m5qA He plays with a little laser in a couple videos.

The more popular CNCs like Shakeopo are also very useful tools, if pricey. The best laser software I've used is called Lightburn. After climbing the learning curve of the CNC world, you will find that program has some really good features including being able to use a camera to locate the workpiece on your table and engrave on it. I threw a paint stir stick on mine for example, and burned some lettering on the handle even though it was crooked to both the X and Y axes. The important thing with those little lasers is 1. EYE Protection with Proper Laser filter glasses, and 2. Z height because their depth of focus is only about 5mm. There is a lot to learn about CNCs but when you can realize how useful the things are, it's a good curve to climb IMHO.

For a signature you can get a little NEJE diode laser for a couple hundred dollars. I hand turned the work, I prefer to hand sign it.

I've been signing all of my work with a laser engraver for several years. I use a 30W Epilog Helix engraver. I also use it for texturing and other embellishments. If you want a signature that looks handwritten it is not difficult to take someone's handwritten signature, scan it and turn it into vector artwork for engraving. It's important to remember that not all species of wood go dark when engraved. Some species do not change colour at all. In the cases where there is very little contrast between the wood and the engraving there are a few different techniques for infilling the engraving with colour.

I've also used the laser to create various custom measuring gauges and calipers out of acrylic or BB plywood.

I've also used the laser to create various custom measuring gauges and calipers out of acrylic or BB plywood.

Epoxy Domes come in lots of sizes, and have adhesive backs. Easy and inexpensive to attach your artwork/signature/logo. This one is 1" in diameter, and resides inside a 3" diameter throw-top.

The thing about lasers is that you can put virtually any design you want on the wood. That's great. But it has downsides, too. Every turning you want to lase will probably be different and require you to change the laser output, especially for wet turnings. The LaserPecker looks pretty cool and the way it's setup allows you to easily aim it at your work. But just know that it will take a lo-o-o-o-ng time to lase a nice logo/signature. These aren't epilog's. Lasers in the lower price ranges print in the same manner as old dot matrix printers: One dot across the whole width, then the next lower dot across the whole width. Epilogs and the more expensive lasers with GRBL control boards can lase letter outlines and images rather quickly. But you will spend a lot more to buy one ready to go.

You can update the controller board on the cheap laser (maybe not the laserpecker, I haven't seen its internals) burners such as the ISMA (image attached) with laser diodes up to 3000mw are good for this. That burner has an open bottom that allows you to suspend it in a frame above what you'd like to engrave so the size and shape of the object doesn't matter greatly as long as the target is relatively flat. That works great, once you know the settings for the material you need to burn you're golden. It's great for dry woods. YMMV with wet turnings.

You can update the controller board on the cheap laser (maybe not the laserpecker, I haven't seen its internals) burners such as the ISMA (image attached) with laser diodes up to 3000mw are good for this. That burner has an open bottom that allows you to suspend it in a frame above what you'd like to engrave so the size and shape of the object doesn't matter greatly as long as the target is relatively flat. That works great, once you know the settings for the material you need to burn you're golden. It's great for dry woods. YMMV with wet turnings.

Actually, even the more expensive lasers like Epilog, Trotec and Universal engrave in raster mode one line of dots at a time. In vector mode the lasers will follow an outline but that is generally only used for cutting or, at lower powers, engraving an outline of something. If you are engraving a bitmap image or even a vector image with line widths greater than about .004", the lasers will always raster engrave. However, they are faster only because of the higher power output. The lowest power machines from the above vendors are 30 watts, 10x the power of a 3000mW device.Lasers in the lower price ranges print in the same manner as old dot matrix printers: One dot across the whole width, then the next lower dot across the whole width. Epilogs and the more expensive lasers with GRBL control boards can lase letter outlines and images rather quickly.

Every turning you want to lase will probably be different and require you to change the laser output, especially for wet turnings.

This is true for every laser job for any type of laser as different materials have different characteristics even between different species of wood. However, this is not a big deal and only requires tweaking the laser settings (primarily power and speed) when you are sending the job to the laser. It doesn't take long before you are able to fairly accurately estimate the appropriate settings for the different materials you work with be it glass, wood, leather, cardboard, paper, anodized aluminum, etc. I always use scrap material to do test engravings/cuttings on unfamiliar materials using the manufacturer's recommended settings as a starting point. I find that the optimal setting I've found for hardwoods work 90% of the time on just about any dry hardwood. This will change if there is a hard finish on the wood or if I'm masking areas with tape or masking paper.

I recently purchased the LaserPecker. It cost $300. It does a great job for me. I find that if the engraving is not dark or deep enough, I can simply have it re-engrave (as long as I don’t move the object. Here in an example. It was one of my first ones. I have experimented and have gotten better but this one is pretty good.

Attachments

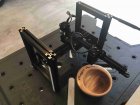

For a while, I was signing pcs with a pure carbon stamp that I heated with my propane torch. But, in order to both sign and add embellishments, I bought a 7W laser engraver for $300 and build a vertical structure to raise and lower it for the different heights of the pcs. I admit that part of my intent was to have fun and I accomplished that also.

Attachments

john lucas

AAW Forum Expert

I will admit I've looked at those and it really looks cool. However for that price I can sign an awful lot of pieces with my Dremel engraver. My lack of computer skills would also probably cause problems when I tried to use one even if I could buy it. Oh well. Guess I'll stay a Neanderthal.

oh Boy, this has got me looking at Laser Engravers anywhere from $200 to $6K.

I've got to stop reading these threads....

