odie

TOTW Team

- Joined

- Dec 22, 2006

- Messages

- 7,116

- Likes

- 9,817

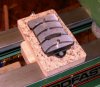

Veritas carbide scraper burnisher

Just wondering if anyone is using this little device to improve the burr on their scrapers.....?

I probably haven't touched mine since last century. (!)

If this thing works, I'm probably not doing it right......does it work for you?

If so, then I'm probably not the only one who would appreciate a little advice on it's proper use.

ooc

I took the photo directly from the csusa online catalog, but mine is the exact same item......

Just wondering if anyone is using this little device to improve the burr on their scrapers.....?

I probably haven't touched mine since last century. (!)

If this thing works, I'm probably not doing it right......does it work for you?

If so, then I'm probably not the only one who would appreciate a little advice on it's proper use.

ooc

I took the photo directly from the csusa online catalog, but mine is the exact same item......