Hello, I've recently been given permission to harvest a few Osage Orange trees and would like to know what's been the best method for preparation for an easier turning vs. it being completely dry.

I don't turn wood (yet), but the wood turners I've worked with in the past are pretty specific about the osage orange. They'd prefer it not to be totally dry due to it's hardness. Since I've sourced most of my premium wood from a local lumber store, most of their wood is completely dry.

Now that I have access to the osage orange, I'll be able to provide them something a little easier to turn.

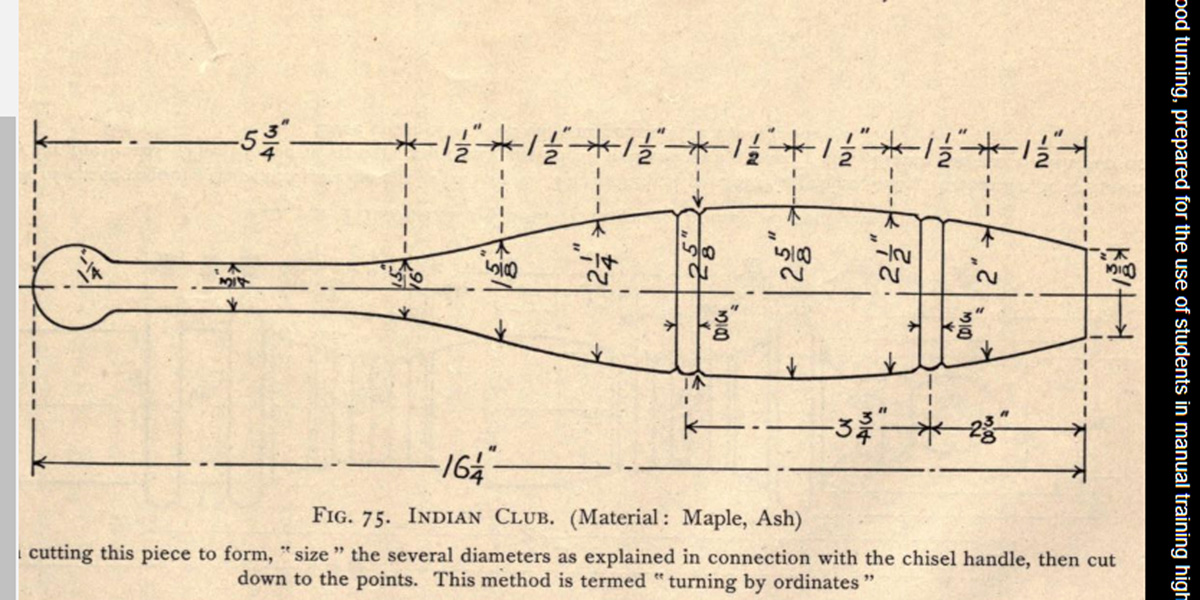

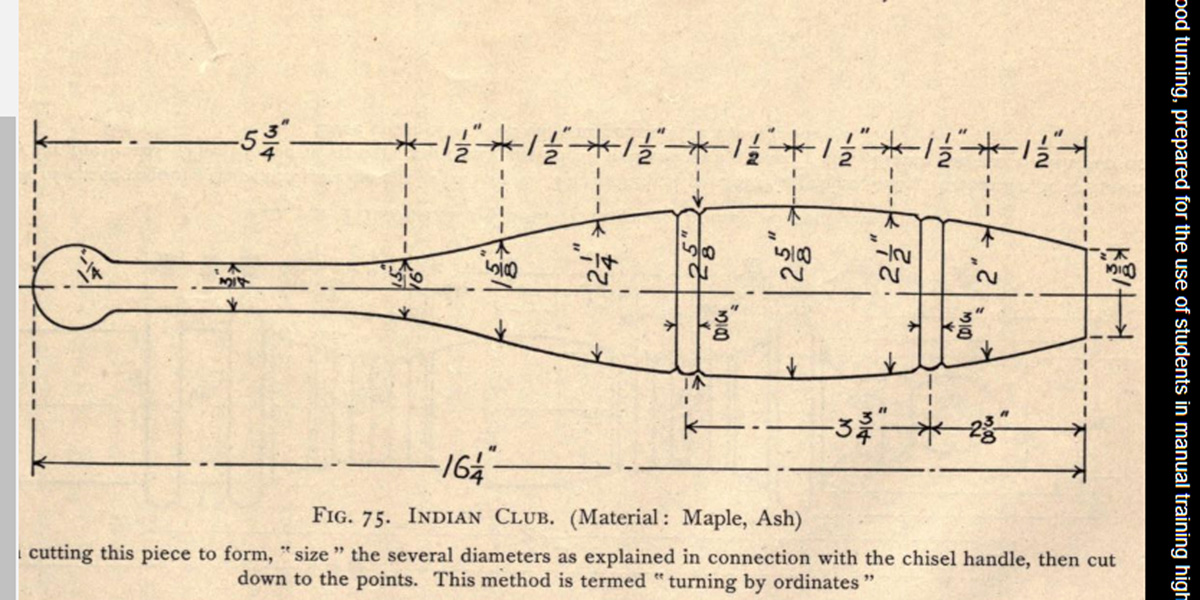

I was just curious if there are members that have a vast amount of experience turning osage orange and what preparation suggestions you have for freshly cut osage orange that will be turned to make Indian Clubs.

Thank you

I don't turn wood (yet), but the wood turners I've worked with in the past are pretty specific about the osage orange. They'd prefer it not to be totally dry due to it's hardness. Since I've sourced most of my premium wood from a local lumber store, most of their wood is completely dry.

Now that I have access to the osage orange, I'll be able to provide them something a little easier to turn.

I was just curious if there are members that have a vast amount of experience turning osage orange and what preparation suggestions you have for freshly cut osage orange that will be turned to make Indian Clubs.

Thank you