I've got to stop reading these threads....

For a while, I was signing pcs with a pure carbon stamp that I heated with my propane torch. But, in order to both sign and add embellishments, I bought a 7W laser engraver for $300 and build a vertical structure to raise and lower it for the different heights of the pcs. I admit that part of my intent was to have fun and I accomplished that also.

That's a significantly beefier laser that what is in a LaserPecker. Nice setup!

For a while, I was signing pcs with a pure carbon stamp that I heated with my propane torch. But, in order to both sign and add embellishments, I bought a 7W laser engraver for $300 and build a vertical structure to raise and lower it for the different heights of the pcs. I admit that part of my intent was to have fun and I accomplished that also.

Sounds like a cost effective solution. I'm curious, at 7W how long does it take to engrave that name on your bowl? Does the engraver require any sort of dedicated software? What file format do you need to feed it? How do you focus it on the work surface? Do you need to wear special glasses to protect your eyes from laser radiation?

I have a lot of experience using higher end lasers (Epilog owner, Trotec at work, Universal at previous job) but I'm very intrigued by these lower end, consumer affordable devices.

I noticed that Larry Martin (The Wood Whirler) is using one of the 40 watt cabinet style CO2 lasers (the ones with an Epilog look) to sign his work. They run under $400 on ebay. He did a serious case mod on his unit by making a cut out in bottom to stick the bottoms of his pieces through for lasing.

https://cadence.moe/cloudtube/video/pAPz002lFdI Skip to 18:40 for his commentary on the laser.

View: https://www.youtube.com/watch?v=xCzx2MJ-CsQ

This one is the initial review/setup of the laser.

https://cadence.moe/cloudtube/video/pAPz002lFdI Skip to 18:40 for his commentary on the laser.

This one is the initial review/setup of the laser.

I use a sharpie, I put at least one coat of finish on the bowl before I sign it. It will stay there for years and never fade. Wood like red oak with open pores wood you may need more coats of finish before signing.

I always used a wood burning pen, tricky, but it works

odie

TOTW Team

- Joined

- Dec 22, 2006

- Messages

- 7,109

- Likes

- 9,701

a dremel engraver costs less than $30, and will last virtually forever. Take the stylus to the grinder and sharpen it up and its surprising how small you can get your signature. I'm in the camp that feels their signature is unique no matter how difficult to read.

Early on in my turning I was fortunate enough to have some time with a renowned turner in his shop. Got to see and even handle some of his work and that of other well respected turners he knew. I was surprised at how incredibly tiny his signature was - engraved with a dremel, it was actually difficult to find on some pieces.

If your work is good enough people will find a way to figure out who made it...

Early on in my turning I was fortunate enough to have some time with a renowned turner in his shop. Got to see and even handle some of his work and that of other well respected turners he knew. I was surprised at how incredibly tiny his signature was - engraved with a dremel, it was actually difficult to find on some pieces.

If your work is good enough people will find a way to figure out who made it...

I've used a woodburning pen for years but recently I was gifted a Laserpecker and am quite pleased with it. Apparently I can no longer attach a video but if you take a look at the thread Signing your work I was able to post a quick 1 minute vid and pictures.I recently purchased the LaserPecker. It cost $300. It does a great job for me. I find that if the engraving is not dark or deep enough, I can simply have it re-engrave (as long as I don’t move the object. Here in an example. It was one of my first ones. I have experimented and have gotten better but this one is pretty good

I use a Sakura Pigma pen to sign with. Sharpies get dissolved by finishes and absorb into the wood fibers, looking very fuzzy. The Pigma pen/ink (archival ink) do not dissolve with typical finishes and do not disperse much at all into the wood fibers, providing clean lines. I used a dremel engraver for a while, but its much slower than a pen. Once I found a pen that didnt “fuzz” into the wood or dissolve into finishes, its been all I use. Quick and easy.

I prefer the signing of artwork, or craft work. I think laser, always the same, looks commercial, and not necessarily in a good way.

Plus, the expense of getting into it is more than the benefit I might receive.

So, I sign my work. Just my signature, which is anything but legible, but very identifiable. And I print the species of wood.

I‘ve been using pigment paint pens from Molotow. I use the black fine liner, 1mm. I usually write on the bare wood, then finish over. However, since it’s alcohol based, I sign over shellac, but still under the wax or whatever. It’s nice and sharp, doesn’t bleed (in my experience) and doesn’t fade. One of my personal bowls of willow oak, finished with walnut oil has been washed with soap and water at least 50 times. The signature is as sharp and black as the day I finished it.

I will check out the Sakura pens too. Glad for the suggestion.

A big plus for me is that the pens cost a few bucks and the signing process takes about a minute.

Plus, the expense of getting into it is more than the benefit I might receive.

So, I sign my work. Just my signature, which is anything but legible, but very identifiable. And I print the species of wood.

I‘ve been using pigment paint pens from Molotow. I use the black fine liner, 1mm. I usually write on the bare wood, then finish over. However, since it’s alcohol based, I sign over shellac, but still under the wax or whatever. It’s nice and sharp, doesn’t bleed (in my experience) and doesn’t fade. One of my personal bowls of willow oak, finished with walnut oil has been washed with soap and water at least 50 times. The signature is as sharp and black as the day I finished it.

I will check out the Sakura pens too. Glad for the suggestion.

A big plus for me is that the pens cost a few bucks and the signing process takes about a minute.

I too use the Pigma Micron in 005 or 008 on the wood before finishing. I have found no finish that affects the Pigma archival ink. Just name and type of wood.